While the long road to commercial success for quantum dots seemed to reach its end when Samsung’s first quantum dot televisions shipped this spring, the material still is relatively expensive to make, limiting its commercial impact.

Now researchers at the University of Illinois Urbana Champaign (UIUC) have attempted to address the expensive production costs of quantum dots, and at the same time, improve their performance and efficiency.

In research published in the journal Applied Physics Letters, the UIUC team developed a method to pull out more efficient and polarized light from quantum dots over a large-scale area. The technique involves combining quantum dots with photonic crystal technology.

The researchers started by embedding quantum dots into novel polymer materials that, the researchers explain, maintain a high quantum efficiency, which is a measurement of a device's electrical sensitivity to light.

Once the quantum dots were embedded into the polymer, the researchers used a printing technology known as electrohydrodynamic jet (e-jet) to print the material as photonic crystal structures. The level of precision afforded by this method reduces the number of quantum dots that are typically wasted in the process.

Quantum dots are nanoscale semiconductor crystals that, when they absorb the right amount of energy, give off energy as colored light. The process developed by the UIUC researchers enables the photonic crystals to control the direction of the light that the quantum dots emit. This control essentially results in polarized light, which is more intense than that produced by an unmodified quantum dot.

So, the process ticks a few boxes. It presumably could lower the production costs of quantum dot-enabled devices by requiring fewer of the crystals to fabricate a device. It also yields a device that is able to produce more intense light with less energy.

“Since screens consume large amounts of energy in devices like laptops, phones, and tablets, our approach could have a huge impact on energy consumption and battery life,” said Gloria See, the lead author of the paper, in a press release. She added:

If you start with polarized light, then you double your optical efficiency. If you put the photonic-crystal-enhanced quantum dot into a device like a phone or computer, then the battery will last much longer because the display would only draw half as much power as conventional displays.

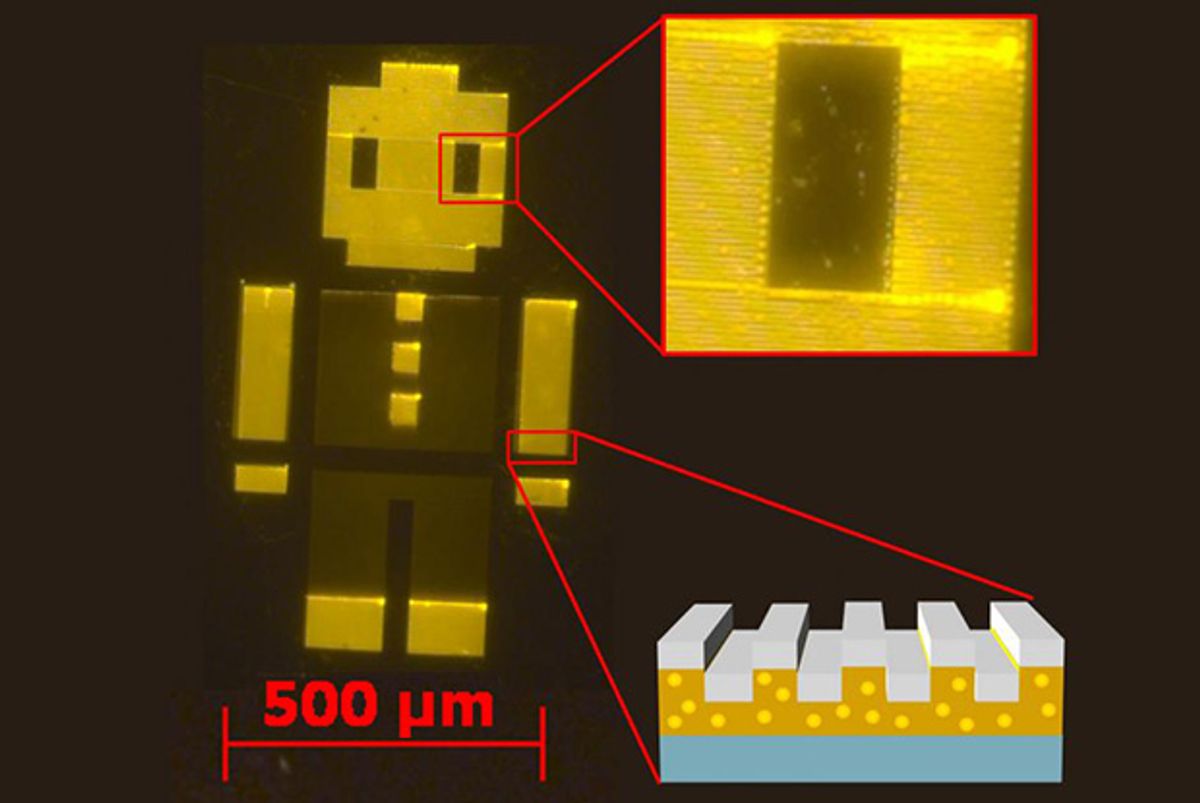

To demonstrate their process, the researchers produced a miniature device, dubbed “robot man,” that’s roughly 1 millimeter tall. In the image of the robot man, it is possible to see the yellow material, which is made up of the photonic crystal material studded with thousands of quantum dots.

“We made a tiny device, but the process can easily be scaled up to large flexible plastic sheets,” See said in the release. “We make one expensive ‘master’ molding template that must be designed very precisely, but we can use the template to produce thousands of replicas very quickly and cheaply.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.