The long list of attempts to use the sun to split water, and thus isolate hydrogen, has always had one big issue: energy conversion efficiency. Sure, solar-based water-splitting processes don’t yield carbon dioxide byproducts like those based on natural gas. But their conversion efficiencies are so notoriously low that many have never seen a way for them to make economic sense as a replacement for those based on natural gas. While headlines heralded tenfold increases in solar splitting efficiency, the result was only conversion efficiencies of 2.9 percent.

That is, until now. Researchers at Stanford University have made what they believe to be a significant step in realizing the kind of photovoltaic energy conversion efficiencies that will eventually make solar water-splitting economically competitive with natural gas processes. If they can realize their lofty ambitions for the technique, it could lead to the emission-free hydrogen economy that has for so long been promised.

In research described in the journal Science Advances, the Stanford team achieved conversion efficiency of 6.2 percent. Though this is less than half of the record 14 percent conversion efficiency for solar water splitting, the results do promise a potentially higher ceiling than a single-cell photovoltaic.

Previous devices have been essentially single-junction devices, and, based on the well-known Shockley Queisser limit, these devices are limited to a theoretical maximum of 34 percent efficiency. The Stanford researchers’ invention has multiple p–n junctions made of different semiconductor materials. In this case, the combination consists of a photoactive photoelectrochemical cell and a perovskite solar cell. This design has a theoretical maximum efficiency of more than 45 percent.

However, the 6.2 percent energy conversion efficiency the researchers have already achieved is nothing to sneeze at; it matches the theoretical maximum rate for a bismuth vanadate cell. And it is in this achievement in engineering bismuth vanadate that the researchers have made their most significant breakthrough.

Bismuth vanadate has begun to get recognition as a pretty good absorber of sunlight, but its use is limited by poor conductivity. To overcome this drawback, researchers have made extremely thin layers of the material—200 nanometers or less. But while the resulting sheets have much improved conductivity, they’re so thin that light just passes through them.

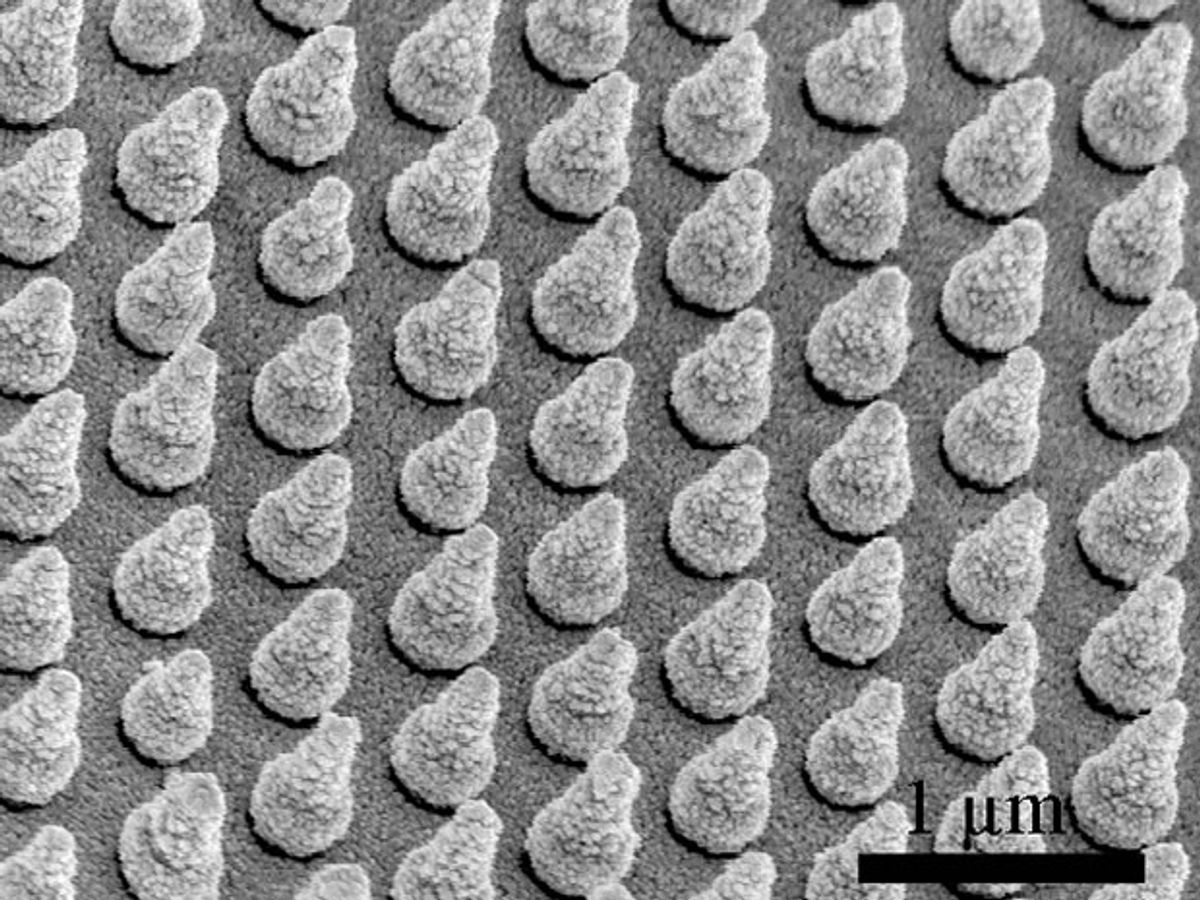

The Stanford researchers, led by Yi Cui, have solved this problem by creating arrays containing thousands of silicon nanocones. The nanocone arrays are deposited on a layer of bismuth vanadate, and these two layers are then placed on a solar cell made of perovskite.

“Nanocone structures have shown a promising light-trapping capability over a broad range of wavelengths,” Cui said in a press release. “Each cone is optimally shaped to capture sunlight that would otherwise pass through the thin solar cell.”

Cui added: “The tandem solar cell continued generating hydrogen for more than 10 hours, an indication of good stability. Although the efficiency we demonstrated was only 6.2 percent, our tandem device has room for significant improvement in the future.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.