The incandescent lighbulb may be on its last legs. But it could find itself reincarnated at the microscale.

IEEE Fellow Yue Kuo, a professor at Texas A&M University in College Station, Tex., and his former Ph.D. student Chi-Chou Lin, have been developing a new solid-state device that works on the same basic principle.

Like an incandescent lamp, the device emits light by heating up filaments so much that they glow. In this case, however, the filaments are tiny – just 20 to 150 nanometers in diameter – and the bulbs can be made in a semiconductor fabrication plant.

“In simple words, it is the solid-state version of Edison's incandescent lightbulb,” says Kuo. At the IEEE International Electron Devices Meeting in San Francisco last week, he reported that the devices survive more than 7,000 hours under continuous operation.

Kuo has named this creation a “solid-state incandescent LED”. Here the “D” stands for device, not diode, and the device is actually an MOS capacitor. It’s created by sandwiching a thin layer of amorphous, insulating, dielectric material between a conductor and p-type silicon (silicon with an excess of holes). Light escapes through the conductor at the top of the stack, which is made from a transparent conductive film, such as indium tin oxide.

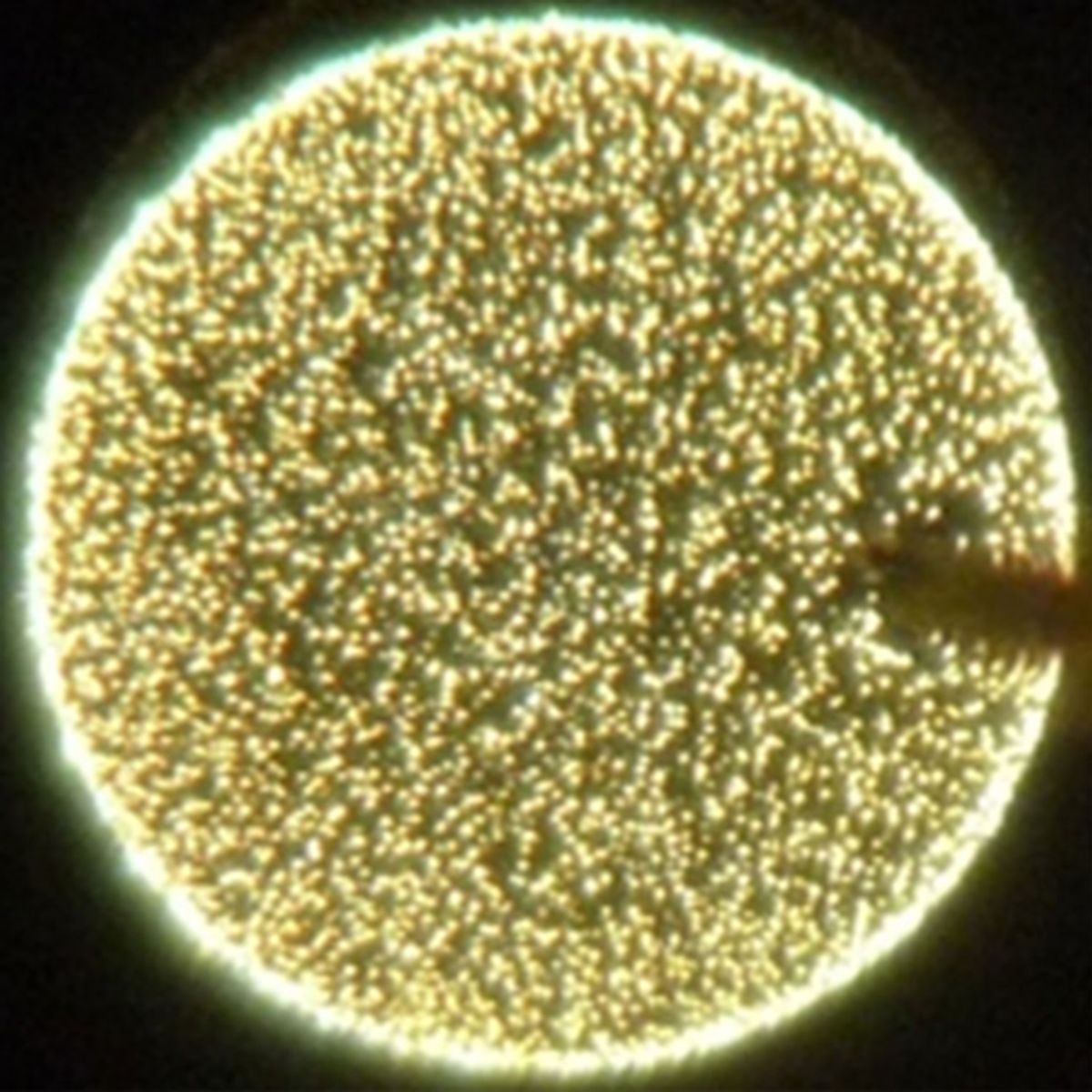

To make the stack emit light, Kuo and Lin apply a voltage high enough to break down the dielectric in the middle of the sandwich. This creates a host of tiny, permanently-conductive filaments. Once the breakdown has occurred, applying a voltage to the device causes current to flow along each filament. Because they have some resistance, they heat up, and emit a pinprick of light through the transparent film. “The light is actually composed of many small dots,” Kuo said.

Like an incandescent bulb, the incandescent device emits white light, over a wide spectral range. This is a pretty big departure from the conventional LED, which emits light of a narrow range of wavelengths. To make white light from such devices, you must pair a blue LED with a phosphor or mix light from red, green, and blue devices.

Kuo and Lin, who have been working on the incandescent device since 2011, have published a few papers now on the device, demonstrating that the mechanism works for several dielectrics, including tungsten oxide and halfnium oxide, which is already used in today’s transistors.

Because these new devices can be made with widely-available materials and basic fabrication techniques, such as sputtering, Kuo says they could be a cheap alternative to conventional LED’s. They might also be used as a light source for on-chip optical communications.

One big catch is efficiency. The team’s preliminary measurements suggest less than 1 percent of the electricity sent in the device is converted to light, although Kuo notes his measurements were taken about 2 millimeters from the device, so light that should have been counted may have been lost.

Kuo expects the device will ultimately produce light more efficiently than a conventional incandescent light bulb, which loses some 90 percent of its energy to heat. That’s because an incandescent bulb’s emission peaks in the infrared, while the incandescent microdevice peaks in the visible part of the spectrum. It’s not clear whether it will ever get close to LED levels.

“Since [the solid-state incandescent LED] is a brand new device, there are many unknowns,” Kuo says. There is still work to be done, he says, to understand the fundamental physics of the device, including the nature of the conductive paths, the potential limits on efficiency, and how the device would ultimately fail.

“I think it’s a very interesting, I would even say, a brilliant idea,” says Michael Shur, an engineering professor at Rensselaer Polytechnic Institute in Troy, N.Y. who has been following Kuo’s work. Shur says the efficiency of the devices has to be improved, but he says he is excited about the practicality of the fabrication method. “Potentially it could be very cheap, it could be very robust, and it could cover a huge area. This is the technology of the future, in my opinion.”

Rachel Courtland, an unabashed astronomy aficionado, is a former senior associate editor at Spectrum. She now works in the editorial department at Nature. At Spectrum, she wrote about a variety of engineering efforts, including the quest for energy-producing fusion at the National Ignition Facility and the hunt for dark matter using an ultraquiet radio receiver. In 2014, she received a Neal Award for her feature on shrinking transistors and how the semiconductor industry talks about the challenge.