Last August, we reported on work out of the U.S. Department of Energy’s SLAC National Accelerator Laboratory and Stanford University in which the nanomaterial molybdenum disulfide was used to kill 99.999 percent of bacteria in water within just 20 minutes—a process that would otherwise take up to two days if only the ultraviolet (UV) light from the sun were used as a disinfectant.

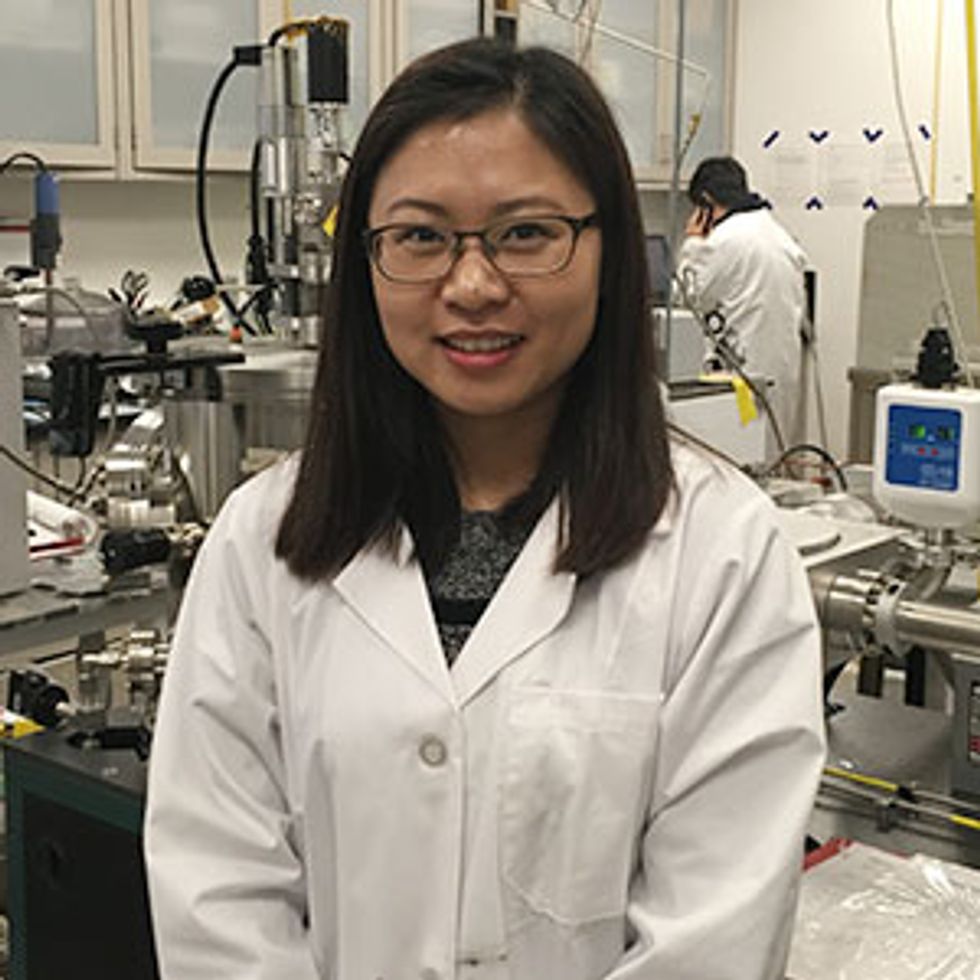

In a meeting last week with Chong Liu, the post-doc in Yi Cui’s lab at Stanford who was the lead author of that research, it appears water purification is just the start for the capabilities of this line of research that has had a number of incarnations.

“We have several water-related products,” said Liu in a meeting at the lab. “At the beginning, we had water disinfection, which is to use an electrical field to kill the bacteria. The electrical field can punch holes in the bacteria membrane causing them to die because the inner membrane composition is exposed to the environment.”

The problem with using an electrical field to kill bacteria, according to Liu, is that it’s necessary to have a very high electrical field on the order of 10 to 6 volts per meter. “As a result, you have to use nanomaterials. In this case, we used nanowires to enhance the electrical field locally, then you can use less energy. Otherwise, you have to use kilovolts, which is not safe to treat water. But after using nanomaterials you can get below 10 volts.”

The practice of introducing an electrical current into the water and enhancing the electrical field locally through the use of nanowires was soon developed into a new phase of the research involving the use of solar light to catalyze water disinfection. This direction led to the research we reported on last summer in which the molybdenum disulfide films are aligned vertically on the surface of glass so that a pane of the material was able to make use of the full visible solar spectrum.

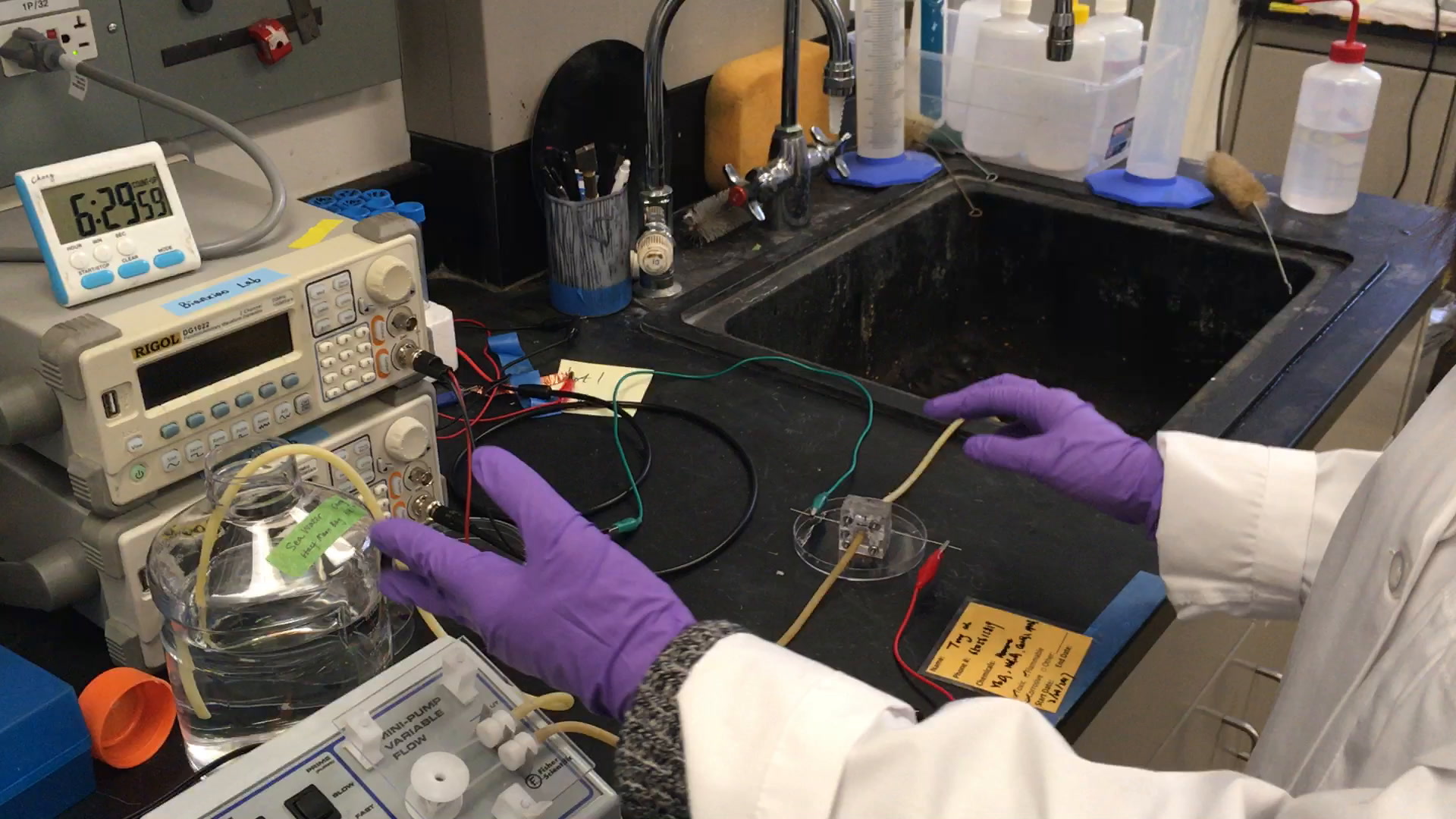

But in Liu’s latest piece of research, published in the 17 February edition of Nature Energy, she has found a way to exploit a nanostructured carbon felt material that has been functionalized with the polymer amidoxime to extract trace amounts of uranium from seawater.

The seawater is pumped through a filter electrode made from carbon felt and coated with amidoxime. The filter electrode is much larger than a membrane material, offering less resistance for the water to pass through and thereby reducing energy costs. You can see a demonstration of the process in the video below.

Amidoxime has long been used for uranium extraction. It can recognize uranium and absorb it. But previously the amidoxime was simply placed into the seawater to just soak, relying on absorption to extract the uranium.

“What we developed here is to use a electrochemical process,” said Liu. “But it’s an alternative method of electrochemical processes for extracting uranium because if you're thinking of putting electricity into water, then you are splitting water to generate hydrogen and oxygen, which is the byproduct you don't want. You're wasting energy to do that and all you really want to do is extract uranium. So to avoid the water splitting, we using an alternating current that will limit the transport of electrons that generate hydrogen.”

While Liu concedes that extracting uranium from the land is currently cheaper than getting it out of seawater, the problem of environmental impact always exists with mining. Also, many countries that might want to use uranium for nuclear power don’t have uranium mines.

“We are trying to lower the costs of our seawater extraction process as well,” said Liu. “This is the future of how we will extract uranium.”

While this may be the future of uranium extraction for the time being this research remains a bench top experiment.

“So far we’ve just developed the method; we think there’s a lot of room to improve,” she said. “One direction is to develop better materials for extracting uranium. Also, the electrochemical method part you need to optimize the system to use less energy, and after that maybe there’s a need for a larger scale experiment.”

With the challenges still ahead, Liu explained that perhaps the biggest challenge she initially faced in developing this technology was analyzing the market to see where there were significant unmet needs.

“You need to analyze what is currently being used in the field,” she said. “You see if there are limitations. For instance, if you wanted to develop a safe way to provide water to developing countries, you know you will be dealing with large volumes of water, so you need to do it very fast. You want a high-speed, high-efficiency device. So if we target the high speed, high efficiency, you look at what’s the current methods to kill bacteria, like chlorine-based. They rely on chemicals and UV light which is very good because it’s free and there’s plenty of it, but it’s slow and weather dependent.”

This is why the first nanowire research was done that generated a localized electrical field because it was a physical method—punching holes in the bacteria—that is very fast. This is the same phenomenon that is used to deliver genes or DNA into cells. But instead of delivering genetic material, you are looking to kill bacteria.

This is Liu’s and her colleagues’s approach to research: Look for a problem and develop ideas to solve the problem and then think of how to realize it in a device.

“It’s a different style,” she said. “I think Yi Cui likes this kind of style very much because he thinks that since we are in the engineering school we really should have research that makes an impact in the real world. He wants to see how we can improve the quality of people’s lives. This is why we target problems first.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.