It was recently reported that used cigarette butts provide a material that yields far better energy density (the amount of energy stored per unit mass) than do many nanomaterials proposed for superconductors. So, it appeared that if graphene were really going to be a replacement for activated carbon on the electrodes of supercapacitors, it had better be able to compete on something more than energy density alone.

Now, researchers at MIT have used graphene to make stretchable supercapacitors to power flexible electronics.

While graphene has not been able to beat activated carbon in terms of surface area for electrodes of supercapacitors, it offers two other key features that activated carbon electrodes lack: because of its superior conductivity, it can operate at higher frequencies, making it useful for filtering circuits in AC rectifiers; and it can be made into engineered structures that enable use in applications that require thinner or just smaller dimensions.

The MIT researchers, whose work was published in the journal Scientific Reports, addressed another shortcoming typical of supercapacitors: the fact that they are very rigid. Making them flexible required a complicated and expensive process.

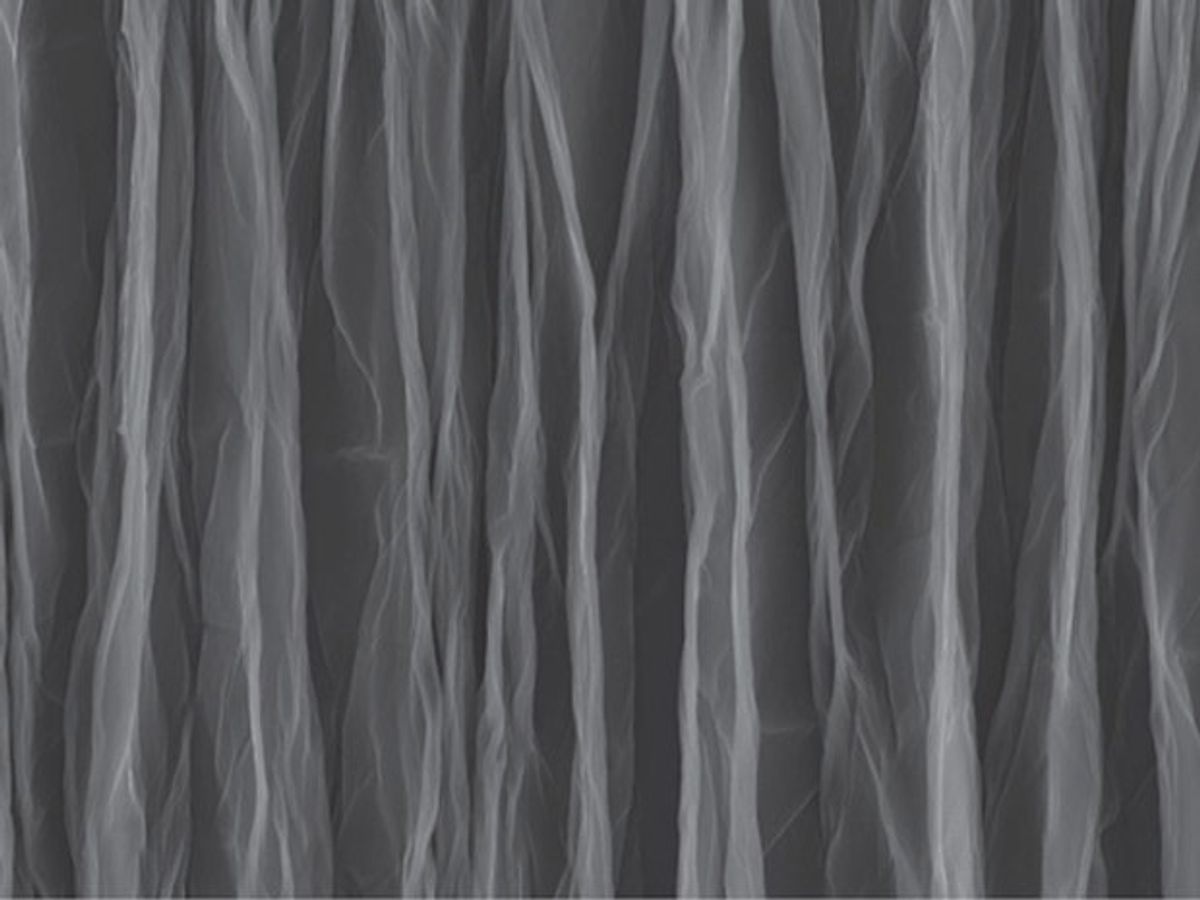

The trick to achieving supercapacitor flexibility was crumpling up the graphene so that when the supercapacitor is stretched the ridges in the material unfold. When completely flattened out, the supercapacitor’s dimensions can expand by up to eight times its size in its crumpled state.

This crumpling up and flattening can be repeated 1000 times without any loss of performance, according to the researchers. “The graphene paper is pretty robust,” said Xuanhe Zhao, an assistant professor at MIT, in a press release. “And we can achieve very large deformations over multiple cycles.”

The process for producing the graphene paper is relatively simple and low-cost compared to the flexible supercapacitors that are produced today. It requires taking a sheet of the material and placing it in a mechanical device that can compress it one direction, creating parallel folds or pleats. Then this folding is repeated so as to give the material its chaotic, rumpled surface.

An insulating layer, made from a hydrogel that is also highly flexible, is sandwiched between two layers of conductive, crumpled graphene.

Dan Li, a professor at Monash University in Australia who was not involved in this research, commented in the release: “Making supercapacitors stretchable has been a great challenge. This paper provides a very smart way to tackle this challenge, which I believe will bring wearable energy storage devices closer.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.