The use of semiconductors in optoelectronic applications has had a bit of thickness problem. For photovoltaics, the need for relatively thick semiconductor thin films has added some significant cost to their manufacture. In other optoelectronic applications, the thick semiconductor materials are getting quite bulky even as the devices they are used in continue to shrink in size.

In two separate research projects, both these issues have been tackled. In one, researchers from North Carolina State University (NCSU) have developed a computer model that indicates that a new design will improve the light absorbing efficiency of semiconductors in thin film solar cells. In the other, a team at the University of Buffalo has developed a strategy that should enhance the light absorbing quality of semiconductors used for nanocavities, which have applications in camera sensors as well as photovoltaics.

The NCSU research, published in the journal Scientific Reports (“Semiconductor Solar Superabsorbers”), used light trapping techniques to determine the intrinsic absorption efficiency for any given semiconductor material. They discovered that in order to maximize the light-absorption efficiency for the material, the light-trapping efficiency had to be equal to the intrinsic absorption of the semiconductor materials.

“We first theoretically predicted the maximum solar light absorption efficiency in given semiconductor materials, and then proposed a design that could be readily fabricated to achieve the predicted maximum,” said Dr. Linyou Cao, an assistant professor at NCSU, in a press release. “We developed a new model to do this work, because we felt that existing models were not able to find the upper limit for the solar absorption of real semiconductor materials. And if this works the way we think it will, it would fundamentally solve light-absorption efficiency problems for thin film solar cells.”

When the new design was used in their models, the NCSU researchers report being able to reduce the thickness of the amorphous silicon from 100nm, which is the current state-of-the-art, down to 10nm.

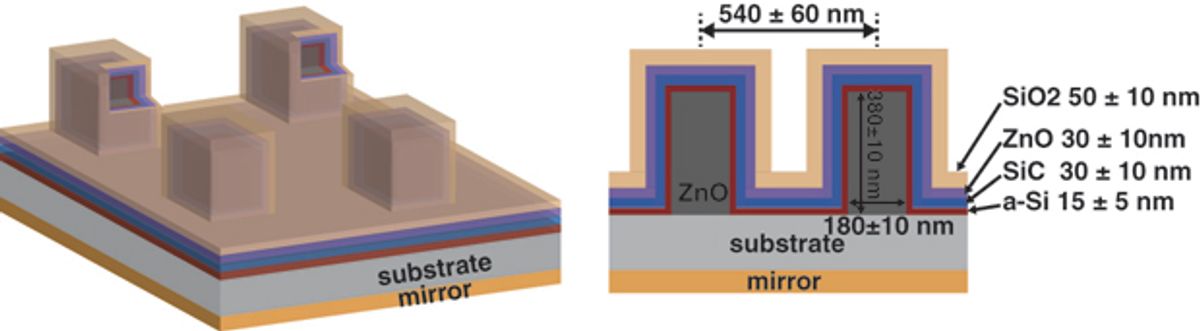

In collaborative research between the University of Buffalo and two Chinese universities, the researchers were also able to put thin film semiconductors on a diet by employing an interference effect in the nanocavities that overcomes the limitation between the light absorption and the film’s thickness. Two years ago, researchers at Harvard University were successful at combining thin films of a semiconductor with a gold surface to achieve the effects that the Buffalo researchers now report. However, the drawback in that work was that it needed to use gold, which is fairly expensive.

The Buffalo team's work, which was published in the journal Advanced Materials (“Nanocavity enhancement for ultra-thin film optical absorber”), demonstrated that inexpensive metals like aluminum could be used in nanocavities and still achieve this effect.

“We illustrated a nanocavity, made with aluminum or other whitish metals and alloys that are far less expensive, can be used to increase the amount of light that semiconducting materials absorb,” said Suhua Jiang, associate professor of materials science at Fudan University in China, in a press release.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.