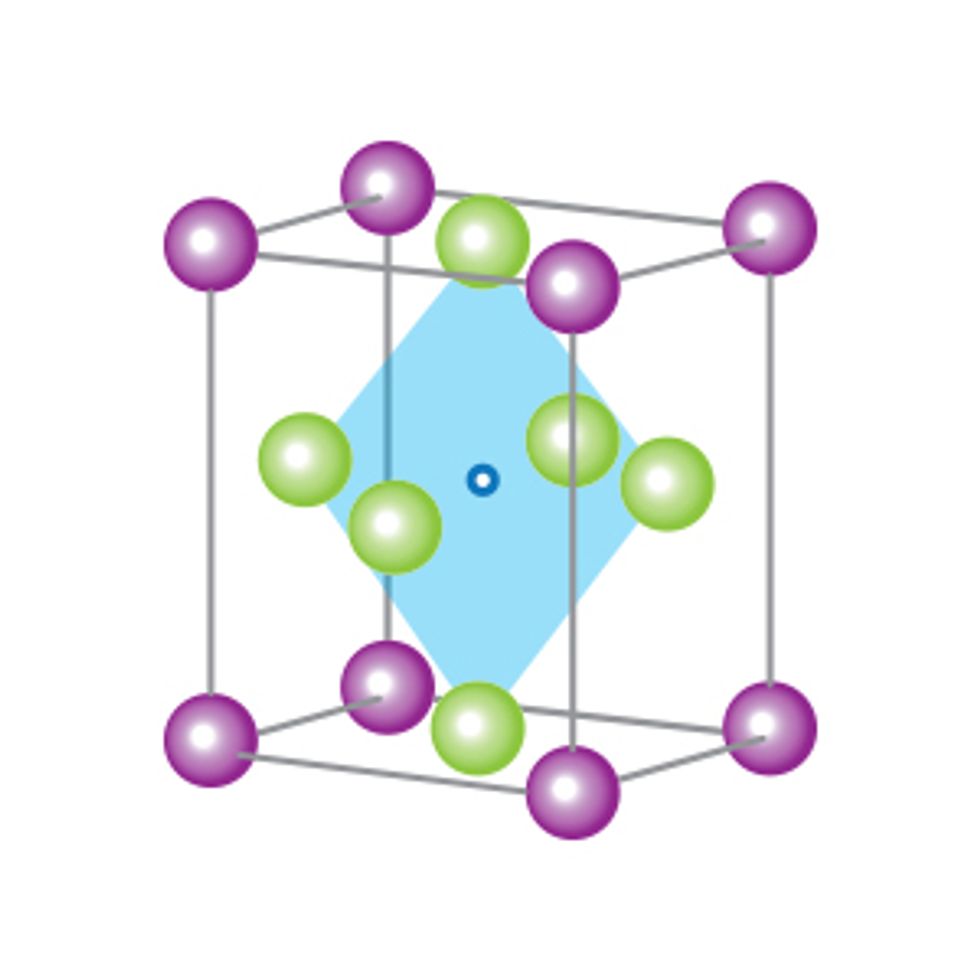

Five years ago, a new photo voltaic material made a rather low-key entrance on the solar power scene. Methylammonium lead tri-iodide belongs to a family of crystals known as perovskites, and a solar cell made from it converted light into electricity with an efficiency of just 3.8 percent—hardly likely to solve the world’s energy troubles.

Fast forward to 2014 and perovskites are soaring higher than anyone could have hoped. At a Materials Research Society meeting in April, materials scientist Yang Yang at the University of California, Los Angeles, revealed that his lab had made a 19.3-percent-efficient perovskite cell—good enough to rival some commercial crystalline silicon solar cells, which typically notch up 17 to 23 percent efficiency.

“I don’t know any group that works on photovoltaics that isn’t looking at perovskites,” says Henry Snaith, a physicist at the University of Oxford, in England, who is one of the leaders in the field.

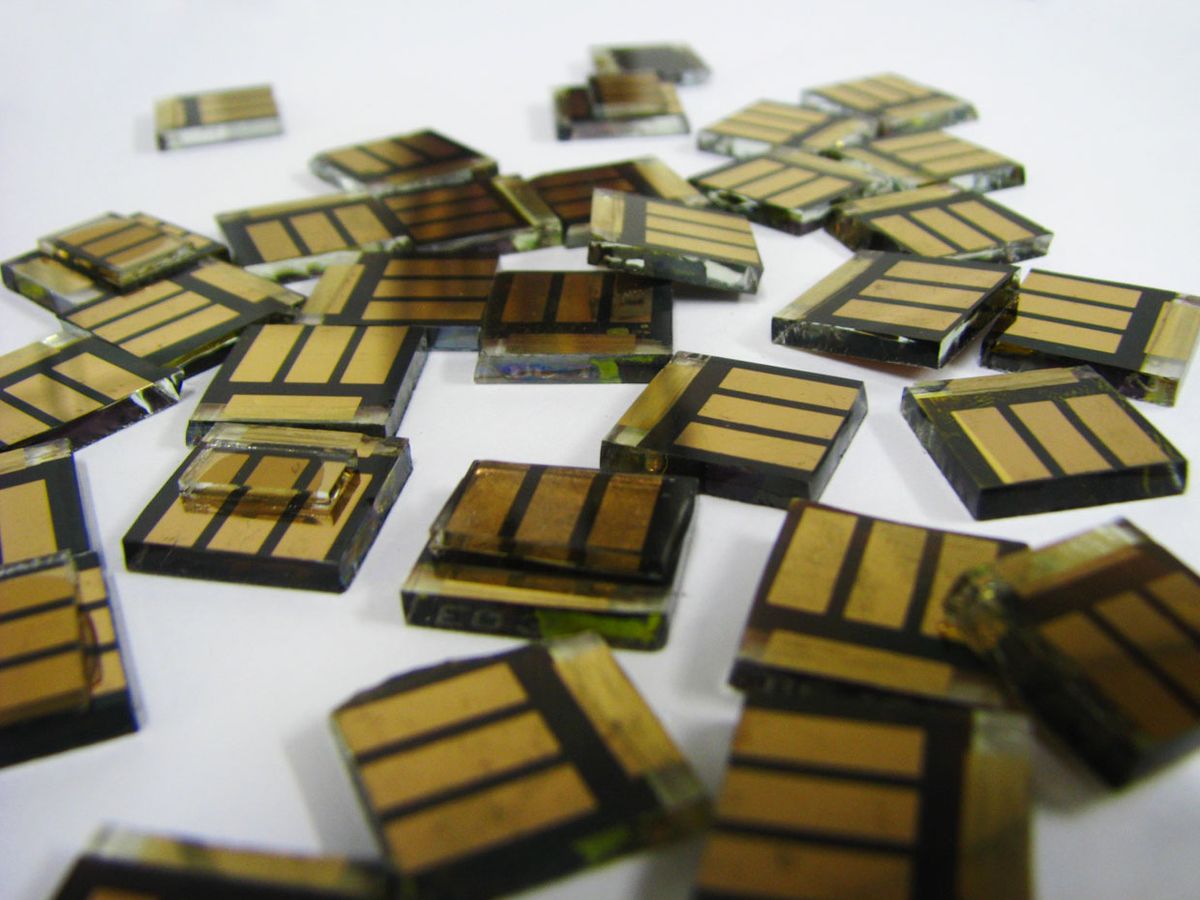

The rapid rise of perovskites is unprecedented in solar photovoltaic research, where efficiencies usually inch upward over decades. And these new materials are poised to break out of the lab: Snaith’s spin-off company, Oxford Photovoltaics, expects to have cells commercially available within four years.

Meanwhile, researchers are convinced that there is still plenty of room for improvement, predicting that perovskite cells will surpass 20 percent efficiency by the end of the year. “It’s very hot, very competitive,” says Mercouri Kanatzidis, a perovskite pioneer at Northwestern University, in Evanston, Ill. “The field has grown by leaps and bounds.”

Solar cell manufacturers face a tricky trade-off between performance and cost. Most commercial solar cells rely on slabs of crystalline silicon that are more than 150 micrometers thick and take a lot of energy to produce. Thin-film solar cells—those containing just a few micrometers of such semiconductors as copper indium gallium selenide (CIGS)—have lower material costs, but they are also less efficient. Cells using crystalline gallium arsenide, on the other hand, can reach 30 percent, but the materials involved are too costly for utility-scale solar power.

Perovskites could resolve this quandary by matching the output of silicon cells at a lower price than that of thin-film CIGS: Their ingredients are cheap bulk chemicals, and the cells can be built using simple, low-cost processing techniques.

Perovskites made their debut in dye-sensitized solar cells. When light is absorbed by a dye in the cell, it injects excited electrons into a semiconductor such as titanium dioxide nanoparticles, which carry the charge away and ultimately generate current. Perovskites made attractive replacements for dyes because they absorb light efficiently over a broad spectrum, but researchers soon realized that they are also excellent charge carriers in their own right.

In 2013, Snaith unveiled a cell using a layer of perovskite without titanium dioxide nanoparticles, simplifying the cell’s architecture and pushing its efficiency above 15 percent.

Since then, Sang Il Seok at the Korean Research Institute of Chemical Technology, in Daejeon, has refined the chemical reaction that forms the perovskite layer to smooth defects out of its structure, which pushed his cells’ efficiency to 17.9 percent. And although Yang declined to discuss the technical details of his 19.3-percent cell, pending publication, other researchers say that removing defects was also crucial to his success. Further gains in performance could come from tweaking perovskites’ chemical compositions to broaden the material’s absorption spectrum. “Progress has been so fast,” says Seok.

However, there are lingering concerns that a widespread use of lead-based cells could pose environmental problems, making investors somewhat wary of the technology. Snaith points out that annual lead emissions from coal combustion are 10 times as much as the amount of lead that would be needed for a 1-terawatt array of perovskite solar cells, but he acknowledges that “it would be better to have completely nontoxic materials.”

In May, Snaith and Kanatzidis independently reported a possible solution: tin perovskites that managed 6 percent efficiencies. Although the tin perovskites are much less stable in air than their lead counterparts, both scientists are convinced that they have potential.

As competition in the lab grows ever more intense, a parallel commercial race is heating up. Oxford Photovoltaics is in the lead for now, but “a lot of other companies are starting to look at this,” says Snaith.

Oxford is working with glass manufacturers to create photovoltaic glazing products. Windows coated with the company’s perovskite have a gray tint and generate electricity with 6 to 8 percent efficiency. “That’s more than adequate to meet builders’ expectations,” says Chris Case, Oxford’s chief technical officer. It costs about 10 percent more than normal glass, and the electricity should pay back the cost of the windows within 10 years. The company expects the perovskite windows to be produced “in volume” by the end of 2017.

Oxford is also working on utility-scale products and investigating whether perovskites could be teamed with conventional silicon solar cells. The materials absorb different wavelengths of light, and perovskites generate a higher voltage than silicon, so using them in tandem would boost the power output of conventional cells.

The company has a development team of 24 people, backed by £7 million in financing. With perovskite efficiencies rising by the month, Oxford is now aiming to raise more money and expand. “It’s not a cottage industry,” says CEO Kevin Arthur. “We are going gangbusters on this.”

This article originally appeared in print as “The Perovskite Revolution.”