Perhaps the latest news on the pages of IEEE Spectrum that details how two companies are printing batteries and ultracapacitors is the most promising to date.

The spectrum article reports on a printed solid-state lithium battery developed by Planar Energy Devices that manages to replace the liquid electrolyte typically found in lithium-ion batteries with a ceramic electrolyte. The results are that it performs much better than traditional li-ion batteries, achieving 400 watt-hours of energy per kilogram and can last for tens of thousands recharge cycles.

While this is at least a factor of two better than traditional batteries, for electrical vehicles it still falls short of the 1000Wh/kg target that was suggested by Energy Secretary Steven Chu to be what is needed for a power source to replace fossil fuels in automobiles.But if Tesla can make a buck selling sports cars with 6,831 lithium-ion batteries that weigh all together about 1500 lbs, surely a car company could do better with the lighter, cheaper to produce, greater energy density and longer life cycle of the batteries being offered by Planar.

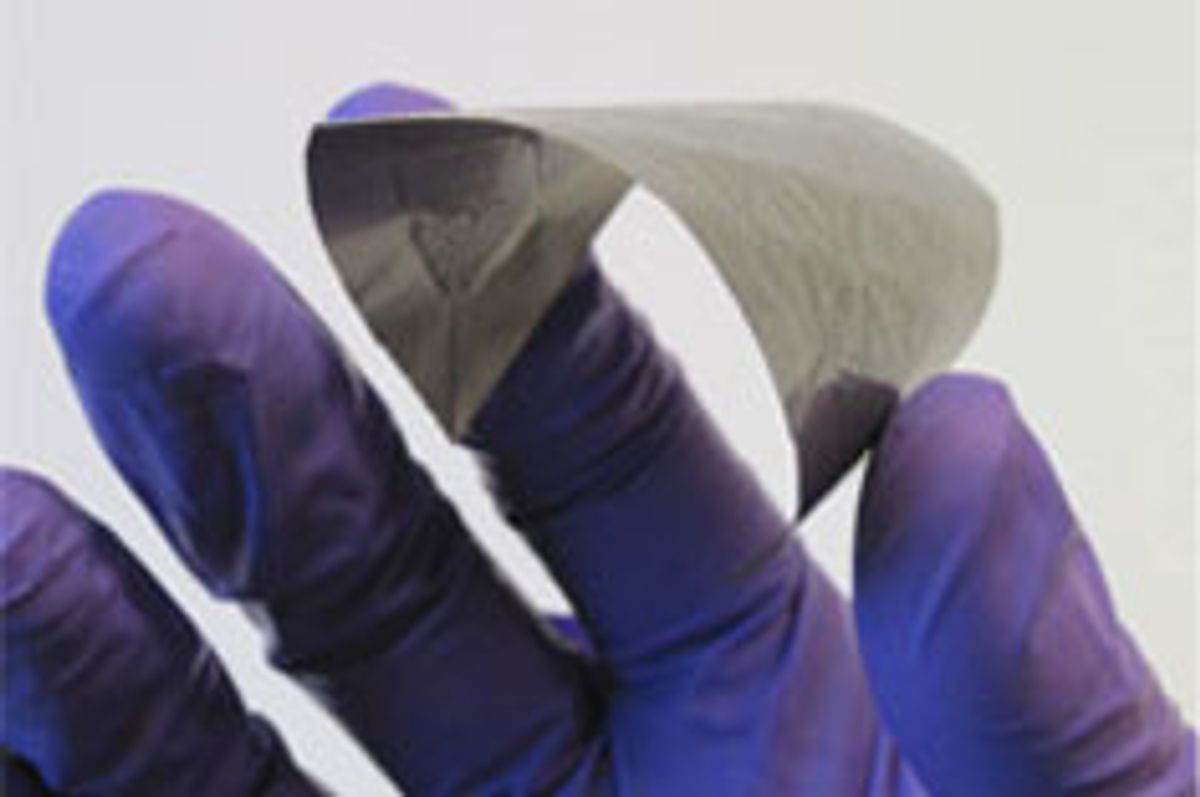

The other company highlighted in the article is Paper Battery, which produces an ultracapacitor that uses a nanostructured paper as the separator between the electrodes in the ultraccapcitor. It looks as though initial applications will be in the areas of a medical diagnostic devices and thin film solar panels

If these two companies are any indication, we should expect things to start heating up in the printed battery and ultracapacitor space fairly soon.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.