Perovskites have become the hottest material for solar cells because they are cheap and very easy to process. They’ve also been tapped for use in light-emitting diodes and lasers, but LEDs incorporating materials with the perovskite crystal structure have not been very bright.

But researchers at Florida State University (FSU) now report that they have made perovskite LEDs that are more than four times as bright as earlier versions. They have a brightness of over 10,000 candelas per square meter, comparable to that of organic LEDs and quantum dot LEDs.

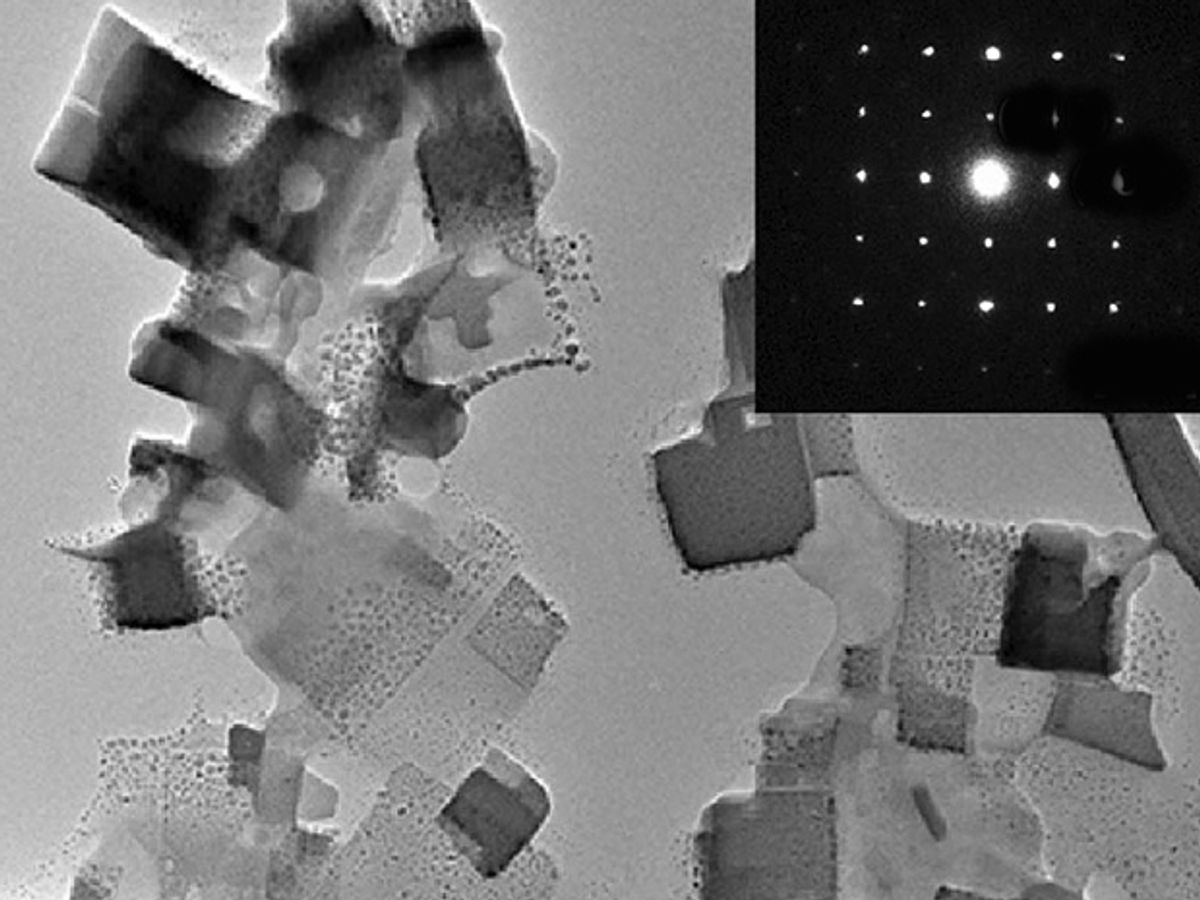

Instead of the perovskite thin films that others have used to make LEDs, the FSU team used flat perovskite nanoparticles, or nanoplatelets. Nanoparticles deliver a big efficiency advantage, says Hanwei Gao, a professor of physics at FSU. The small, single-crystal pieces have very few defects at which electrons and positively charged holes can recombine without producing a photon.

The researchers used common precursor materials and a simple chemical solution process to produce the highly crystalline nanoplatelets of the perovskite methyl ammonium lead bromide. They used the nanoparticles as the light emitting material in a conventional stacked architecture to make a bright green LED. Gao, professor of chemical engineering Biwu Ma, and their colleagues outlined the details in a paper in the journal Advanced Materials.

The new device also overcomes a common problem with perovskites: their penchant to quickly degrade when exposed to moisture. Because of this sensitivity to water, perovskite devices have to be made in glove boxes and also require expensive packaging. But the process that the FSU team uses to make the nanoplatelets leaves a layer of a water-repelling organic compound on their surfaces. Gao says that he and his colleagues made the new LEDs without a glove box and that the devices retained their brightness for more than a week when when exposed to humid Florida air.

But these LEDs are still a pretty early prototype. Right now, they need several volts to glow bright because the efficiency with which they convert electricity to light is low. In a practical LED, Gao says, “you need to inject charges, make sure they are confined in a small space so they can meet and recombine.” But the principal limiting factor for an efficient, bright LED is the emitter itself.

So, says Ma, “we’re making sure we have good emitters first. Now we need to do device engineering to make a practical device. It took a long time for other kinds of LEDs to reach a high efficiency level.”

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.