For years, the University of Toronto research team helmed by Edward H. Sargent has been setting the standards for the use of colloidal quantum dots—including setting conversion efficiency records in photovoltaics and pointing towards their use in infrared optoelectronics.

Now researchers from Sargent’s research team, led by Illan Kramer, have demonstrated that colloidal quantum dots (CQDs) can be sprayed onto a flexible film and used to coat just about anything.

“My dream is that one day you’ll have two technicians with Ghostbusters backpacks come to your house and spray your roof,” said Kramer, a post-doctoral fellow with Sargent’s group, in a press release.

The new process, which Kramer has dubbed “sprayLD,” a play on the term atomic layer deposition (ALD), lays a liquid containing the quantum dots directly onto flexible surfaces, such as film or plastic. The layer of CQDs is laid on in a roll-to-roll process not unlike how newspaper printing presses operate. This makes the process fairly easy to incorporate into other manufacturing methods, say the researchers.

In the research, which was published in the journals Advanced Materials and Applied Physics Letters, Kramer demonstrated that the resulting CQDs do not lose any of their energy conversion efficiency in the process.

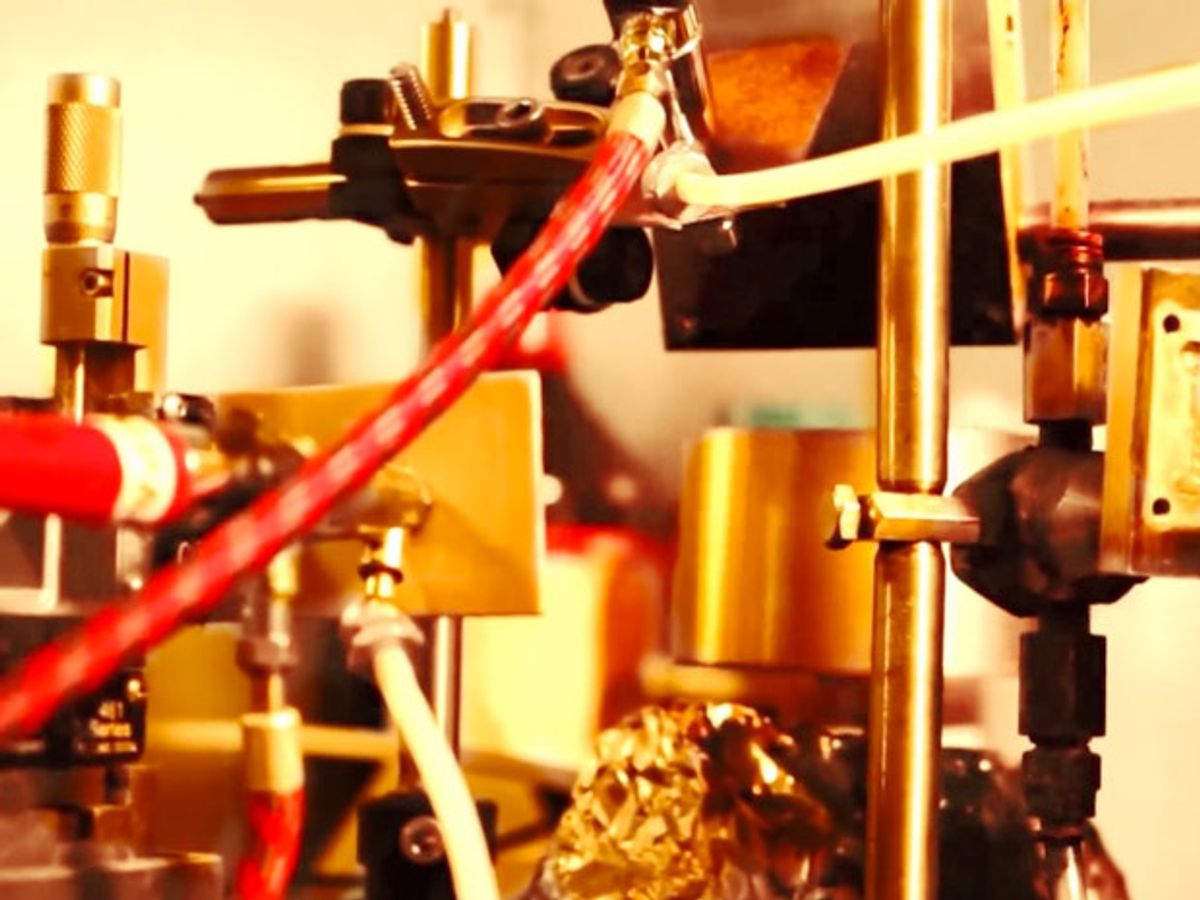

Prior to this research, the only way to get light-sensitive colloidal quantum dots onto a substrate involved batch processing, which is a chemical coating process that is comparatively slow and expensive. For this new roll-to-roll process, Kramer was able to fashion the deposition device out of a spray nozzle used in steel mills for cooling steel with a fine mist of water, plus a few regular airbrushes found in any art store.

“This is something you can build in a Junkyard Wars fashion, which is basically how we did it,” says Kramer. “We think of this as a no-compromise solution for shifting from batch processing to roll-to-roll.”

The device can be seen in operation in the video below.

Commenting on the research, Sargent said: “As quantum dot solar technology advances rapidly in performance, it’s important to determine how to scale them and make this new class of solar technologies manufacturable. We were thrilled when this attractively-manufacturable spray-coating process also led to superior performance devices showing improved control and purity.”

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.