A two-dimensional metal oxide material called titanate nanosheets has remained pretty much off the radar of flatland materials expected to transform the worlds of electronics and optoelectronics. Its biggest claim to fame has been that it is pretty effective at cleaning up contaminants.

However, it would seem that titanate nanosheets history of being overlooked in the catalogue of 2D materials may have come to an end thanks to a serendipitous discovery by researchers in Japan.

Researchers at the RIKEN Center for Emergent Matter Science in Japan were experimenting with the material to see if they could get the nanosheets to break into more uniform pieces rather than the varied sizes they typically take. Unfortunately, they weren’t able to solve this problem. But they did discover that when the material was centrifuged in water, it changed from being transparent to taking on a deep purple color.

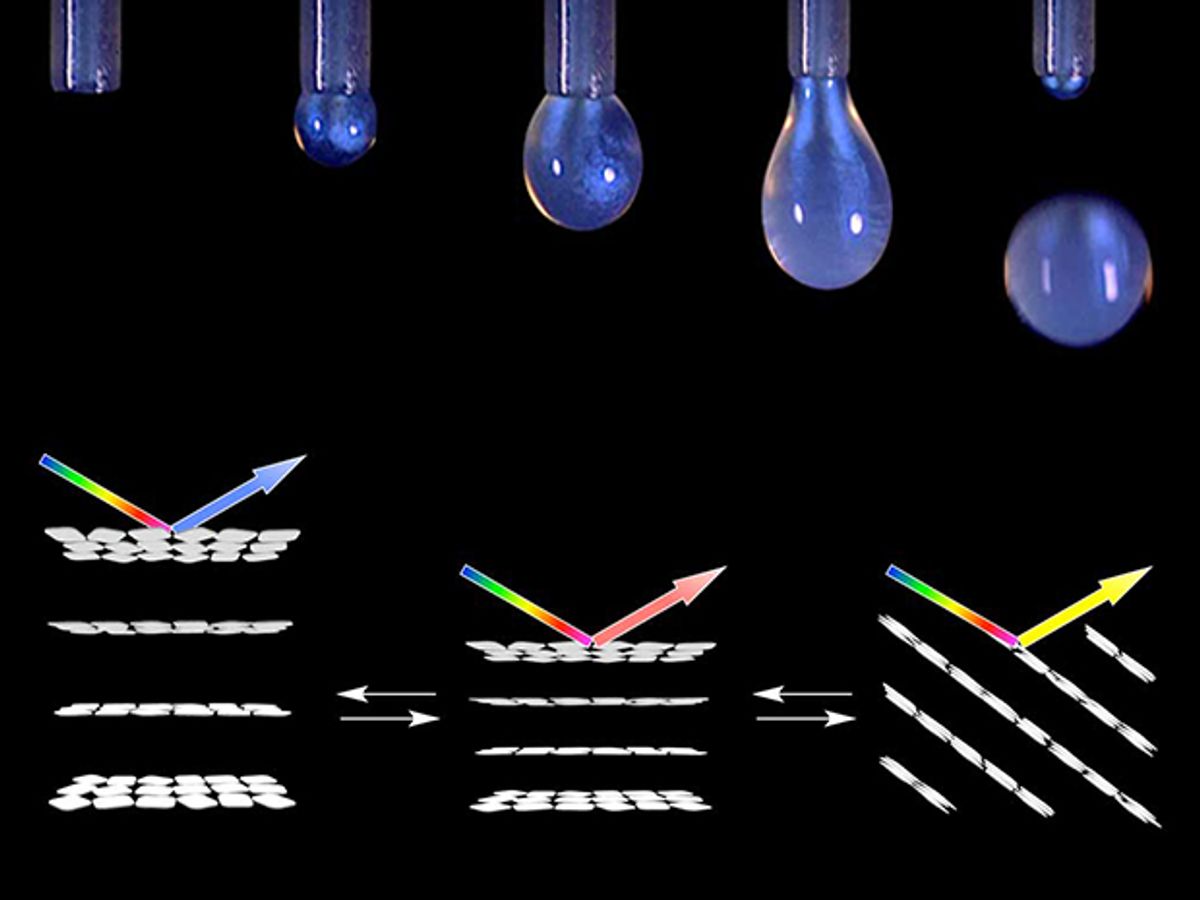

The resulting liquid, which the researchers have dubbed ‘photonic water’, is able to reflect light over the widest range of wavelengths ever reported: from the ultraviolet to the infrared. The researchers discovered that the photonic water changes color when exposed to chemical or magnetic forces that adjust the alignment of internal stacks of reflective nanosheet crystals. The discovery could ultimately lead to applications in telecommunications and lasers.

“When my student Koki Sano first told me about the color change on centrifugation, I couldn’t believe it,” said RIKEN’s Yasuhiro Ishida in a press release. “I thought it was contamination and asked him to repeat the experiment.”

It wasn’t contamination. What the researchers had observed was that the centrifuge had in fact eliminated an ionic contaminant that had blocked the natural electrostatic repulsive charge that exists between each of the nanosheets. With this contaminant removed, the nanosheets pushed each other away to form an ordered framework.

That was an attractive kind of self-assembly, but the researchers had to figure out what the new material could do other than make the liquid change color.

In research described in the journal Nature Communications, the researchers hit on the idea that the best way to know what the material is capable of is to control its structure and observe what happens. The researchers did this by changing the concentration of the nanosheets in the water from 0.50 to 0.09 percent. The results were significant: The wavelengths of the reflected light changed as they lowered the concentration.

Then the team improved the color output of the photonic water by using external magnetic fields that aligned the crystals into tightly ordered structures.

The researchers didn’t stop there. They then made small changes to the solution’s pH, which yielded distinct blue, green, and red color changes. The liquid proved far more sensitive to pH changes than conventional pH indicators.

The colors produced by the photonic water are termed structural colors, because the fluid contains nanostructures whose arrangement naturally reflect light in a way that falls into a visible wavelength range. This is not unlike how some fish are able to change color.

Ishida added: “Considering its stimuli responsiveness and wide-ranging color modulation, photonic water could find applications as near-infrared band filters in telecommunications or as variable photonic lasers.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.