Initial hopes were that graphene and its cousin the carbon nanotube could serve as a replacements to activated carbon to push supercapacitors to the equivalent storage capacity of batteries. That hope soon waned when it became apparent that these carbon nanomaterials don’t even have the theoretical surface area—one of the key features for higher storage capacity in supercapacitors—of activated carbon.

As far back as four years ago, research started to move away from just trying to beat the energy density (the amount of energy stored per unit mass) of supercapacitors using activated carbon, but instead started looking at the interesting structures that could be built using graphene and carbon nanotubes as the electrode material for supercapacitors. This meant that new, smaller supercapacitors could be used to power microelectronic devices with unusual geometries.

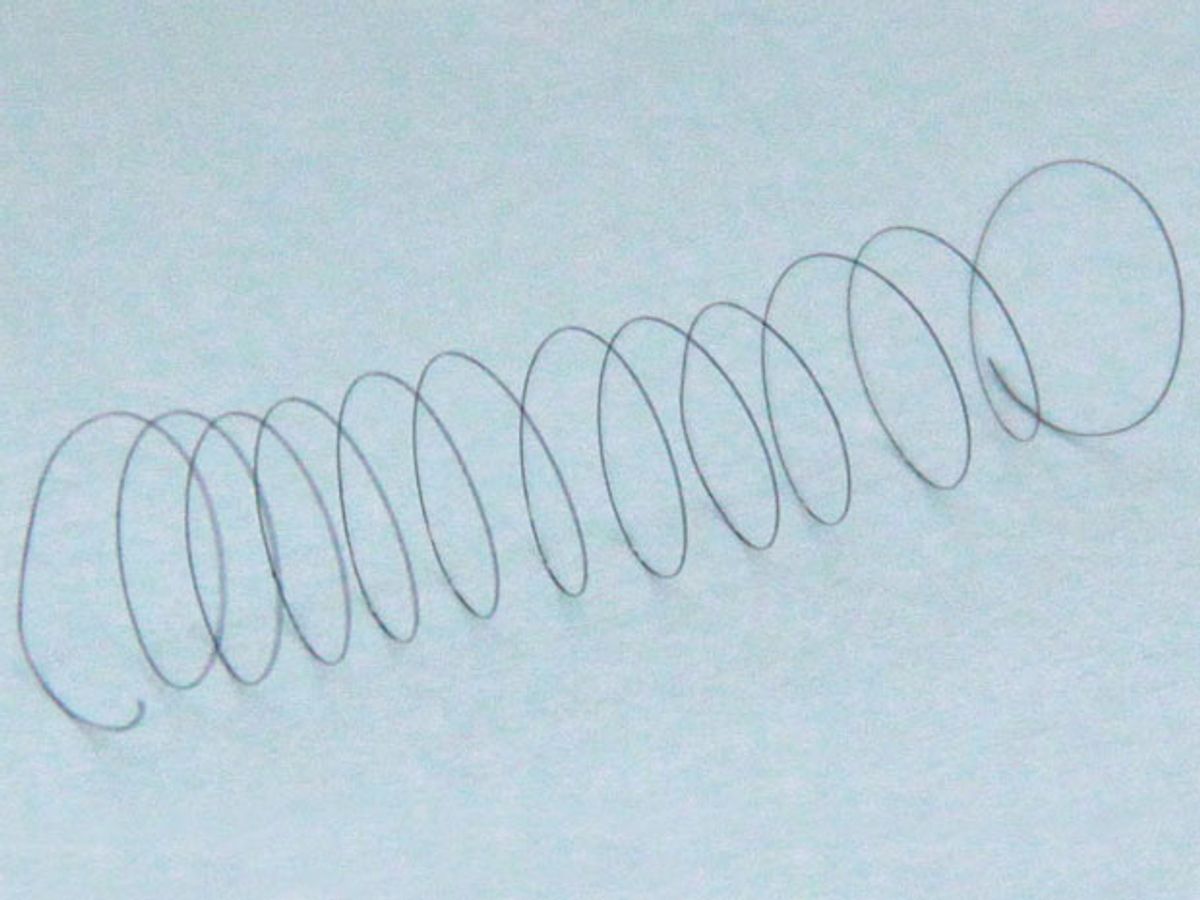

Now an international team of researchers from Nanyang Technological University (NTU) in Singapore, Tsinghua University in China, and Case Western Reserve University in the United States has realized one of these potential new applications by developing a fiber-like supercapacitor made from both graphene and carbon nanotubes that could be woven right into clothing.

In keeping with the new fiber-like geometry of the supercapacitors, the researchers have released figures on the energy density of the novel supercapacitors by volume rather than by mass. They claim that the volumetric energy density is the highest yet reported for carbon-based microscale supercapacitors: 6.3 microwatt-hours per cubic millimeter, which is comparable to a 4-volt-500-microampere-hour thin-film lithium ion battery that can be used to power smart cards and RFID tags.

This record-breaking figure for volumetric energy density addresses one of the weaknesses of typical, activated carbon-based supercapacitors. Using activated carbon on the electrodes of supercapacitors could approximate the energy density of batteries by mass, but when it came to volume they were woefully deficient because they require large amounts of accessible surface area to store energy.

In research reported in journal Nature Nanotechnology, the team demonstrated that their hybrid fiber could store energy along its entire length, providing huge amounts of accessible surface area—396 square meters per gram of hybrid fiber.

The researchers produced the fiber-like supercapacitor by heating a solution of graphene and carbon nanotubes. The graphene and carbon nanotubes self assemble into an interconnected, porous network that runs the entire length of the fiber. The researchers have made flexible fibers as long as 50 meters and having a charge capacity of 300 Farad per cubic centimeter.

"We have tested the fiber device for 10 000 charge/discharge cycles, and the device retains about 93 percent of its original performance, while conventional rechargeable batteries have a lifetime of less than 1000 cycles," said Yuan Chen, a professor of chemical engineering at NTU, in a press release. "The fiber supercapacitor continues to work without performance loss, even after bending hundreds of times.”

The researchers envision the supercapcitor fibers being woven into clothing that could power biomedical monitoring devices a patient wears at home.

The next steps for the researchers will be to scale up the production method to bring down its costs to make it more attractive for commercialization. Meanwhile they will also be looking into applying the supercapacitor fibers solar cells, biofuel production, wearable optoelectronics, and other systems.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.