Two of the main showstoppers to carbon nanotubes (CNTs) making a major impact in electronics have been putting them where you want them to go and separating the semiconducting variety from the metallic ones.

It’s not clear that the solutions to these issues have opened the door to CNTs being the go-to solution in a postsilicon electronics world. But at least there are some solutions being proposed, if not developed. That has not been the case for another problem with carbon nanotubes: the difficulty in getting uniform electrical-resistance measurements.

Now research teams at Rice University and Swansea University in the United Kingdom, both under the supervision of Andrew Barron (who teaches at both universities), have shown that cleanliness is the key to getting more accurate resistance measurements for CNTs. In the process, the researchers may have discovered just how far future electronics can go into the nanoscale when using carbon nanotubes.

In research described in the journal Nano Letters, Barron and his team performed painstaking resistance measurements on both multiwalled CNTs as well as single-walled CNTs, after trying various methods for cleaning the CNTs of any contaminants. The upshot was that the more impurities they could remove, the more accurate and consistent were the resistance measurements.

Semiconducting CNTs should follow the same resistance principles as any other wire, becoming progressively more resistant to current along their length. However, that has rarely been the case.

Part of the issue is that carbon nanotubes contain many impurities, according to Barron, and there are an equally large number of ways that people have cleaned them.

To bring some method to all of this, Barron and the teams at Swansea and Rice looked at individual carbon nanotubes. “Typically, resistance is measured not on individual CNTs but in bundles or wires,” says Barron. “Getting a consistent result on single CNTs means we can understand how much of an issue cleaning is.”

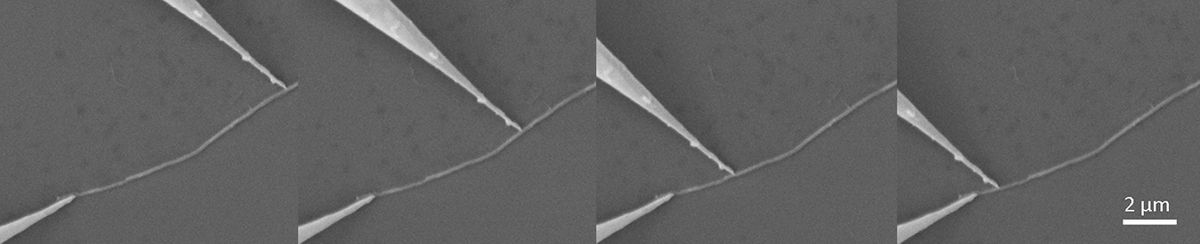

The cleaning started with either heating the CNTs in a vacuum or bombarding them with argon ions to clean their surfaces. At this point, they could attach their probes to either end of the CNTs to test their resistance, just as you would do with a wire. The difference, of course, is a nanotube is so small that the tungsten probes had to be attached with the aid of a scanning tunneling microscope (STM).

When the CNTs were clear of contaminants, resistance increased the further you traveled along the wire, as it should. However, the slightest contaminant would throw a wrench into the whole measurement, and indicated why it has proven so difficult to get consistent and reliable measurements of resistance in CNTs.

After trying a variety of temperatures for heating the CNTs (specifically termed annealing), the researches settled upon annealing CNTs at 500 degrees Celsius (932 degrees Fahrenheit) to ensure enough contamination had been removed from them to measure resistance accurately.

By reaching this level of decontamination, it should become possible to achieve the conductivity desired in CNTs without doping or other tricks. According to Barron, if the CNTs are sufficiently decontaminated, you can tailor their conductivity by placing the contacts in the right spot. This leads to the idea that there may be a limit on the size of nanotube-based electronic devices.

The limit appears to be based on the generation of depletion zones around the contacts, according to Barron. Depletion zones occur in the conducting region of a material when all the charge carriers have been removed. In this case, if the contacts are less than one micron apart, then the depletion zones begin to overlap, changing the electronic properties of the material from a conductor to a semiconductor.

“We are now looking at a range of contacts to determine if this region can be decreased in size,” added Barron.

Barron sees this work as having encouraged a more basic understanding of the electronic properties of CNT through experimental work, as opposed to theoretical work.

To further this experimental research, Barron is looking to collaborate with other researchers and industry to make accurate measurements on individual CNTs and CNT devices in order to better understand the limitations and potential for CNTs in electronic applications.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.