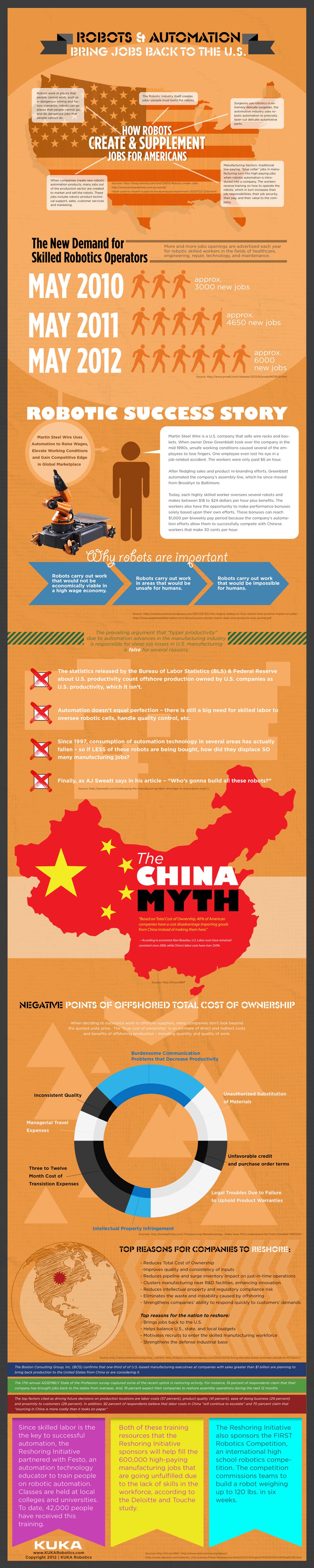

Kuka Robotics put together this nifty infographic describing how manufacturing robots aren't necessarily evil job stealin' machines of... evil. It's especially timely what with yesterday's big news about a certain robotics company that wants to use robots to make domestic manufacturing more cost effective and efficient, although Rethink is tackling things much differently than big boys like Kuka.

What Kuka's trying to sell you on here is medium to large scale industrial automation, involving robots in safety cages run by skilled operators. It's certainly true that automation of any kind can help a business that's making a lot of the same sort of thing, but for smaller businesses that do contract work, dedicated robots are rarely worth the massive up-front investment.

With Baxter, Rethink is trying to bring all of the benefits of having robots in the workplace to small businesses that haven't had access to this sort of technology before. It's not just that Baxter is (relatively) cheap at $22,000; but also that the robot can be easily programmed to do all kinds of different stuff by humans without any special operator training. So when Kuka talks about industrial robots creating jobs for humans with robotics skills, Rethink is sort of going in the opposite direction with robots that bring human skills to to a human workplace, creating jobs by making existing workers more efficient and lowering the cost of production to levels that are competitive with offshore manufacturing once you figure in the ugly side of trying to make something overseas.

We're certainly not saying that Rethink is somehow going about this in a better way than Kuka (or ABB or Adept or anyone else). Rather, Rethink is leveraging some unique technology to try to bring all of the benefits you'd find in the big business big robots world to the small business small robots world as well. Anyway, the infographic is below. You'll want to click on this image to make it nice and big and readable, otherwise you're in for a massive headache and probably an eyeball explosion or two.

[ Kuka ] via [ Robotland ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.