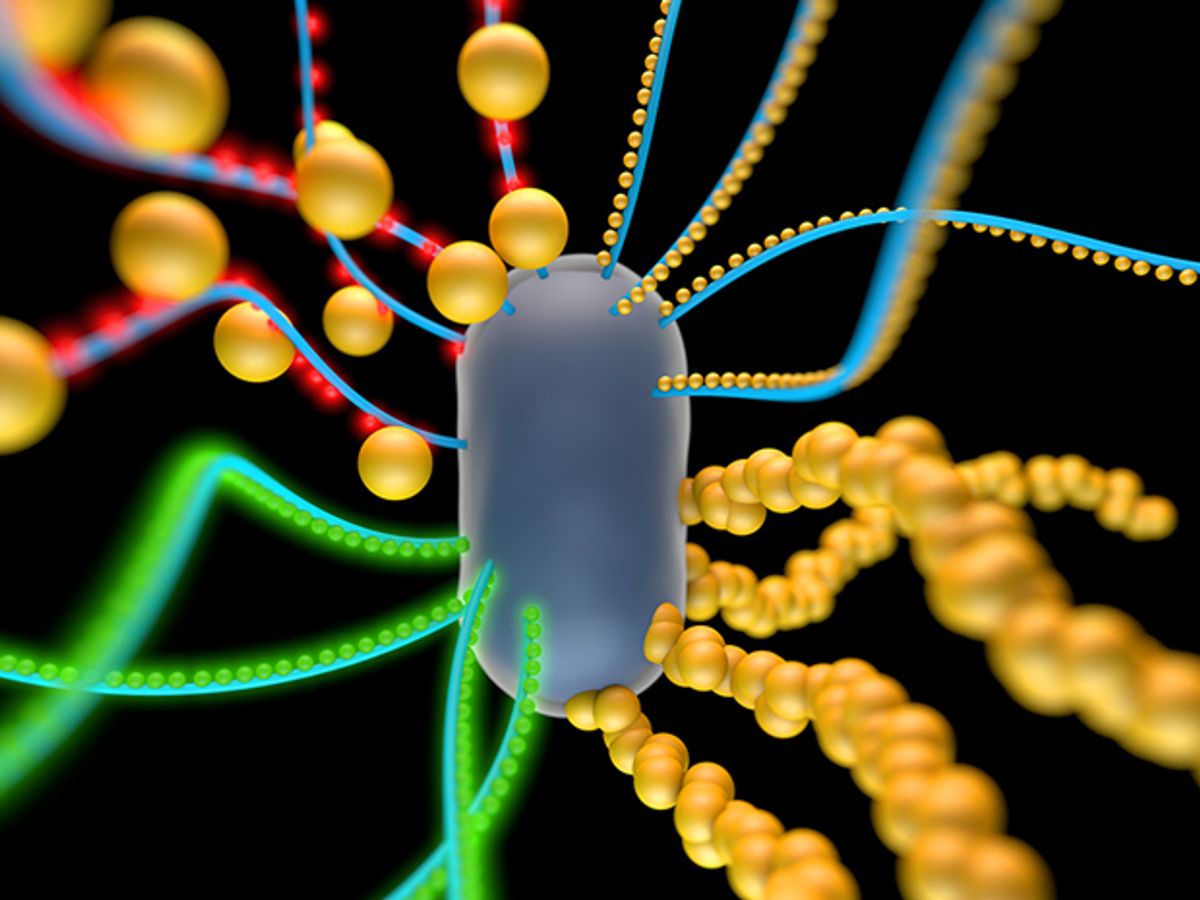

Nearly four decades ago, researchers managed to coax the bacterium Escherichia coli (E. coli) into producing a protein. Now researchers at MIT have devised a way to combine a living E. coli cell with inanimate building blocks, like gold nanoparticles and quantum dots, to create a hybrid “living material.”

The MIT researchers have managed to get the bacterium to produce a biofilm that is able to attach to different nanoparticles, resulting in a hybrid living material that responds to its environment, produces complex biological molecules, and spans multiple length scales. The properties that these living materials take on include the ability to conduct electricity and emit light.

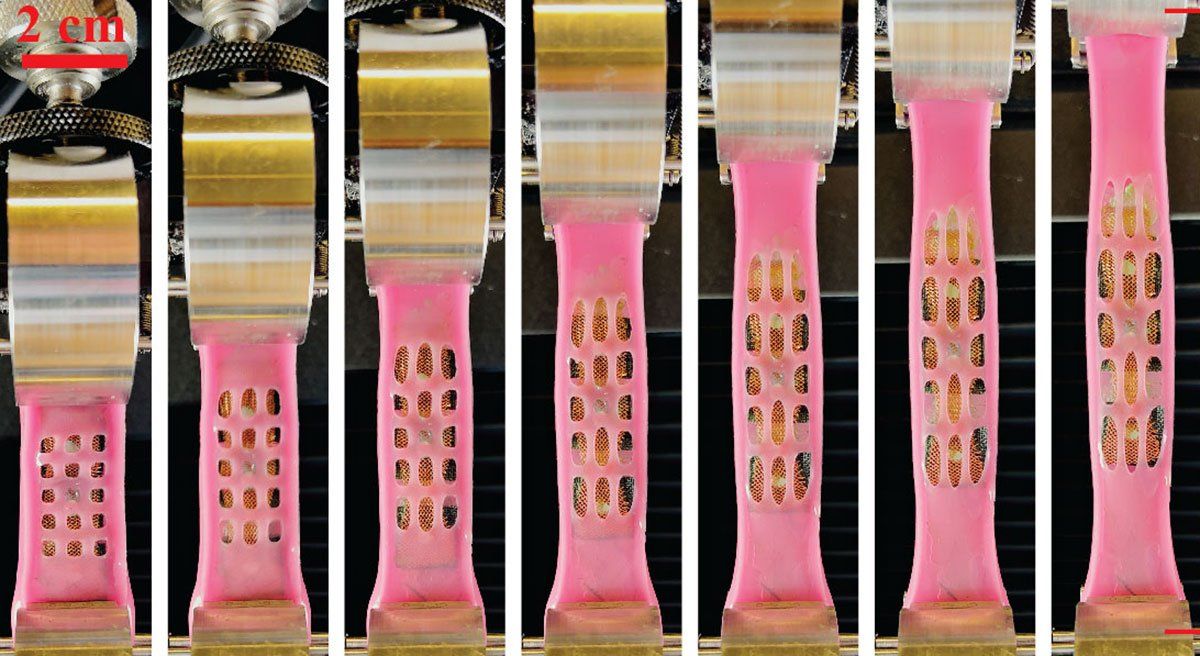

The research, which was published in the journal Nature Materials ("Synthesis and patterning of tunable multiscale materials with engineered cells"), is expected to serve as a demonstration of the new approach's potential to produce larger devices such as solar cells, self-healing materials, or diagnostic sensors.

“Our idea is to put the living and the nonliving worlds together to make hybrid materials that have living cells in them and are functional,” said Timothy Lu, an assistant professor of electrical engineering and biological engineering at MIT, in a press release. “It’s an interesting way of thinking about materials synthesis, which is very different from what people do now, which is usually a top-down approach.”

The researchers chose to use E. coli since it naturally produces a biofilm. This biofilm contains something dubbed “curli fibers,” which are amyloid proteins that help the bacteria attach to surfaces. The researchers modify the repeating protein chain of the curli fibers (called CsgA) by adding protein fragments called peptides. By modifying the curli fibers that attach to different substances, it’s possible to create a range of hybrid materials. They can create gold nanowires that behave like a conducting film or tiny crystals that exhibit quantum mechanical properties.

Perhaps the most significant property of these hybrid materials is that they can communicate with each other. “It’s a really simple system but what happens over time is you get curli that’s increasingly labeled by gold particles. It shows that indeed you can make cells that talk to each other and they can change the composition of the material over time,” Lu said in the release. “Ultimately, we hope to emulate how natural systems, like bone, form. No one tells bone what to do, but it generates a material in response to environmental signals,” said Lu.

Early application ideas for the hybrid materials include batteries and solar cells, but the researchers are also investigating the potential of coating the biofilms with enzymes to catalyze the breakdown of cellulose, which could be useful for converting agricultural waste to biofuel.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.