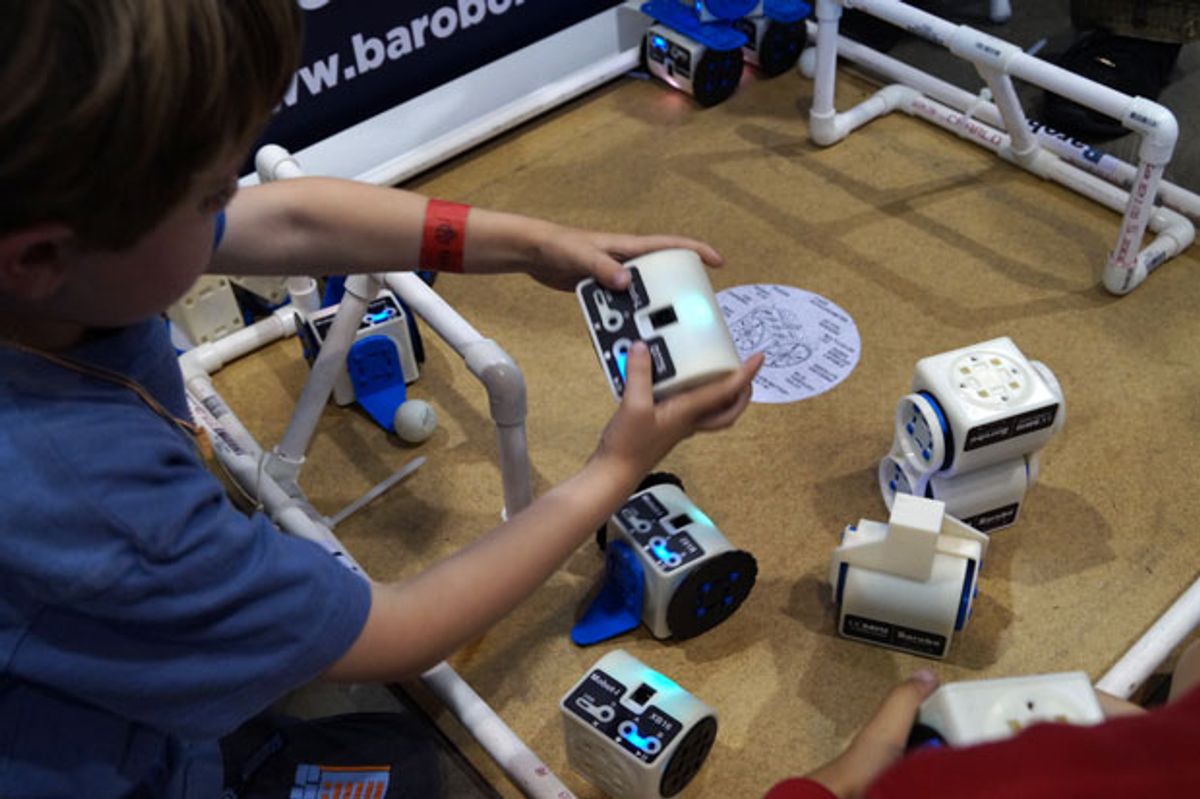

Last month (I don't know how it can possibly be just last month but somehow it is) at Stanford's Robot Block Party, we talked to the guys over at Barobo, who gave us a peek at a modular educational robot system that they were getting ready to Kickstart. The project has now launched, meaning that the time to get a DIY modular robotics kit of your very own is right now.

Barobo's Kickstarter video does an excellent job explaining everything that these modular robots, called Linkbots, are capable of:

We know from experience that robotics comes with a learning curve that would intimidate even Sir Edmund Hillary, so we're always excited to see robots designed to help kids (and those of us who know less than kids) get started in a fun and easy way. It's worth mentioning, though, that there's some serious research behind Linkbot: Graham Ryland, the president of Barobo, worked on iMobot, a modular robotic system that we covered several years ago.

Now, it's true that similar (in size) robotics kits may be a bit less expensive than the $190 per module that a Linkbot will run you (it's discounted for Kickstarter backers), but there are some good reasons for the cost, as the company explains:

"I think the thing that sets Linkbot apart from most robots is our absolute encoding and torque to weight ratio. We want you to do more than just roll, we want you to walk!"

Encoding is the thing that you need to make precise movements with a wheeled robot: it's basically a hardware feature that tells the brain of the robot exactly what the wheels of the robot are doing, and the better your encoders are, the easier time you'll have moving in straight lines and getting from one place to another. Also, if you're using a Linkbot module as something besides a wheel (like an arm), those encoders are what's going to be responsible for precise, repeatable motions.

The advantage of motors with a high torque to weight ratio are pretty straightforward. In the case of most robots, it's not so much about speed that we care about, it's power. Finding motors that can drive a wheeled robot along isn't very difficult (or very expensive), but walking (or grasping) involves moving a lot more mass, since you often end up in situations where most of the weight of the robot is being supported by just one or two motors. For walking to work, you want to have the strongest motor you can in the lightest package possible, which is what Linkbot is trying to do.

If you check out the Kickstarter page, there are still a few Linkbot kits available for $140, which is $50 cheaper than the post-Kickstarter price. Adding modules starts to get expensive rather quickly (two will set you back nearly $400 when you add a Bluetooth-enabled breakout board), which is a bit unfortunate since part of the point of modular robots is to be able to have, you know, modules (plural). But, we're optimistic that multi-Linkbot kits will find their way into schools and other educational settings, while the rest of us will just have to get creative.

[ Kickstarter ] via [ Barobo ]

Thanks Graham!

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.