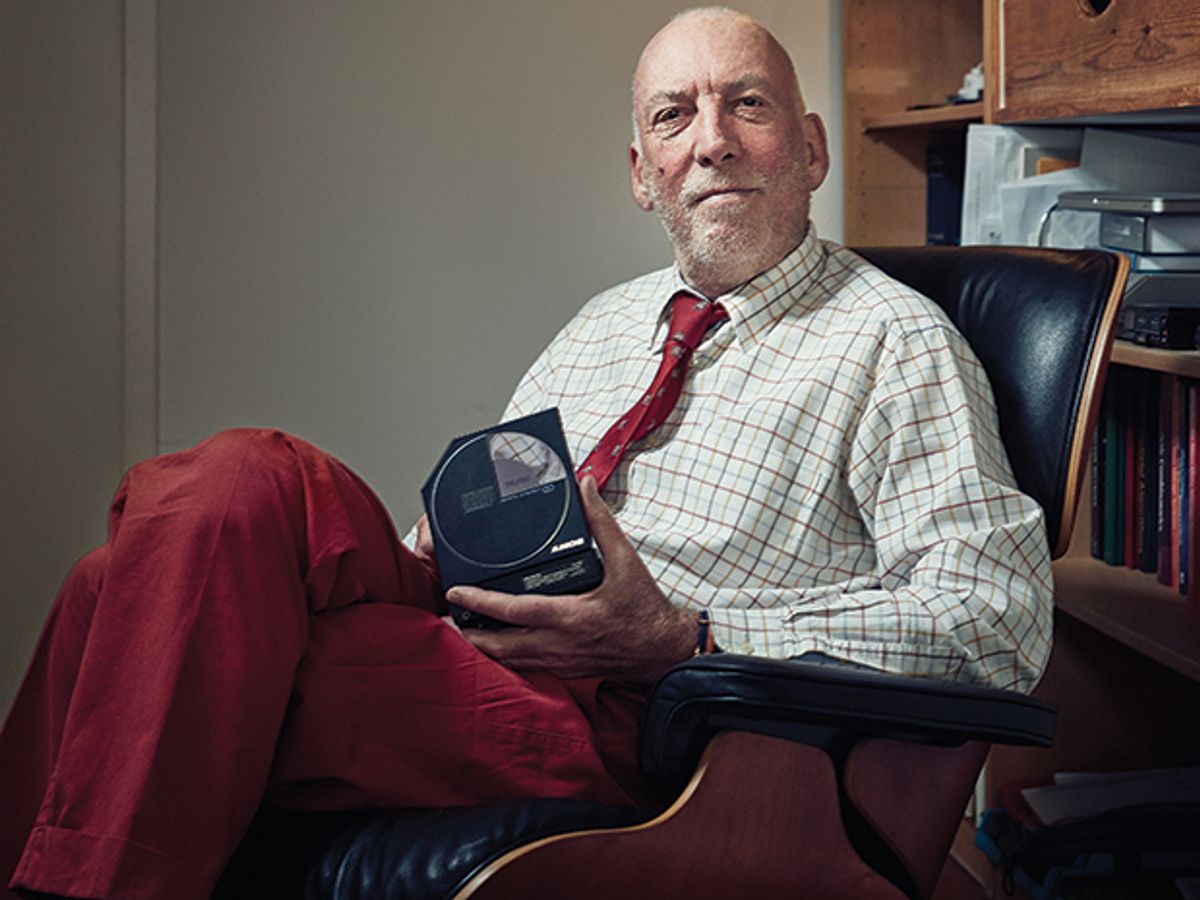

Kees Immink: The Man Who Put Compact Discs on Track

This Dutch researcher created the code that turns bits into pits

Remember vinyl records? More specifically, do you remember the way vinyl records skip when they’re dusty or scratched?

Let me assume you’re old enough to recall that annoyance, or perhaps you’ve experienced that vintage technology more recently. Now think back to when you got your first CD. Small and shiny, packing 74 minutes of music, it seemed magical, even more magical when you noticed that you could treat a disc pretty badly before physical damage affected the way it played.

A lot of different kinds of engineering, of course, went into figuring out how to put music on a CD and play it back so reliably. There’s hardware, including a laser, optics to focus it, and mechanical systems to move the laser and turn the disc. And there’s software—including pulse-code modulation, which turns regular samples of an analog signal into bits, and error-correcting codes, which make sure those bits don’t get corrupted.

And there’s one more piece of the CD puzzle: how to translate the digital bits into physical marks on the disc itself. This piece, known as the channel code, deserves much of the credit for making CDs skip resistant without sacrificing playing time. For this encoding scheme and related optical-recording technology, its creator, Kees Schouhamer Immink, will receive the 2017 IEEE Medal of Honor.

Immink was a young electrical engineer working in the laboratories of Philips, in Eindhoven, Netherlands, when the research effort that was to become compact-disc technology got under way in the mid-1970s. Initially, Immink had nothing to do with the project. Rather, he worked on control theory, assigned to a group of mostly optical engineers developing the analog laser videodisc. Philips introduced the LaserDisc in 1978, and it was a flop. This play-only system couldn’t compete with video cassettes, which could be used to record and had a two-year head start in development. Come 1979, Immink was a research engineer without a project.

Meanwhile, another research group at Philips had developed a prototype of a laser-based digital audio disc system, while Sony engineers had demonstrated a similar technology. The two systems differed enough in the details to render them completely incompatible. But instead of racing separately to market and triggering a format war, in 1979 the two companies decided to merge their engineering talent and jointly settle on one design.

That’s when Immink got involved. The team at Philips, he says, “needed someone to do measurements of the two systems, the quality, how they coped with scratches, how they coped with imperfections of the disc. My job with the LaserDisc was finished, so I said, ‘Sure, I could do it.’ ”

Toward the end of the year, Sony sent engineer Hiroshi Ogawa over to Philips with a big box of electronics, Immink recalls. Ogawa hooked up his gear, Immink hooked up the Philips prototype, and the two, using experimental discs made with each company’s coding technologies, started their tests. They messed up the plastic discs with scratches and dust and, eventually, crammed more bits onto the discs to see how long they could extend playing time before the discs became unreadable. And then the two engineers packed up their gear, went to Tokyo, and repeated the experiments—because, Immink notes facetiously, “Of course, the rules of physics are completely different in Tokyo than in Eindhoven.” The whole process took several months.

Although Immink was acting as a test engineer, he was a researcher at heart, so he had his eye out for parts of the design that could be improved. And he found one: the coding scheme that specifies how bits of data are translated into physical marks on the disc.

To understand what he came up with, first visualize the shiny surface of an optical disc. Just under that polycarbonate surface is a reflective layer of metal, marked with a pattern of pits and “lands,” the places where it’s not pitted. The laser hitting that metal reflects from the pits and lands differently, creating a variation in the light’s intensity as it reflects back and hits an optical sensor. The system identifies a change in intensity as a 1; no change over a set distance represents a 0.

There’s a problem, though, when too many pits or lands are bunched close together, because the servo system—the electronic and mechanical controls for the optical head—relies on the trail of pits and lands to stay on track. (A CD doesn’t have grooves like a vinyl record to serve as a guide.) Immink explains this by referring to a classic fairy tale that goes by several names, among them “Little Thumb,” in which children turned out into the forest drop stones along the way to find their way home (a scenario also played out in “Hansel and Gretel”).

“If you do not drop a stone often enough, you lose your way,” Immink says of the path created by the pits and lands on the disc. The problem is exacerbated by dust or scratches that hide spots on the disc, like a fallen leaf hiding a pebble.

Both Philips and Sony had come up with different rules for translating digital audio data to sequences of pits and lands, rules that took these considerations into account. But Immink thought both approaches were investing too much disc real estate in their efforts to keep the servo system on track. Instead, he thought, by designing better control mechanisms for the servo itself, he could place a few less “stones” along the path it needed to follow. He also could reduce the number of bits that separated each 8-bit block of data bits—so-called merging bits—as long as he selected them carefully in relation to the data bits around them. These two adjustments would allow 30 percent more data to fit into the same physical space without causing the optical head to skip.

The encoding system Immink devised came to be called Eight-to-Fourteen Modulation (EFM). Using a lookup table, it translates each 8-bit chunk of data into a series of 14 bits, with every binary 1 separated by at least two but no more than ten 0s. This ensures that no sequence of pits and lands is too long (problematic because the transitions between a pit and a land generate a signal used for timing recovery) or too short (problematic because short sequences are difficult to detect and prone to error). Three merging bits separate each sequence, for a total of 17 bits to represent each 8-bit chunk of data. (The initial Sony-proposed code translated 8 bits to 24 bits.)

In mid-1980, Immink presented his approach to the joint Philips and Sony development group. He demonstrated, he says, that the coding technique would cooperate with the servo controller as effectively as previous versions.

Then, Immink recalls, “a Sony engineer who was one of the major decision makers for the project told me my design for the decoder that would translate the recovered 14 bits into the 8 user bits was too complicated. ‘Our design only requires five gates, and yours requires maybe 250 gates,’ he said. ‘If you can make it less than 70 gates—or maybe 100—then we will take it.’ ” Logic gates, at the time, were relatively costly.

Immink came back three weeks later with a version that contained only 52. “They had no choice but to accept it,” he says.

Later that year, Sony and Philips jointly published the Red Book, the document that set the standard for CD audio. It included Immink’s EFM technology. The first CD audio players hit the market in 1982, and by the early ’90s, CD sales surpassed those of both vinyl records and cassette tapes—before being supplanted by digital downloads in the past couple of years (exactly which year depends on how you do the counting).

The CD is by no means a dead format; more than 1.5 billion discs were sold in the United States alone in 2015, according to the Recording Industry Association of America. And the impact of Immink’s EFM code didn’t end with the CD. It went into the MiniDisc, introduced in 1992, with a slightly more compact version, EFMPlus, going into the DVD, which was introduced in 1995. It also went into the Super Audio CD, introduced in 1999.

After the launch of CD technology, Immink, who had taught himself coding theory on the job, decided to get a formal credential in the topic and submitted a series of research papers to Eindhoven University of Technology, earning a Ph.D. degree. Meanwhile, as it was the custom at Philips for all researchers to change groups every five years, he left optical recording and moved to magnetic recording, developing the coding technology for what became the Digital Compact Cassette format, introduced in 1992 to little success. In the mid-1990s, still in the magnetic recording group, he developed a coding scheme for the MultiMedia CD, a Sony/Philips invention that both companies later dropped in favor of the Toshiba-led effort to develop the now ubiquitous DVD.

Kees Schouhamer Immink

Current job: Visiting professor, Singapore University of Technology and Design

Date of birth: 18 December 1946

Birthplace: Rotterdam, Netherlands

Family: Married to Clazien Immink

Education: B.S. (1967), Rotterdam Polytechnic; M.S. (1974) and Ph.D. (1985), Eindhoven University of Technology

First job: Packing Mentos and other sweets for candymaker Perfetti Van Melle

First electronics job: Working on digital modems for the National Reserve Corps of the Royal Netherlands Army

Patents: Sixty U.S. patents, with related patents around the world

Hero: Michael Faraday

Most recent book read: Extreme Measures: The Dark Visions and Bright Ideas of Francis Galton, by Martin Brookes

First CD purchased: Brothers in Arms, by Dire Straits

Most recent CD purchased: Stardust, by Willie Nelson

Favorite musical artist: André Rieu and the Johann Strauss Orchestra

Leisure activity: Rowing (eight-person shell), bicycle touring

Car: Has never owned one

Major awards: IEEE Medal of Honor “for pioneering contributions to video, audio, and data recording technology, including compact disc, DVD, and Blu-ray”; IEEE Edison Medal; a Technology Emmy Award; Knight of the Order of Orange-Nassau, a civil and military Dutch order of chivalry

“My approach was 6 or 7 percent better in terms of storage capacity,” Immink recalls. “But it would again have required a redesign of the servo systems.”

Philips, along with its competitors, then turned its attention to the possibilities of a new kind of laser technology they expected would soon be available for commercial use: the blue laser. With a much shorter wavelength than the infrared lasers used in CD players and the red lasers used in DVD players, blue lasers would allow a dramatic increase in recording capacity, allowing high-resolution movies to be packed onto the same size disc as the CD and DVD.

Immink was not, however, assigned to this project, because he had rotated over to Philips’s telecommunications group, where he was working on modems. And in 1998 he left the company.

“The official reason I give is that I didn’t like it anymore. I just wanted to do something else,” he says.

For someone in the Netherlands, that was an unusual move, says A.J. Han Vinck, who was a professor at Eindhoven University when Immink applied for his Ph.D. “It is said that once you start at Philips, you die at Philips. So when he left at age 50, a very successful researcher, it was a big surprise.”

Generally, Vinck says, Immink does not do well accepting authority, recalling Immink’s initial unwillingness to make revisions to the manuscript submitted for his Ph.D. thesis. And, Vinck points out, the Dutch have a tendency to “push down” anyone who begins to appear even a bit better than those around him or her, which was likely affecting Immink.

And, Immink recalls, the labs at Philips, like those at many large companies around the world, had started changing, with less and less room for “unfettered research.”

“In the old days, the Philips research lab was an unregulated environment—good scientists and engineers got lots of freedom, and nice results came out of that,” recalls Jos Weber, an associate professor at the Delft University of Technology who has known Immink for decades and collaborates with him today. “When Philips restructured its labs to run more as a business unit, with specific targets, he was not happy.”

Immink’s employment agreement with Philips prevented him from working for a year; he spent most of that time working on a book. Meanwhile, efforts to develop blue-laser optical disc technology, now referred to as Blu-ray Disc, continued, with more and more companies signing onto a group effort, including Korean upstart LG. The coding scheme then on the table, but not yet approved, was a version of Immink’s EFM, called Enhanced EFM. Immink realized he had an idea for a different and better approach, one that started with 9 bits of data—not 8—before translating them into sequences of pits and lands. It was just a few percentage points better, he says, but it would allow more data to fit on a disc.

He filed patent applications for the technology, and then started working with a patent attorney to see about obtaining patents in at least the major markets. The process, he discovered to his dismay, would cost him hundreds of thousands of dollars and take years. And he’d have to file those applications within a year of having filed his application in the Netherlands.

On the advice of a Japanese friend, he contacted the Korean consumer electronics manufacturers, hoping to sell his work on the basis of the application and let the buyer complete the patent process.

The timing turned out to be perfect. LG, having just joined the group of companies defining the Blu-ray Disc format, wanted to submit a technology it owned for possible inclusion in the standard, but its team had nothing, Immink says. “At that moment, I knocked on their door with my technology, and they said, ‘We want to buy it.’ Just like that.”

The technology did not, in the end, make it into the Blu-ray standard. But the sale made Immink independently wealthy.

Since then, he’s stayed involved with research. Officially, he’s heading up his own company, Turing Machines. That business, created to manage his patents, now holds his investments in startup companies. He spends his time researching on his own or with faculty and graduate students at Delft University and at the Singapore University of Technology and Design (SUTD). His relationship with Delft University is informal; at SUTD he’s a visiting professor.

Immink’s research still focuses on the storage of digital data, but he’s turned from optical to solid-state drives as well as more far-out projects, like translating bits into DNA sequences for data archiving. “I love to come up with inventive methods to solve new problems,” he says.

SUTD associate professor Cai Kui is one of the people laying out those problems. Immink spends time in Singapore when it’s winter in Europe. During his stay, Kui says, “We meet three times a week, discussing new ideas. We’ll take a day in between to think about what we discussed and do individual work on it. Then we might hand off two ideas to Ph.D. students or postdocs to analyze and compare.

“Even at 70,” she says, “Immink continues doing hands-on research and can always come up with new ideas. His continued enthusiasm for doing research has inspired me.”

In the Netherlands, Immink bikes about 15 kilometers from his home in Rotterdam to Delft University, where he meets Weber about once a month. “He is very creative,” Weber says. “He’s still the one that comes up with the ideas.” The two regularly publish joint papers, which Immink drafts in the riverside studio he shares with his wife, an artist. Delft students seeking guidance sometimes visit him there.

When he’s not thinking about digital storage, he rows. Immink is part of a mixed-gender group that trains on eight-person sculls on the Rotte river. And he listens to music. His tastes are eclectic, running from Strauss waltzes to country and western—and, of course, he listens to it on CDs.

This article appears in the May 2017 print issue as “The Pit Boss.”