Lumotive, a startup in Bellevue, Wash., says it has a compact, long-range lidar sensor that is at least as capable as the best machines from its rivals but smaller, cheaper to make, and more robust.

This announcement, the company’s first, comes after two years of work, seeded by money from Bill Gates and from Intellectual Ventures, a firm founded by Gates’s former science guy, Nathan Myhrvold. Right now Lumotive is showing a benchtop prototype to potential customers; it plans to ship samples toward the end of the third quarter of this year.

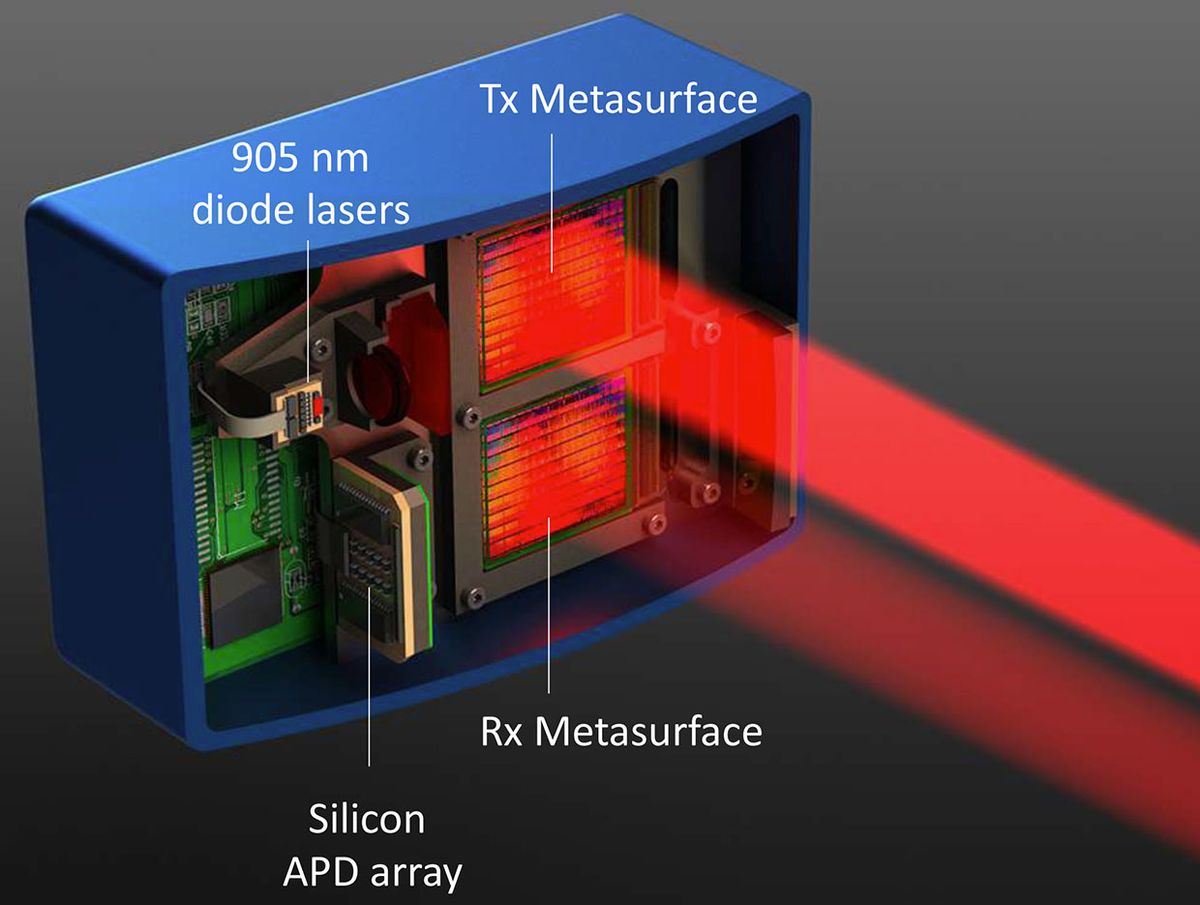

The company steers its beam with what it characterizes as a truly solid-state technology, as compared with the conspicuous moving parts of Velodyne, with its rotating rooftop tower; the large mirror-steered beam of Luminar; and even the tiny MEMS mirrors that control the scanning for Innoviz and other companies.

“MEMS-based systems are still mechanical,” argues Lumotive’s cofounder, Gleb Akselrod, who holds a Ph.D. in optics and photonics from MIT. “One, they’re not robust enough in an automotive setting, and two, the mirrors are so small it’s like looking through a straw. They can’t collect a lot of light, and so they can’t see very far.”

But because Lumotive has a wide aperture—25 by 25 millimeters (1 inch square)—it can transmit and receive the light much more easily, making better use of the collected light. The device can thus see far without having to turn up the brightness. That’s important because the sensor works at 905 nanometers, an eye-sensitive wavelength the company chose because it works with silicon. You need exotic compound semiconductors to make and detect laser light at 1,550 nm, a wavelength that’s easier on the eyes.

Lumotive shines a beam on a liquid-crystal “metamaterial” that has tiny tunable components, each of which can be used to slow down one part of the laser beam with respect to another part. That slowdown shifts the phase, pulling the waves’ peaks and troughs a little back, so when they meet up with their counterparts from the unlagged beam, they interfere. The result is a new beam, pointing in a new direction. You steer the beam by varying the phase shift. Lumotive says it can scan 120 degrees horizontally and 25 degrees vertically.

The method descends from one announced eight years ago by another team funded by Intellectual Ventures, which used metamaterials to steer radio-frequency beams. But the tunable element has to be smaller than the waves they modulate, and light has far smaller wavelengths than radio.

The “secret sauce,” Akselrod says, is in how to tune those liquid crystals. The method involves applying a voltage to each optical element to delay the light and thus shift the phase. “The elements have to be much smaller than the wavelength, so the trick is how to manufacture that in a standard CMOS fabrication system,” he says.

Akselrod says the only true solid-state alternative to his company’s technology is Quanergy’s, which uses phase interference based on a different technology. But that company has not met the expectations it created back in 2016, when it announced it was on the verge of shipping samples.

“They inject a laser beam into a waveguide on a chip, split the beam into other waveguides, pass each part through a phase shifter, then couple the light out of the chip to form the beam,” Akselrod says. “But all of those components have optical absorption, so very little light gets through, and it’s hard to scale and to keep all those waveguides coherent with each other.”

When he compares his device with rival lidars, he says its range (200 meters) and its speed (10 to 20 hertz) are as good as or better than the best sensors out there, including Velodyne’s and Luminar’s. It has 0.1 degree of resolution, and it can detect objects with just 10 percent reflectance—“think a black tire on a road,” says Akselrod. On top of that, he asserts, its compactness (12 by 8 by 6 centimeters) and its solid-state robustness should suit it better to the rugged environment of a road vehicle, even as its silicon-based technology makes it potentially more affordable.

Philip E. Ross is a senior editor at IEEE Spectrum. His interests include transportation, energy storage, AI, and the economic aspects of technology. He has a master's degree in international affairs from Columbia University and another, in journalism, from the University of Michigan.