Many of us are ready to throw our collection of tangled charging cables in the garbage and replace it with technology that relies on wireless power transfer. So far, though, wireless power transfer (WPT) systems have mostly been limited to supplying power to a single load, such as an individual phone. The few systems that support multiple loads do not currently allow for independent control over each one, making it a challenge to simultaneously charge devices that require different amounts of power.

This may change in the near future, thanks to a new design developed by Chris Mi at San Diego State University and his colleagues that allows for independent control over 10 loads. Their work is described in a recent study in IEEE Transactions on Power Electronics.

Supplying different amounts of power to individual devices could be useful in a number of scenarios, such as for charging stations that serve various types of vehicles (including electric cars, bicycles, and scooters). But it has been hard to customize the delivery of power in this way due to a fundamental constraint of conventional circuits: If the resistance for one load changes, that changes the power passing through every other load connected to the same WPT system.

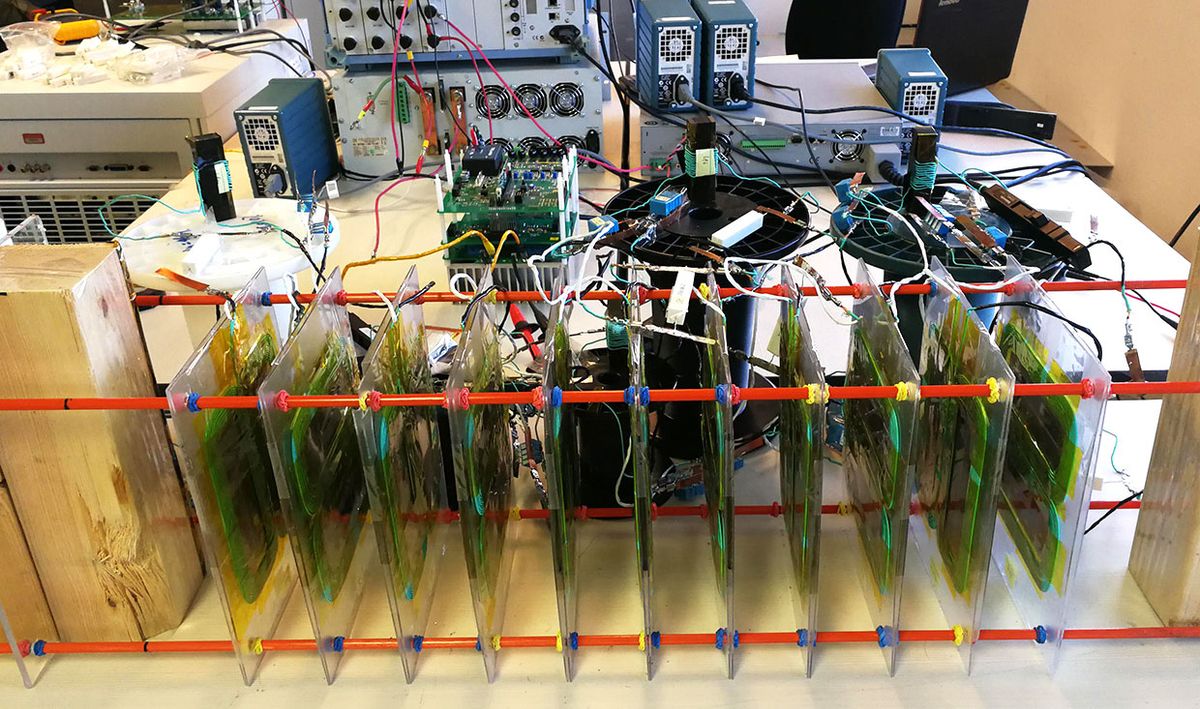

To address this issue, Mi and his team developed a novel WPT system. They started with a typical near-field WPT system that uses magnetic induction to transfer power between a sequence of repeater units. These units are unique, however, in the sense that they harbor two repeater coils perpendicular to one another. The first coil is responsible for receiving power from the previous unit, while the second coil supplies wireless power directly to the load, and transfers power to the next unit in line. “Thus, multiple loads can be powered at the same time with isolation between each other,” explains Mi.

Another key factor that makes this system successful is the strategic layout of ferrite plates, which are used to boost magnetic induction between units. Here, the ferrite plates are laid out in such a way that they increase the magnetic coupling between adjacent units—while sparing unwanted coupling between the perpendicular coils inside each unit. This enhances the flow of power between units and to each load.

Tests of their system reveal that, in terms of efficiency, it outperforms two other existing multiple load systems. “The maximum efficiency of the designed system can reach 83.9 percent, which is very high considering there are a total of 10 loads,” says Mi. One other system compared in this study can reach roughly 90 percent efficiency, but it only supports three loads.

In their current experimental setup, the units were spaced 6 centimeters apart, but Mi says his team is working on increasing that distance to up to 50 cm. As well, the system is intended to deliver power to receiving circuits, which have not yet been designed. In this study, resistors were used as a load.

Mi says, “In the future, we will design the receiving circuit to transform the received power to constant DC output for the driver circuit and use the proposed technology in real driver circuits, which will [bring] our research one step closer to industrial applications.”

Michelle Hampson is a freelance writer based in Halifax. She frequently contributes to Spectrum's Journal Watch coverage, which highlights newsworthy studies published in IEEE journals.