Researchers at the U.S. Department of Energy (DOE) Lawrence Berkeley National Laboratory and Argonne National Laboratory (ANL) have developed bimetallic nanocatalysts that are an order of magnitude higher in activity than the 2017 target set for fuel cells by the U.S. Department of Energy (DOE).

This development marks a very long effort by researchers around the world to find some way to apply nanomaterials to fuel cells.

One weak point of fuel cells that nanomaterials could exploit was thought to be the platinum that is used as a catalyst in the system's anode for oxidizing hydrogen and turning it into protons and electrons. Of course, platinum is a precious metal and was seen as a cost point in the fuel cell. However, it’s not been entirely clear that the cost of platinum catalysts has been a major factor in slowing the adoption of fuel cells.

Two main obstacles that are widely acknowledged to be keeping fuel cells from gaining wider adoption—at least in the automotive area—are the costs of isolating hydrogen and building an infrastructure that would deliver that hydrogen to the automobiles. Nanomaterials have gained the most attention for isolating hydrogen in the last few yeas at both the commercial level as well as in research labs.

But the hunt for a nanomaterial to replace platinum as a catalyst inside the fuel cell never went away, bringing us to Berkeley Lab and ANL’s state-of-the-art fuel cell catalyst.

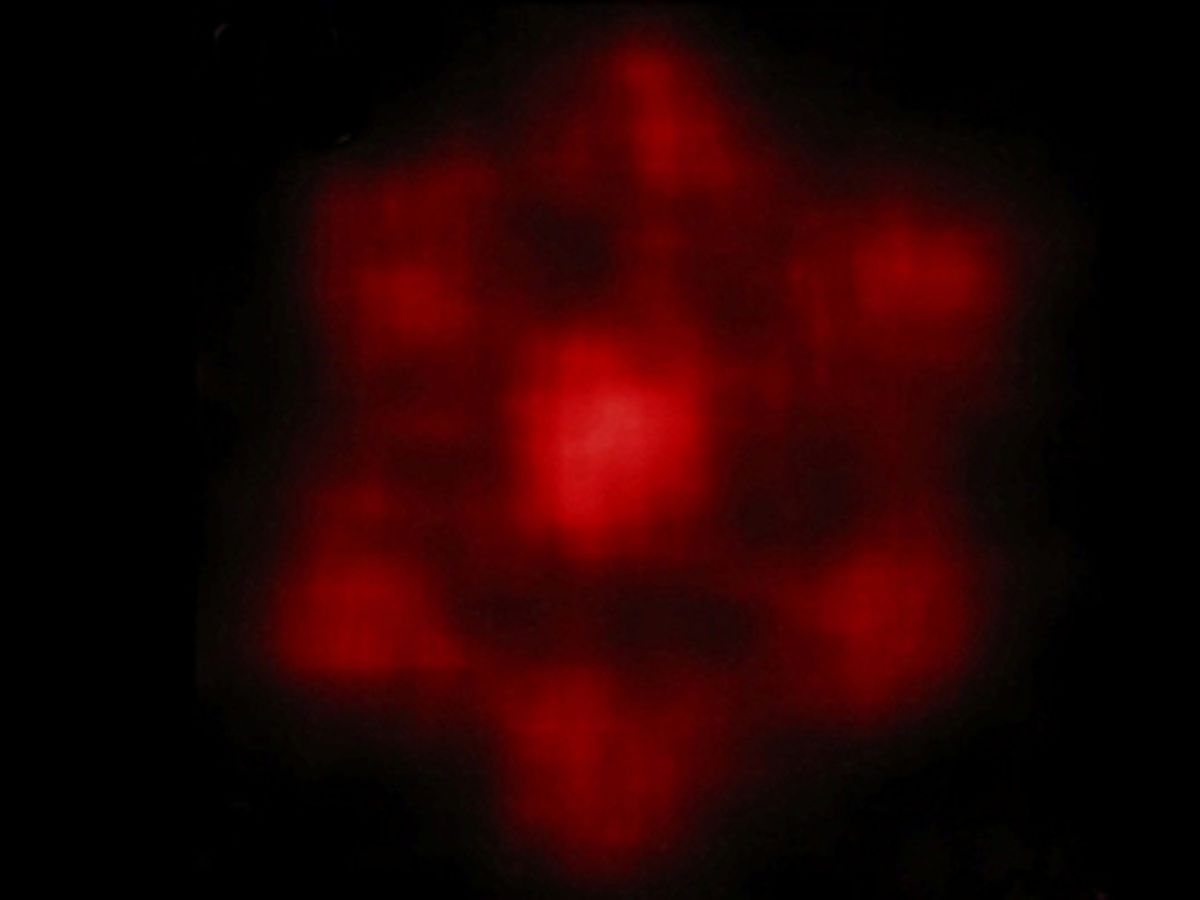

In research, which was published in the journal Science ("Highly Crystalline Multimetallic Nanoframes with Three-Dimensional Electrocatalytic Surfaces"), the team describe a polyhedral-shaped nanoframe consisting of platinum and nickel. Yes, there’s platinum, but a lot less of it than is typically used for fuel cell catalysts. In addition to using less platinum the catalysts are much more reactive, making the fuel cell more efficient.

“We report the synthesis of a highly active and durable class of electrocatalysts by exploiting the structural evolution of platinum/nickel bimetallic nanocrystals,” said Peidong Yang, a chemist with Berkeley Lab’s Materials Sciences Division, in a press release. “Our catalysts feature a unique hollow nanoframe structure with three-dimensional platinum-rich surfaces accessible for catalytic reactions. By greatly reducing the amount of platinum needed for oxygen reduction and hydrogen evolution reactions, our new class of nanocatalysts should lead to the design of next-generation catalysts with greatly reduced cost but significantly enhanced activities.”

The trick to the research was turning platinum and nickel solid polyhedral nanoparticles into the hollow frame structures. This was accomplished by soaking the a bimetallic nanoparticle in solution for either two weeks at room temperature, or for 12 hours at 120 degrees Celsius. The solution acts as a solvent that eats way the solid structure of the polyhedral nanoparticle, leaving behind just hollow frame.

The same technique can be applied to other multimetallic catalysts, according to Yang, making him quite optimistic about its commercial viability as a process. Whether it will prove to be a factor in promoting the adoption of fuel cells, remains to be seen.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.