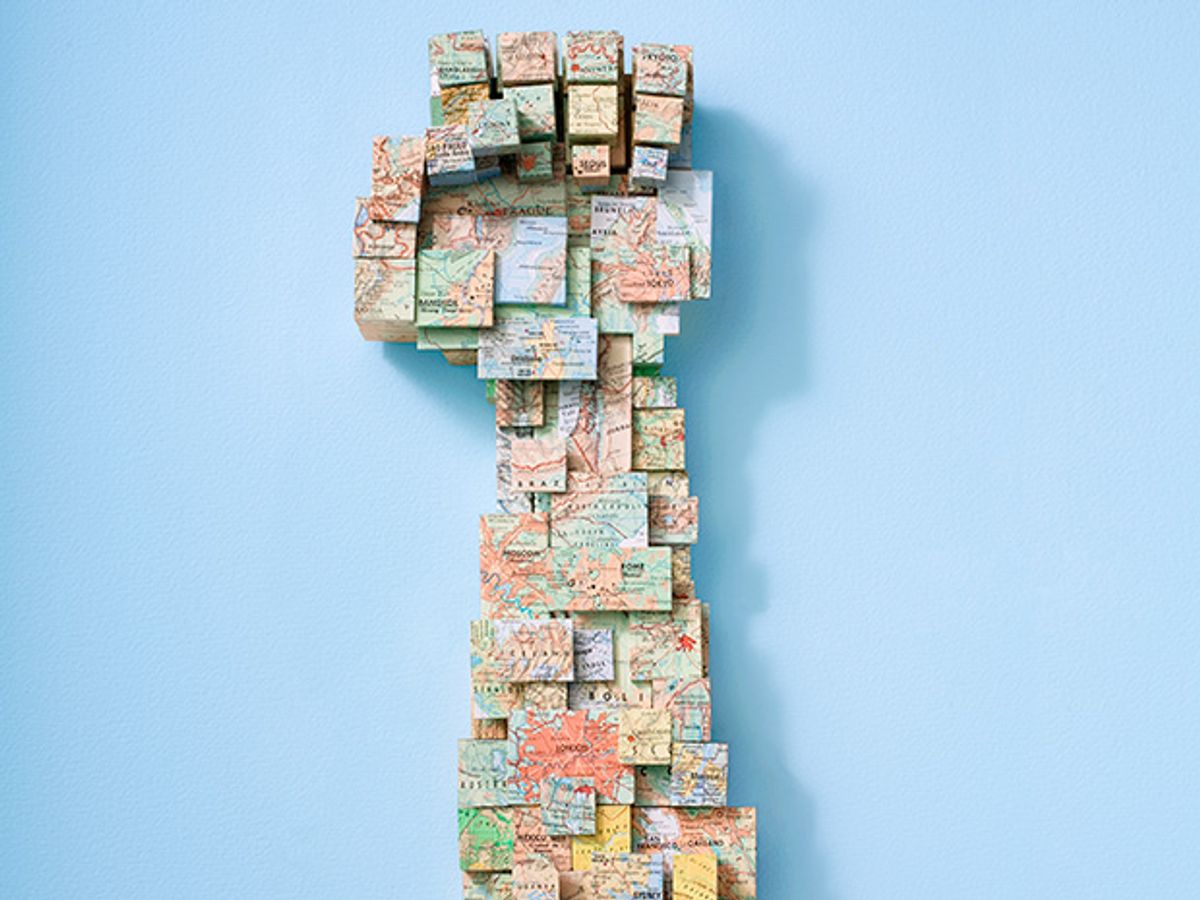

Open Arms

What prosthetic-arm engineering is learning from open source, crowdsourcing, and the video-game industry

On the first day of 2005, I was living inside the Haditha hydroelectric dam on the Euphrates River in Iraq, four and a half months into a deployment as the engineer officer for 1st Battalion, 23rd Marines, in northern Anbar province. The night before, I had rustily fingerpicked my way through a bluegrass song on the guitar in the New Year’s Eve talent show. I went to bed looking forward to an easy day, a welcome change. I’d been on a long patrol over Christmas—sleeping little, getting shot at. In the morning, I made some of the Starbucks coffee my wife had been sending in her care packages, wrote an e-mail to a friend back home, and headed out to a planning meeting with another officer.

Our meeting was cut short around 9 a.m. when a report came in that one of his riverine boat patrols had been attacked from the shore. I joined the group that went out to respond. We got off the boat and started patrolling the shore on foot, but all we found was evidence of the previous firefight. The Marines began to secure the area.

I was on the ground before I was even aware of the sound of an explosion. The blast from the improvised explosive device—explosives and scrap metal hidden in an olive oil can—broke my M4 carbine in two and nearly severed my right arm. Before the Blackhawk helicopter took me away, I remember telling the executive officer, “I guess my guitar-playing days are over.”

I stayed conscious until we reached the U.S. Navy Alpha Surgical Company at Al Asad Airbase. Then I was anesthetized and sent to the operating room, where I joined the hundreds of amputees who have lost limbs in the two wars we are currently waging.

Improvised explosive devices (IEDs) like the one that got me had become, by mid-2004, our enemies’ weapon of choice, and we had spent a lot of time preparing for the threat. We were all to some extent prepared for the possibility of death, but I hadn’t given much thought to how my life might change if an IED took one of my limbs. Ever since the first few amputees returned from Afghanistan in 2001, they have been the very public face of modern warfare as it is waged on the ground—a little different from the sterile video output of a laser-guided bomb or unmanned drone. The media coverage often emphasizes the medical care that saves their lives, and the advanced prosthetics they wear, with phrases like bionic arms and thought control.

Lying in a hospital bed in Landstuhl, Germany, I only knew that I had survived and that a young Marine named Brian Parello had not. The doctors had saved my right elbow and part of my forearm. I talked to my wife on the phone. I got a Whopper from the hospital’s Burger King. On the way back to the United States, in a morphine haze, I took pictures as we flew over Iceland. I made my first, totally unintelligible attempts to write with my left hand. I already felt worlds away from Anbar province, and I immediately began to feel guilty about the early ticket home, despite its price.

I arrived in the United States on January 5 and was home a week later on convalescent leave. Before I deployed, I was a biomedical engineering graduate student at Duke University, in Durham, N.C., so I did what any engineer would do with the time: I began scouring the Internet for articles on prosthetic technology, trying to envision what my future would look like. My doctor told me I would have to go through a few more surgeries, and once my incisions had healed I would get a state-of-the-art myoelectric arm.

Myoelectric armshave joints powered by electric motors. They are controlled by electrical signals on the surface of the skin, which are produced by the remaining muscles in the arm. According to a 2005 article, the latest and greatest myoelectric prosthetics allowed a wearer to move the limb just by thinking about it. Many articles have anticipated robotic arms that function as well as or better than their human analogues—letting an amputee shave, hold a knife or fork, button a shirt, or turn an ignition key.

I went to see Glen Hostetter, a prosthetist at Duke. I was telling him how excited I was about the arm I would get at Walter Reed Medical Center when he stopped me. “Have you ever seen a myoelectric hand?” he asked quietly.

I had never seen a real one up close. He dug around the back of his office and brought back a demonstration model of a child’s myoelectric hand. All I could say was, “That’s it?”

Instead of the lifelike motion of individual fingers I had expected, I was looking at a rigid, hand-shaped electric clamp. The creepy “flesh tone” vinyl glove encasing it seemed to be designed more to make other people feel better than to restore function. The arm I eventually got at Walter Reed wasn’t much better. The socket offered a limited range of motion. The beautiful cover, painted by an artist, was too fragile for everyday use. The hand couldn’t even turn a doorknob, and it was useless for what prosthetists clinically call the “activities of daily living”—the same activities the popular science coverage had talked about. It was not what I expected it to be, nothing like what I’d been promised by the media, and definitely not what I wanted.

The chasm between what people think is out there and what is actually available to an amputee has existed for years. The hype isn’t limited to the popular press: Scientific research and even scientific literature repeat these claims. The first myoelectric prosthetic arm was demonstrated in 1955. That benchtop presentation included a powered hook that looks remarkably like one I got from Walter Reed. In 1965, a New York Times headline proclaimed “New Process Will Help Amputee to Control Limb With Thought.” In 2007, a Popular Science article described an early prototype robotic hand as ”mind controlled” and “dexterous enough to play the piano.” There was even a video of the hand playing “Frère Jacques.” The headlines have stayed the same, but as I discovered, so has the technology. These prosthetic “concept cars”—even the ones that live up to their claims—have historically had little effect on what most arm amputees actually wear.

Let me be clear: No expense has been spared on providing military arm amputees with the most cutting-edge technology available for replacing their limbs. Amputees at Walter Reed get the works—myoelectric and body-powered prosthetic arms with any attachments we might want, sports and other task-specific arms, cosmetic arms painted with the tattoos we used to have, you name it. In 2006, the Veteran’s Administration spent US $1.1 million on prosthetic devices and services. It’s the best insurance and the best care in the world, but that doesn’t change what there is to buy or what it can do.

The body-powered prosthetic split hook I chose instead of the myo arm has been characterized by some as little more than a rubber band and a stick. But the surprisingly useful mechanical design has endured for close to a century. It has been improved incrementally since 1912, when it was patented by D.W. Dorrance, who lost his arm to an industrial accident. Body-powered prosthetics have cable controls that you move by shrugging and tensing your shoulders, an action that opens and closes a simple hook or hand appendage. After trying everything else, I opted to wear this arm exclusively.

The kind I wear, made by Hosmer Dorrance Corp., is indistinguishable from those worn by amputees after World War II, except in materials: silicones and plastics in the socket, carbon fiber instead of wood or fiberglass in the frame, titanium instead of steel in the hook, Spectra (a type of strong, lightweight synthetic fiber) instead of steel cable for control. Despite two corporate acquisitions, Dorrance’s name remains stamped on every hook the company makes.

The hook retains the rubber grip and “cigarette notch” added by the Army in the 1950s. In fact, you’ll find most of the parts of my arm described in a January 1954 article by M.J. Fletcher about the prosthetic state of the art titled “The Upper-Extremity Prosthetics Armamentarium” in the journal Artificial Limbs. The same parts and pictures appear in the current Hosmer Dorrance online catalog.

Imagine this pace of development for other everyday products. We would make our calls on big black rotary-dial Ma Bell telephones (lightweight carbon fiber body!), add up to 28 columns of figures using the punch cards of the IBM 650 (improved 56-column design!), and we could go zero to 60 in a Corvette in almost 10 seconds (updated color selection!). If this seems preposterous for other industries, why is it the unfortunate reality of the prosthetic arm industry? Where’s Moore’s Law for prosthetic arms?

The problem is the size of the market for prosthetic arms, which is just too small to provide any real incentives for innovation. In the modern conflicts in Iraq and Afghanistan, 862 U.S. troops have become amputees, of which only 186 have lost arms as of February 2009. The total arm amputee population in the United States is under 100 000. Anyone who approached a venture capitalist with a business plan with significant technical challenges and only tens of thousands of potential customers would be laughed out of the room. The government is, and will remain, the only game in town as far as research and development in prosthetic arms.

The same year I lost my arm, the Defense Advanced Research Projects Agency (DARPA) began the Revolutionizing Prosthetics program, whose costs now total nearly $100 million. The program was split into two parts: The 2007 project, headed by Dean Kamen’s New Hampshire–based Deka Research and Development Corp., was given a two-year deadline to make an advanced prosthetic arm with the world’s best existing technologies.

The 2009 program is spearheaded by Johns Hopkins University’s Applied Physics Laboratory, in Laurel, Md. APL’s goal is to create prosthetics that would, as the hype had it, be ”thought controlled.” But the team wanted more than control for amputees; they also wanted to restore the ability to feel heat, cold, pressure, and surface texture. I found out about the program at Walter Reed when I was first being fitted for prosthetics, and I was anxious to get on board. Now I’m one of over 300 engineers at over 30 institutions worldwide working on the APL project. At Duke, I’m helping with suspension (attaching the arm to the body), grasping control, and system design.

Because of its ambitious goals and compressed schedule, Revolutionizing Prosthetics has often been compared to the Manhattan Project. But let me stress that unlike the Manhattan Project, the entire Revolutionizing Prosthetics program budget could fit inside the cost of a single Joint Strike Fighter—with room to spare.

It’s important to talk about the money because, given the scale of the funding and the task, what both DARPA projects have achieved so far is nothing short of incredible. But it’s far short of the miracles that have been reported in the press, which have exceeded even the ambitious goals of the entire program.

Remember the Popular Science article about the mind-controlled hand that was dexterous enough to play the piano? That article conflated two prototype hands developed by the APL team: the Extrinsic Prototype 2 Hand and the Intrinsic Prototype 2 Hand. The former is powered by one of the most fiendishly complex mechanical devices I’ve ever seen—it was an early exploration into a possible strategy for controlling individual fingers. The Intrinsic hand was physically capable of all the individual movements necessary to play the piano, but it could not be controlled by a person in real time. There was no muscle twitch or electrical signal being decoded by signal-processing algorithms in real time. The hand was preprogrammed, like a player piano. Dexterous manipulation—the cooperation of two hands and 10 fingers to achieve a complex control goal—is the holy grail of prosthetic hand function, but we’re not there yet. The difference between grasp and dexterity is the difference between picking up a Rubik’s Cube and solving it.

At this point, no one is even trying to make a hand that will let a user win a Rubik’s Cube competition or play the piano. It’s just not yet possible to perform tasks that require such dexterity in real time.

Though both DARPA projects come very close to living up to the hype that surrounds them, they must become real products in order to help anyone. We need to push the arm that last mile to the consumer. And that’s where we run into the biggest challenge. The most important thing we can do right now to push arm prosthetics into the 21st century is to work around the tiny market size and break down the barriers to innovation.

As I discovered the difference between the science fiction and the reality of prosthetic arms, I tried to come up with a solution. I came up with some ideas for simple improvements to the body-powered arms I prefer, but I quickly realized that there wasn’t much of a business case for commercialization. So some friends and I started the Open Prosthetics Project in Durham as an online clearinghouse for sharing prosthetic arm designs. The project attacks the most obvious barrier to innovation by giving people a forum in which to share their ideas. We want to start a dialogue among all the stakeholders. We want users and technicians to improve and tweak the technologies they use instead of being stuck with whatever one-size-fits-most device they get (for example, there is a section on our Web site called ”Pimp My Arm”). A technically inclined amputee or technician can download our computer-aided design (CAD) files, modify them, and send them to a machinist.

We hoped that we could disrupt the stagnant commercial market, as Linux has for software. We thought openness was the solution. But it turned out not to be that easy.

One major lesson from the Open Prosthetics Project is that sharing a design isn’t necessarily enough. Consider the story of the Trautman hook. Edgar Kulcas, a longtime Trautman user, needed a new hook, but it had long since gone out of production. So we improved the old design and made it available on the Internet. You’d think that would mean someone like Kulcas could now simply download the design and have it made by a local machinist. But that’s not what happened.

We had the hook made by a rapid prototyper and sent it, along with several others, to prosthetists whose patients, like Kulcas, were eager for replacements. They were “well pleased,” as Mr. Kulcas put it, and I’m still getting e-mails requesting these hooks. The problem is that no manufacturer is going to jump up and start making that design again. The long-expired 1925 patent doesn’t obviate dubious and expensive trademark claims. Beyond that, many people are nervous about the prospect of manufacturing an FDA-regulated device.

And the future doesn’t look much better. Otto Bock HealthCare, one of the largest prosthetics manufacturers in the world, is also the transition partner for the four-year project. That means the company, which is based in Germany, will turn APL’s Revolutionizing Prosthetics research into next-generation commercial prosthetics. But Otto Bock is not waiting for the close of the project to use the components the company designed for the first APL prototype arm. Otto Bock plans to use these same components in its next-generation “intelligent arm,” which could be on the market as early as 2010. That itself would not be a problem, but in 2008 the company announced that the arm would use a proprietary and encrypted digital communication standard, called the Axon bus, for its new systems. This will create a tectonic shift in the industry. Previously, all companies—be they 800-pound gorillas like Otto Bock or smaller, niche providers like Liberating Technologies, which makes the Boston elbow—used the same mechanical and electrical components originally created by Otto Bock. All the parts spoke the same language. But now the next generation of commercial prosthetics will communicate in a code no one else will be able to crack. Marginal competitors like Liberating Technologies—along with Motion Control, which makes the Utah arm, and Touch Bionics, which makes the iHand—make individual parts that plug into the most widely used systems, the only real spot of innovation in a static landscape. If these companies can no longer make these individual parts without creating an entirely new arm to go with them, they won’t survive. That translates into yet another narrowing of options available to amputees.

Otto Bock’s decision is not a unique development. Deka Research has declared that it has no intention of participating in any open standard for communication. However, the wrist rotator on Deka’s arm remains too large for below-elbow amputees like me to use. Addressing the specific needs of below-elbow amputees was not a DARPA requirement, but most arm amputations are below the elbow. The ability to swap different manufacturers’ components would have solved that problem.

It’s worth looking at this in terms of the current economic stimulus or recovery packages. We’re spending a lot of government money doing something that industry has failed to do, so we need to ensure that we’re getting our money’s worth. Col. Geoffrey Ling, the program manager on the Revolutionizing Prosthetics project, made it clear from the start that this wouldn’t be just another science project—this project would have real benefits in the real world.

So in the middle of the four-year project, the APL team decided to open up the framework of its project. The steps it is taking are virtually unheard of: First, APL is making its virtual environment open source. The APL team has created a virtual integration environment, a training simulation in which signal processing and control techniques can be tested and an amputee can watch him- or herself drive a virtual arm. Second, the team also plans to publish an open control communication architecture for the limb. Finally, APL intends to publish the mechanical interfaces for each physical component, such as the wrist rotator or the finger joints. (Opening the architecture for mechanical and electrical interfaces, by the way, should not be confused with open-source software; adhering to a common interface doesn’t require a manufacturer to publish trade secrets about how its improvements were made.)

These innovations will give any company—or individual—access to the physical specifications of the APL arm as well as parts of the control software. They’ll even have a virtual environment in which to test their adaptations.

The best way to really move prosthetics research forward is to hitch a ride on a real market. If we can find an application for a myoelectric human interface in the $32 billion worldwide video-game market, for example, we can tap into a massive reserve of people who might not otherwise get involved in the effort. Any tool they develop could be repurposed for prosthetics, allowing that small market to benefit from the economies of scale that are usually available only to much larger ones. The MyOpen project on the Open Prosthetics site is working on ways to create a product that can serve both a niche and a mass market. MyOpen, an open-hardware signal-processing board that will be compatible with APL’s arm, will also serve as a universal controller for video games. We want creative people to get their hands on this device and push it to the limits. We want this device to enhance the experience of playing video games, and in doing so, push prosthetics innovation into the 21st century.

Another possible application is robotics. Prosthetic arms aren’t the only devices that require centrally controlled powered joints. The compact and powerful motors designed for the APL project—less than a centimeter in diameter and capable of producing 8 watts—could be useful in bomb disposal, hazardous waste inspection, and home-service or hobby robotics, for example. If the communication standards developed for the DARPA project were adopted by one of these industries, then terminal devices like individual joints and hands could see much wider use. In turn, the devices would benefit from much more R&D.

Dean Kamen is famous for founding the FIRST (For Inspiration and Recognition of Science and Technology) mentoring program, which inspires young people to get involved in science and engineering. An open architecture for the Deka arm could be the basis for a FIRST competition with dexterous tasks—think DARPA Grand Challenge or a piano sight-reading competition. I’ve served as a mentor to FIRST Robotics Team 900 at the North Carolina School of Science and Math. Based on my experience with these students, I think they would relish the opportunity to work on a problem that significantly affects lives.

The greatest revolution of all may be apparent only after the frenzy of prosthetics research spending has evaporated. The design evolution for which DARPA is laying the groundwork could come from any quarter, inside or outside the prosthetics industry. And who knows—someone might even make money doing it.

About the Author

JONATHAN KUNIHOLM is a veteran of the Iraq war, an engineering researcher at Duke University, and an amputee. You might remember him from the cover photo of our January Winners & Losers issue, in which he wears a prototype of the (winning) Revolutionizing Prosthetics arm.