Nissan’s All-Electric Leaf Doesn’t Stint on Performance

The Nissan Leaf is limited only by the range of its battery’s charge

This article is part of an IEEE Spectrum special report: Top 10 Tech Cars of 2010.

First a left turn, then a speedy stretch, and then a gentle, swishing zigzag through a parade of orange cones. The drive is nothing to report on, and that’s the story, because I’m running not on gas but on electrons.

I’m in an old train-station parking lot on a wintry morning in Vancouver, and I’m behind the wheel of one of this year’s most eagerly anticipated cars. Well, sort of. The car is actually what engineers call a test mule: It’s got the guts of a Leaf, Nissan’s first pure-electric vehicle, but the body of a Versa sedan, Nissan’s plain-Jane budgetmobile. Due out in parts of Japan, the United States, and Europe late this year, the Leaf will be the world’s first affordable, mass-market, all-electric car, Nissan says. And it’ll also be one of the first electric vehicles from a mainstream maker with state-of-the-art lithium-ion batteries. Nissan says it will have a range of 160 kilometers (100 miles) on a charge and will deliver a respectable 280 newton meters (207 foot-pounds) of torque.

Under the hood, the Leaf’s 80-kilowatt synchronous AC motor drives the wheels directly, without a gearbox, delivering maximum torque starting at zero revolutions per minute. Though Nissan declines to specify the acceleration, it claims the Leaf tops out at 145 kilometers per hour (90 miles per hour).

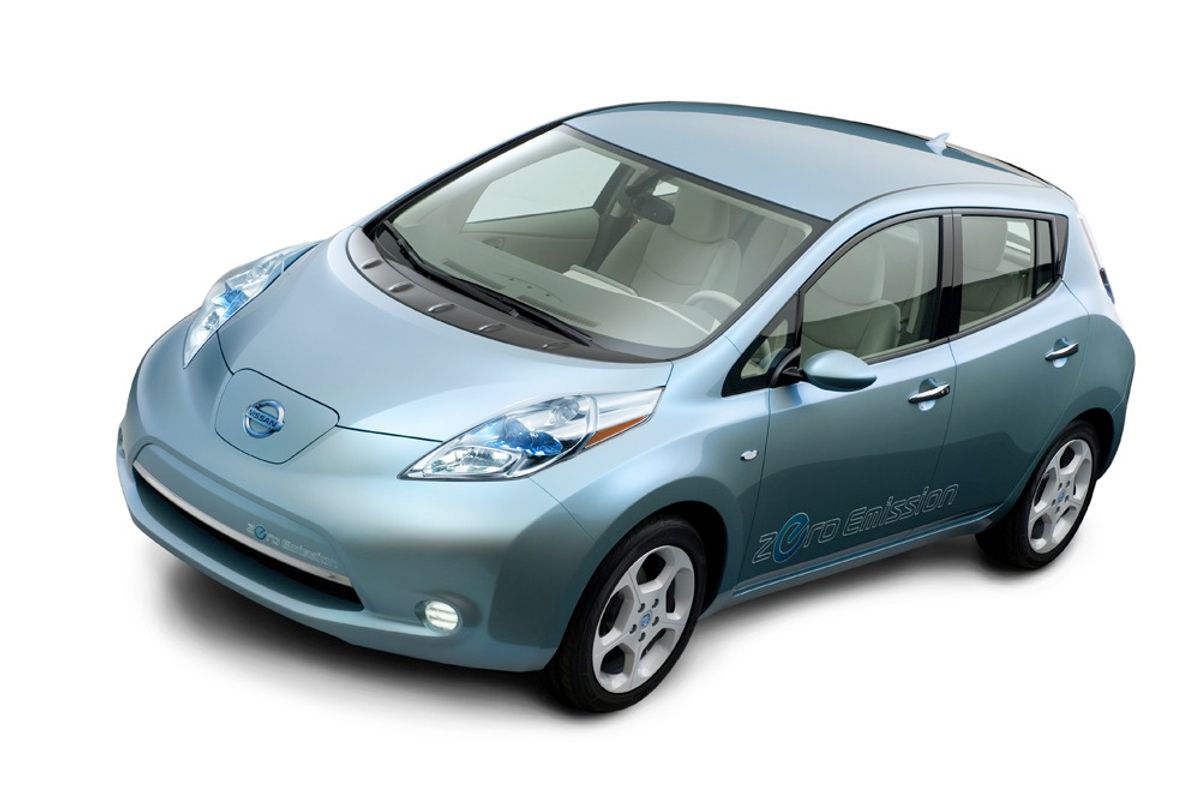

In Vancouver, Nissan also provided a look-but-don’t-touch model of the real Leaf. It looks a lot like a Toyota Prius, with a sloped front and a boxier back end. The interior has a futuristic feel, with a glowing blue console and, in place of a shifter, a mushroom-shaped controller (video gamers rejoice!). As a bonus, the car will be able to tell you where nearby charging stations are. It’ll even tell your smartphone when it’s finished juicing up.

But it’s the Leaf’s zero-emissions potential that has some of the attendees in Vancouver salivating. “This will take my carbon footprint almost to zero,” one crows. Another declares, “If you have two cars, this should be one of them.”

The Leaf is a big gamble for Nissan. Unlike other major automakers, Nissan has bypassed hybrids in favor of pure-electric cars. President and CEO Carlos Ghosn’s plan is to move fast to capture a sizable share of the market for pure EVs, which Nissan expects to account for 10 percent of global car sales by 2020.

Nissan will say only that the Leaf will cost about as much as a conventional gasoline-powered five-person sedan, such as its Sentra or Altima. That puts the car somewhere between US $15 000 and $25 000, although the company hasn’t made clear whether that price range will include the full cost of the battery. Nissan also says there won’t be a “green premium”: Average drivers will spend much less on electricity than they would spend on gasoline in a comparable, conventional car.

And it’s smooth. In a Prius, there’s a slight thump when the engine kicks in. Not so in the Leaf, because there’s no engine. There’s just a satisfying punch when you stomp on the accelerator.

The car’s biggest novelty—the battery—lies beneath the back seat. Conventional lithium-ion packs consist of cylindrical cells encased side by side, creating air pockets that trap heat and require auxiliary cooling, which saps efficiency.

Nissan’s new batteries consist instead of sheets of lithium manganese and graphite, stacked in waferlike cells, each about the size of a manila envelope. Four of these cells get packed into a box the size of a textbook. Nissan managed to fit 48 such boxes beneath the seat and under the floor. Simple airflow is enough to cool them. The battery can deliver 90 kW of power and has an energy capacity of 24 kWh, about twice that of Nissan’s previous lithium-ion batteries of the same size. And Nissan’s already working on a version with a lithium nickel manganese cobalt oxide cathode, which might double again the battery’s capacity.

A big pothole, though, may lie ahead for Nissan. It doesn’t matter how good the batteries are if you can’t easily recharge them. As with other electric cars, the biggest challenge for the Leaf is the charging infrastructure. “If it’s not easy for customers, it’s not going to work,” acknowledges Nissan Canada’s marketing director, Mark McDade.

So the company is working hard to make it easy. Nissan recently announced that if you buy a Leaf, it will have a contractor install a charging station in your garage before the car arrives. With a 220-volt charger, you can replenish a fully depleted battery in 8 hours. Nissan is also prodding governments and electric utilities to deploy public charging stations, which could charge the battery up to 80 percent in just under 30 minutes to support long-distance driving.

Here in Vancouver, with snow threatening to fall any minute, I return to the test track one last time. I want to check a feature I’d forgotten to pay attention to: noise—or the lack thereof. All I can hear is a cool electric whine of the motor as I accelerate. When I stop, it’s totally quiet. So one last bit of advice for future Leaf owners: After parking the car, double-check that you’ve hit the “off” button before walking away. You don’t want those precious electrons to trickle out.

This article originally appeared in print as “The experience electrifies—until the battery dies.”

To Probe Further

Check out the rest of the Top 10 Tech Cars of 2010.