Perovskite solar cells are one of the hottest prospects in clean energy research, offering good power outputs from low-cost materials that are relatively simple to process into working devices. But their rapid progress has not been without some stumbling blocks.

Firstly, the cells’ power conversion efficiency often varies depending on how it is measured, suggesting an underlying instability in the cells’ light-gathering perovskite materials. That’s bad news for photovoltaic panels that need to work for a decade or more. Secondly, researchers were struggling to extend the range of the light wavelengths that the cells could harvest, a key strategy for improving their efficiency beyond the 20 percent or so achieved by typical silicon or thin-film solar cells. Some of the field’s leading lights have spent much of last year grappling with these issues.

Now a team researchers in South Korea has developed a perovskite blend that addresses both these challenges, and delivers what they say is the highest-efficiency perovskite cell to date.

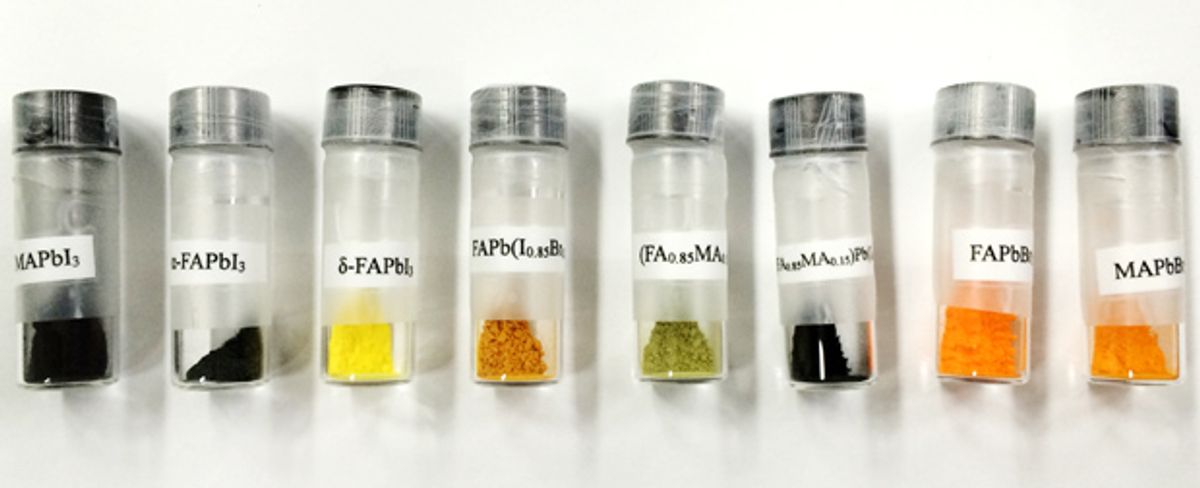

Sang Il Seok and colleagues at the Korea Research Institute of Chemical Technology in Daejeon blended one of the work-horse perovskite materials – methylammounium lead bromide —with a similar compound called formamidinium lead iodide.

Like methylammonium, formamidinium is a small, positively charged molecule made of carbon, hydrogen, and nitrogen. But formamidinium lead iodide absorbs light further into the near infra-red than its partner, potentially boosting the cell’s efficiency. Previous tests with the material had, however, shown that it was fairly unstable.

After testing several compositions, the researchers settled on an 85:15 mixture of the formamidinium and methylammonium perovskites. The resulting cell was much more stable and produced an average efficiency of 18.4 percent, they report this week in Nature. Seok says that this blend was also responsible for the record-breaking 20.1-percent-efficiency cell confirmed late last year by the US National Renewable Energy Laboratory in Golden, Colorado—the gold-standard in photovoltaic efficiency certification.

“In terms of absolute efficiency, this is probably the highest reported yet,” says Henry Snaith, a perovskite researcher at the University of Oxford, UK, whose Oxford Photovoltaics company aims to produce commercial perovskite cells by 2017. (Australian firm Dyesol announced this month that it would begin mass-manufacturing perovskite cells in 2018.)

Crucially, the Korean researchers’ cells do not suffer the same variability in efficiency that has plagued other devices. Efficiencies are often measured by plotting a curve of current against voltage—but for perovskites, the curves differ depending on whether the voltage is increasing or decreasing, an anomaly known as hysteresis that may have led to overestimates of perovskite performance in the past.

“People don’t really understand why this happens,” says Juan Bisquert, a photovoltaic researcher at James I University in Castellón de la Plana, Spain. But it implies that the structure of the perovskite changes in some way as current flows through it, he adds. Consequently, eliminating this hysteresis is a promising step toward ensuring the long-term performance of perovskite cells, and Bisquert expects that others working on perovskite solar cells will want to try Seok’s new recipe.

The Korean achievement also illustrates the benefits of a broader trend in the field. Rather than simply racing for higher efficiencies through trial-and-error recipe changes, scientists are spending more time understanding exactly how the perovskite’s structure and composition affect the cells’ electronic properties. “We are getting good performance; now we need to know why,” says Bisquert.