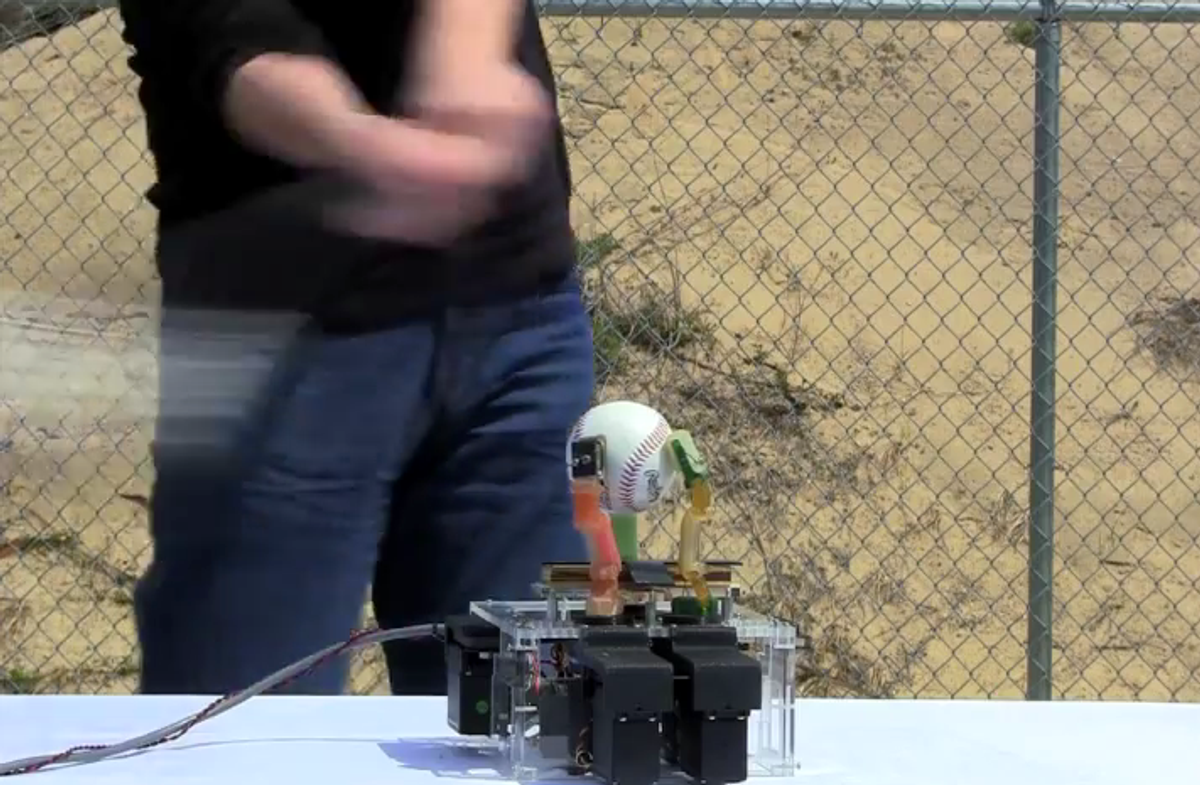

What's up with roboticists and baseball bats? Last year, German researchers showed off their tough new robot arm by smashing it with a bat. Not to be outdone, iRobot now turns to the same "stress test" technique to prove that its robot hand can take some serious punishment and come out unscathed. Watch:

iRobot built this hand as part of the DARPA Autonomous Robotic Manipulation (ARM) program. The model in the video is actually an early prototype. The current version will be attached to the DARPA ARM robot, which different research groups will use to develop and test new manipulation strategies.

What makes the iRobot hand different from other designs is that it is soft and compliant—and yet robust and dexterous. Traditional robot hands are rigid, so you need to control their position with great precision to grasp objects. Move the hand too much against a hard object like a table and you can break its joints and electronics. That doesn't happen with iRobot's hand. To pick up a credit card from a table, for example, the hand pushes its fingers against the table, forcing them to bend and grip the card.

"Our hand actually uses contact with the environment to manipulate various things," says Chris Jones, director for research advancement. "We leverage compliance, so we don't depend on expensive sensors to position the hand."

Because it's soft and compliant, the hand can also take hard blows without suffering damage. Jones explains that the fingers are made of soft, rubber-like polymers. The researchers get the shape they need by using molds, and while fabricating the fingers they embed tactile sensors and other electronics into the soft material. The actuation mechanism uses motors to pull cables inside the fingers. The cables are just standard fishing lines, Jones says, and if they snap you can easily replace them.

The iRobot hand is not only able to pick up small objects like a key, but it's also strong enough to hold a payload of up to 22.7 kilograms (50 pounds). Whether it's better than other robot hands such as the Barrett Hand, the Sandia Hand, Willow Garage's Velo Gripper, or the Robotiq Adaptive Gripper, among others, only time will tell, as the DARPA ARM and other research programs put these designs to the test, which we sure hope includes smashing them with bats.

Erico Guizzo is the Director of Digital Innovation at IEEE Spectrum, and cofounder of the IEEE Robots Guide, an award-winning interactive site about robotics. He oversees the operation, integration, and new feature development for all digital properties and platforms, including the Spectrum website, newsletters, CMS, editorial workflow systems, and analytics and AI tools. An IEEE Member, he is an electrical engineer by training and has a master’s degree in science writing from MIT.