A new low-temperature method for making perovskite solar cells paves the way for high-efficiency, colorful, see-through photovoltaic films that could be laminated on windows or plastered on walls.

Perovskite solar cells have become darlings of the photovoltaic world in the past five years. Their efficiencies in that time have soared from a meager 4% to over 20%, quickly catching up to silicon’s 25%.

Another appeal of these solar cells is that the light-absorbing perovskite layers are easy and much cheaper to make than silicon wafers. Mix some precursor chemical solutions, coat it on a substrate and then heat it to evaporate the solvent, and you have yourself a film of perovskite crystals.

But that heat can cause problems. The crystals often form unevenly during heat-treatment, which leaves tiny holes in the film, says Nitin Padture, a professor of engineering at Brown University. The typical temperatures of 100–150°C that are used to make the crystals also limits them from being made on plastic surfaces, which would melt at those temperatures.

So Padture and his colleagues first made a perovskite precursor solution in a solvent called NMP that is used in the petrochemical and plastics industries. They coated the solution on a substrate. And then, instead of heating, they used a second, different solvent to wash the surface. This second solvent attaches to the NMP and whisks it away.

The researchers were able to make smooth, high-quality crystalline films and could precisely control the film’s thickness across large areas. Initial tests at the US National Renewable Energy Laboratory shows that the films have light-to-electricity conversion efficiency more than 15%.

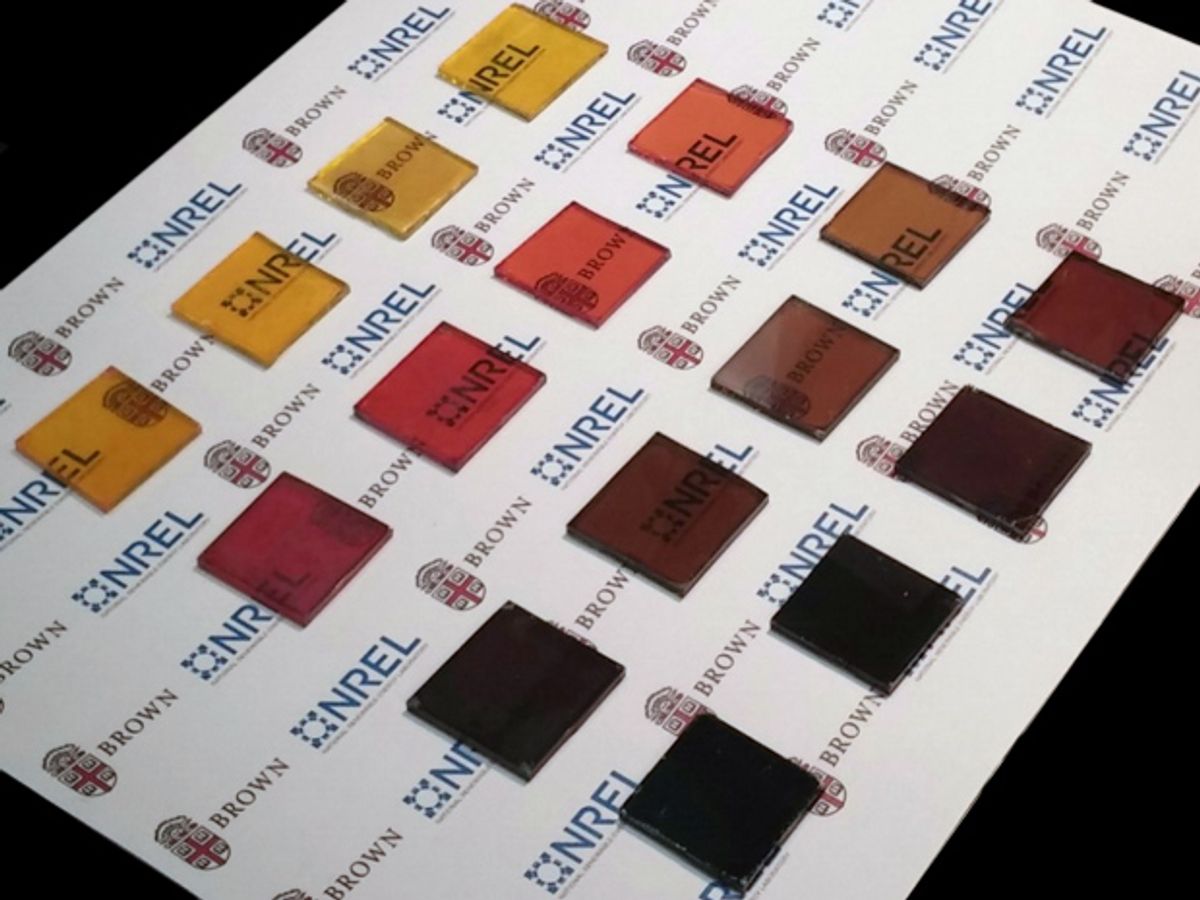

Standard perovskite films are around 300nm thick, and are typically black and opaque. By comparison, the new method gave films as thin as 20 nanometers that were nearly transparent. Tweaking the precursor chemicals led to films of different colors.

The process is also much faster. It took two minutes as opposed to an hour or more for heat-treating, which makes it more suitable for mass production, the researchers say.

"We think this could be a significant step toward a variety of commercially available perovskite cell products," Padture said in a press release. The researchers presented their findings in the Royal Society of Chemistry’s Journal of Materials Chemistry A.

Prachi Patel is a freelance journalist based in Pittsburgh. She writes about energy, biotechnology, materials science, nanotechnology, and computing.