As much as we love Canada, our northern neighbors don't exactly have a huge space program going on up there, probably because you can't launch rockets on maple syrup.

I kid, of course. You can totally do that.

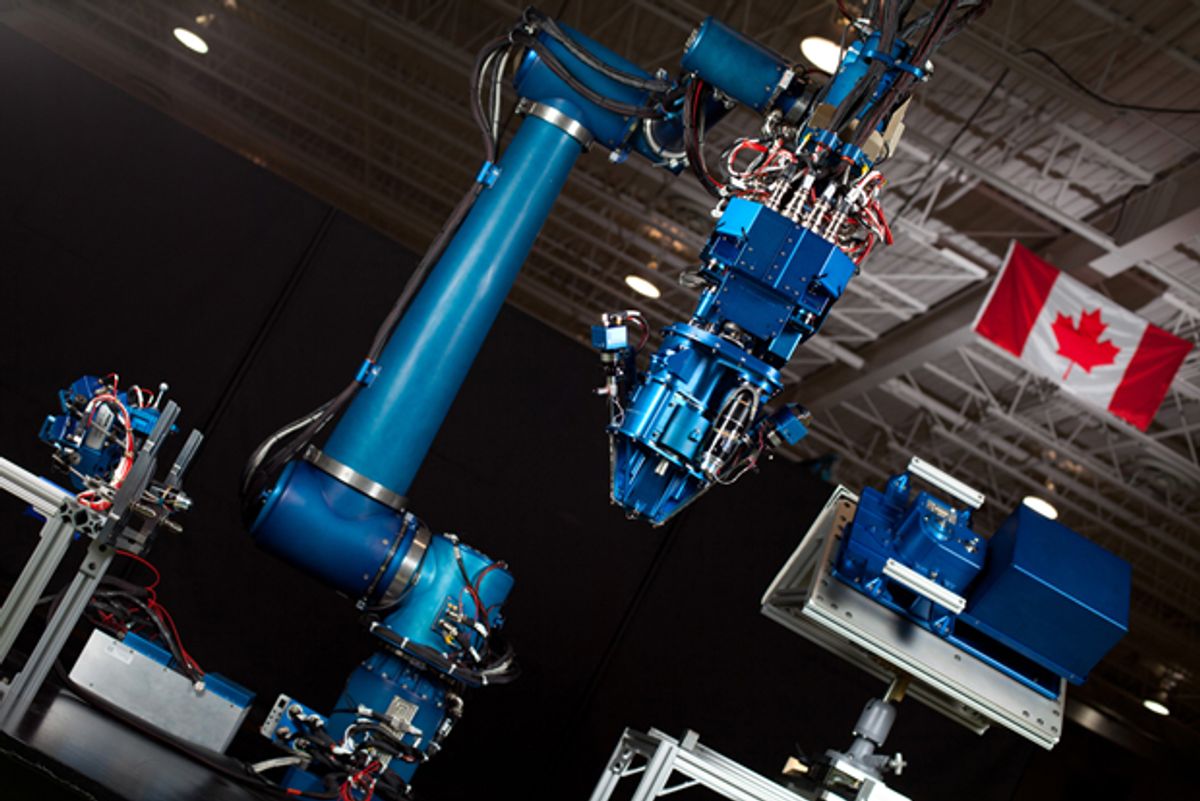

Anyway, the Canadian Space Agency is probably best known for two things: Chris Hadfield, and the Canadarm and Canadarm2. These giant robotic space-arms have been flying on the space shuttle since 1981, and the latest currently serves as Dextre's lower body on the ISS. As always, we're wondering what the next generation of Canadarm is going to be like, so we were excited to see this video from the CSA showcasing their next generation Canadarm project: the "Next-Generation Canadarm Project." Mind = blown.

There are two different arms that are part of the project: the little guy in the picture at the top of this article who has a 3 meter reach, and his big brother, with a 15-meter reach:

Despite the size, the folding and telescoping arms can stuff themselves into just five cubic meters, which is approximately the volume of a space minivan. And since more robots = better, you can stick the little arm on the big arm to make what I guess would have to be a Canadarmarm.

As the CSA quite rightly points out, there's a huge amount of space junk flying around up there, and launching satellites is expensive and (eventually) wasteful. With some friendly Canadian robots in orbit to repair and refuel and upgrade existing systems, we can keep that space junk flying just as long as we need it to.

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.