An international team of researchers has combined ink-jet printing and self-assembling block copolymers to create a hybrid between top-down and bottom-up manufacturing. This new hybrid approach to building nanostructures promises to overcome the obstacles of fabricating nanostructures out of polymers and other soft materials.

The research, which was published in the journal Nature Nanotechnology ("Hierarchical patterns of three-dimensional block-copolymer films formed by electrohydrodynamic jet printing and self-assembly"), found that by using self-assembling block copolymers in combination with ink-jet printing that the resolution for even the best ink jet printers could be improved from approximately 200 nanometers down to about 15 nm.

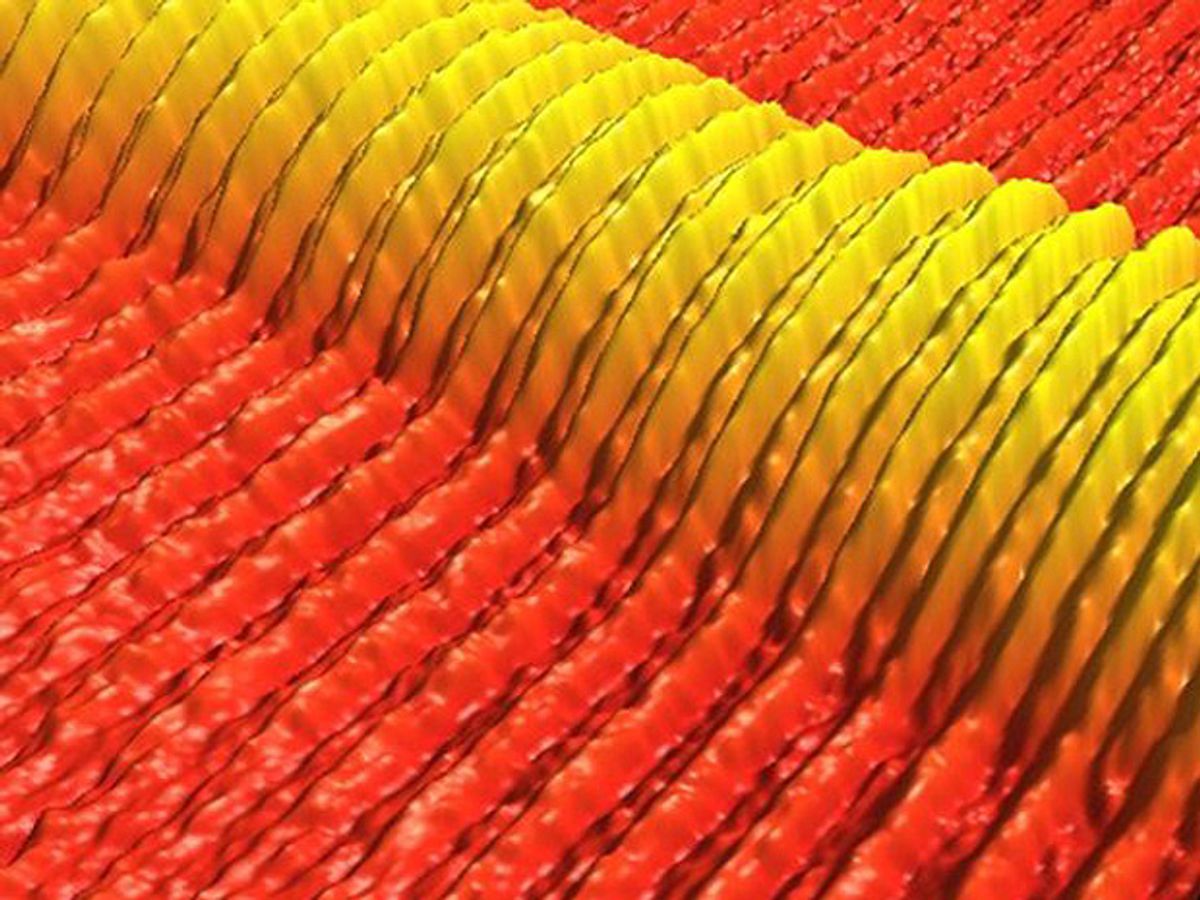

Block copolymers are chain like molecules made up of blocks of two types of chemicals. (Imagine a string of Christmas lights having a repeating pattern of 5 green lights and 5 red lights.) Under the right circumstances, such copolymers can fold up to form patterns such as a repeating array of holes.

The ITRS roadmap has long identified block copolymers for use in reducing chip feature sizes. For years block copolymers have demonstrated their usefulness in creating self-assembled photoresists for chip manufacturing.

While the potential for self-assembling block copolymers have long been understood, this work—which is a cooperative effort of researchers from University of Illinois at Urbana-Champaign, the University of Chicago, and Hanyang University in Korea—adds an important twist.

“The most interesting aspect of this work is the ability to combine ‘top-down’ techniques of jet printing with ‘bottom-up’ processes of self-assembly, in a way that opens up new capabilities in lithography—applicable to soft and hard materials alike,” said John Rogers, a materials science professor at Illinois and one of the authors of the paper, in a press release.

In the work described, the international team turned to the Belgium-based nanoelectronics powerhouse Imec to create chemical patterns over large areas of a substrate with high precision. The research team in Illinois then used ink jet printing to deposit block copolymers on top of these patterns. The block copolymers would self-organize following the patterns laid on the underlying template. The result was that it created patterns that had a greater resolution than the template itself.

While previous work had managed to deposit films on these templates, the result was that the patterns only possessed one characteristic feature size and spacing. With the ultra-precise ink-jet printing tool, it became possible to create multiple dimensions in one layer.

“This invention, to use inkjet printing to deposit different block copolymer films with high spatial resolution over the substrate, is highly enabling in terms of device design and manufacturing in that you can realize different dimension structures all in one layer,” said Paul Nealey, a professor at the University of Chicago and co-author of the paper, in the press release. “Moreover, the different dimension patterns may actually be directed to assemble with either the same or different templates in different regions.”

Image: Serdar Onses/University of Illinois-Urbana

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.