Remember how Leonard McCoy performed surgery in Star Trek? He would wave a device over the patient. The outer layers of the skin didn't need not be cut, even when operating on internal organs, and the precision of 23rd century instrument reached down to the level of individual cells.

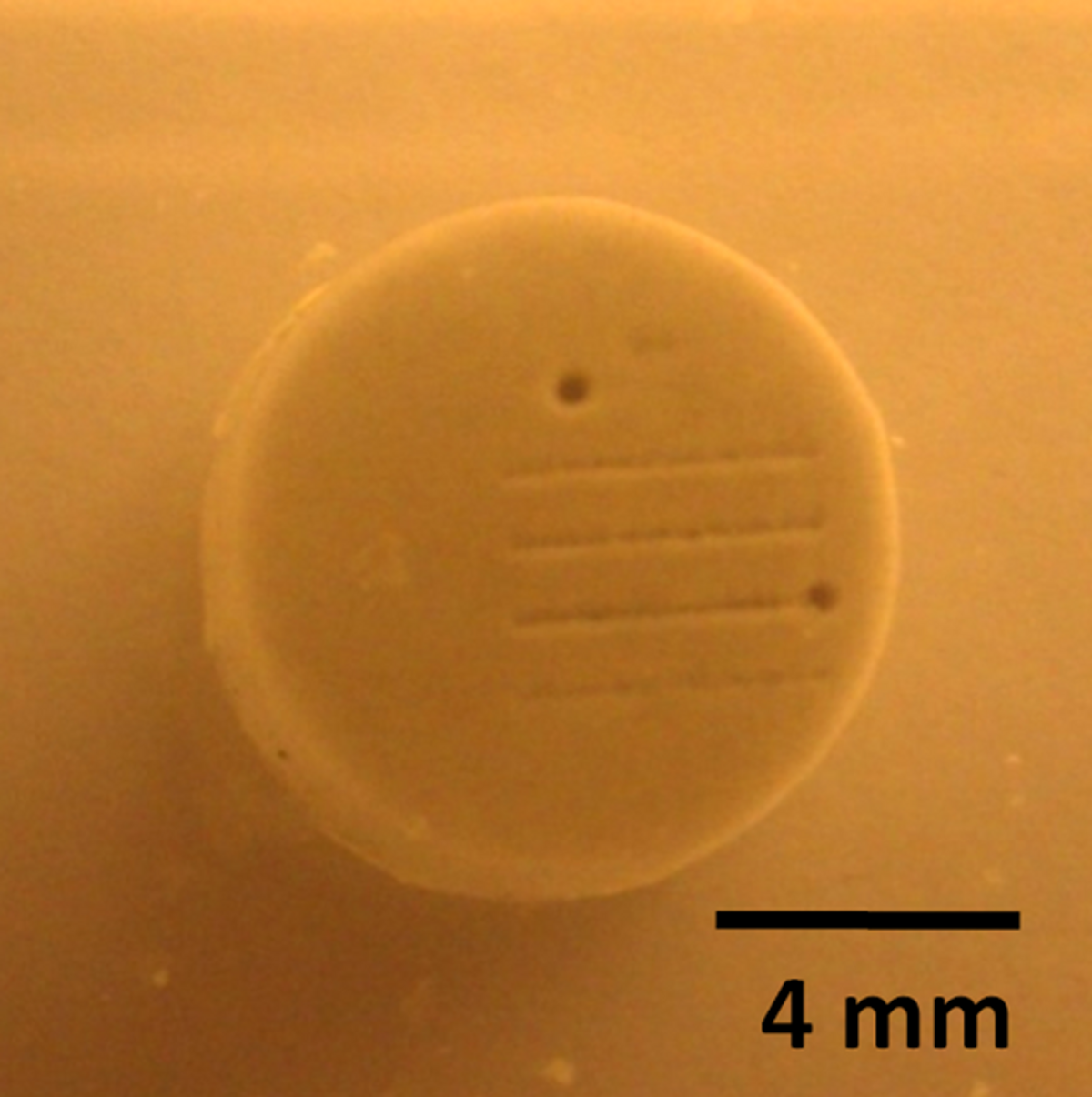

In the image to the right, you can see a150-µm hole that the researchers drilled into a confetti-sized artificial kidney stone.

"A major drawback of current strongly focused ultrasound technology is a bulky focal spot, which is on the order of several millimeters," says Hyoung Won Baac, who worked on the project as a doctoral student and is now a research fellow at Harvard Medical School, in a press release. "A few centimeters is typical. Therefore, it can be difficult to treat tissue objects in a high-precision manner, for targeting delicate vasculature, thin tissue layer and cellular texture. We can enhance the focal accuracy 100-fold."

The research, which was published in the journal Nature (“Carbon-Nanotube Optoacoustic Lens for Focused Ultrasound Generation and High-Precision Targeted Therapy”), coated a concave lens with a nano-composite film of carbon nanotubes (CNTs) and elastomeric polymer. A pulsed laser source is aimed at the lens. The CNTs absorb the light coming from the laser which generates heat. The polymer expands from the heat being generated by the CNTs. This rapid expansion of the polymer amplifies the signal.

The CNT-coated lens when coupled with a pulsed laser is capable of extreme optoacoustic pressures of >50 megapascals. This unprecedented level of pressure results in both shock effects and cavitation without heat being used on the target.

While recent research in sharpening sound waves—at least for imaging devices—has led to exotic acoustic hyperlenses made from metamaterials, the underlying technique behind this device’s conversion of light to sound goes back to at least Thomas Edison. But to date the sound projected from devices employing these techniques was not strong enough to prove useful in medical applications.

"We believe this could be used as an invisible knife for noninvasive surgery," Guo says in a university press release. "Nothing pokes into your body, just the ultrasound beam. And it is so tightly focused, you can disrupt individual cells."

It may still be a while before your surgeon is able to wave a wand over you and send you back to your hospital room without a scar—the technology hasn't even been tested on animals yet—but we may get there well before the 23rd century.

Photo: Hyoung Won Baac

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.