THE INSTITUTE Rejin Narayanan, an IEEE member from Kerala, India, was wondering how he could use his technical know-how to help fight the coronavirus pandemic. Talks with friends and colleagues quickly led Narayanan to form a volunteer group called Breath of Hope. Its 46 members have already produced seven simpler and affordable versions of existingmedical devices, including a non-invasive ventilator, an oxygenation device, and a portable intubation chamber.

Narayanan, a roboticist, is the founder of the startup Ingen Robotics, also in Kerala. He is also a member of the IEEE Robotics and Automation Society.

“Breath of Hope started as a discussion I had with my friend and IEEE Member Dr. Praveen Pai, [of the Kerala State AIDS Control Society] on what we could do to fight COVID-19,” Narayanan says.

We started talking about a basic respirator apparatus, and it became our first project,” he says. “Soon our friends and their friends joined, and we started working on multiple projects.

“Our volunteers come from diverse professional backgrounds including doctors, engineers from multiple disciplines, lawyers, and social workers—all of us contributing to the fight against COVID-19.”

In addition to Narayanan, there are 15 members from the IEEE Kerala Section who volunteer for Breath of Hope. The section’s five past chairs are also members of the project’s strategy group.

The Breath of Hope team began developing a low-cost ventilator design to address the dire shortage of the machines in developing countries such as India, but Narayanan says the initiative soon expanded to address other problems faced by doctors and healthcare professionals. These include the lack of medical equipment such as oxygenation devices, personal protective equipment, intubation boxes, and safe ways to collect samples.

Narayanan says the group uses digital fabrication techniques like 3D printing and laser cutting in addition to traditional methods such as milling and turning. It also uses Arduino boards for prototyping, and computational fluid dynamics simulations to improve the designs. The team has also made use of the Kochi Fablab, established by the Kerala Startup Mission, and facilities at the ICFOSS [International Centre for Free and Open Source Software], both run by the state government of Kerala.

Because of the nationwide lockdown imposed in India, he says they used locally available components and facilities.

“Most importantly, we decided to adopt the open-source model to ensure that these designs are available for anybody around the world to use, modify, and contribute back to the community,” Narayanan says.

The Institute asked Narayanan to explain how each device works and its status.

An Automated Resuscitator: The RespiratorApparatus

Ventilators are expensive and in short supply the world over. In this situation, the quickest and most widely used solution was to automate BVMs (bag valve masks). [To deliver air to a patient, BVM's are typically hand-pumped.] The RespiratorApparatus does this by using a simple mechanism: wiper motors used in cars. The prototype runs on an Arduino, and uses sensors to determine precisely the position of the arm that presses the Ambu bag.

Unlike manual pumping of BVMs used by paramedical staff, electronic circuits and software in the RespiratorApparatus allow a good amount of control, so doctors can set an approximate tidal volume [the volume of air entering and exiting the lungs after each breath], breaths per minute, and I:E ratio that is right for the patient. [This ratio of the duration of inspiratory and expiratory phases.]

We have a prototype of the product ready and are working on an improved version with pressure and flow sensors for better results.

Oxygen Supply: The HopeFlo

HopeFlo is a high-flow nasal cannula (HFNC) system that can be used to treat COVID patients. HFNC systems available in India are quite expensive and to fight a pandemic like COVID-19, we need a large number of inexpensive devices, even if only basic features are available. This is why we set out to build an affordable HFNC system.

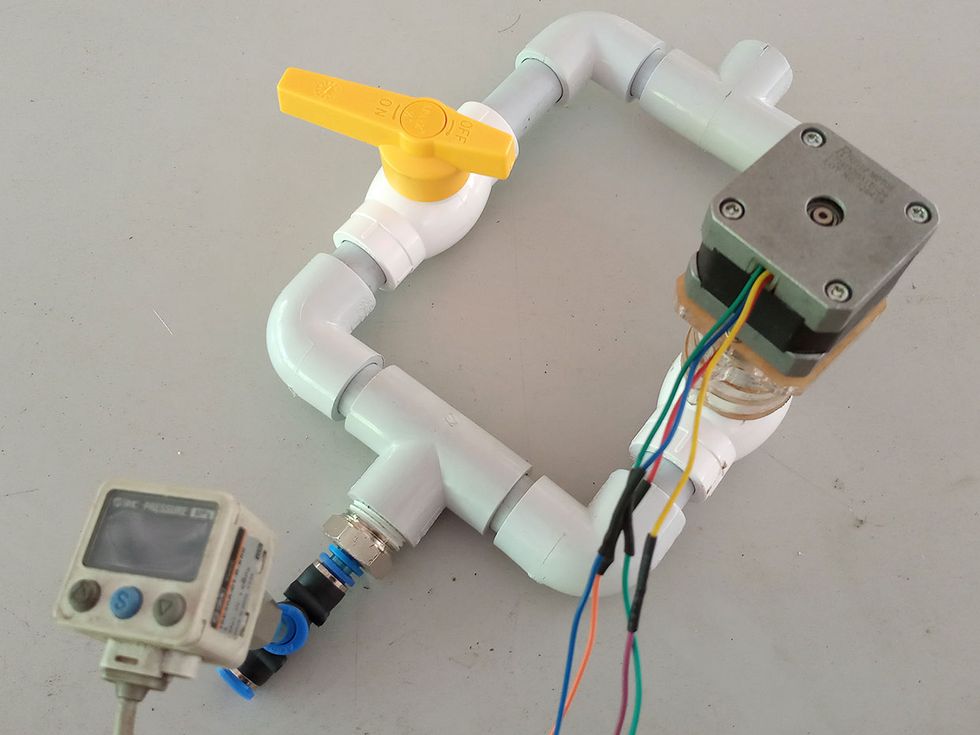

At the heart of the system is a simple air-oxygen proportioning and blending mechanism to control two parameters: the percentage of oxygen and the flow rate.

This system can be connected to air and oxygen lines in a hospital, and used for non-invasive ventilation. Once the oxygen-air mixture is ready, it is humidified and slightly heated to maximize patient comfort. This mixture is then fed to the patient through a nasal cannula.

We use custom electronics to control the valves using stepper motors. There is a basic pressure feedback loop, which makes sure that the system is working correctly.

We have completed the design and prototyping of the proportioning and blending system. Limited tests have been done successfully. We need to add off-the-shelf components and build electronics to complete the system.

Procedure Protection: The Portable Intubation Chamber

Intubation procedures release aerosols into the air, which pose a health hazard for medical professionals. The intubation box is placed over the head of the patient, allowing the doctor to perform procedures through openings on the box. The system continuously pumps out air from inside the intubation box during medical procedures, then filters it using the HEPA filter. We have also made an optional UV filter to augment the HEPA filter.

Using the same technologies used for the PIC, we have also made a HEPA filter for closed, air-conditioned spaces. This will reduce chances of infection in offices, buses, and trains. The system currently works on 12V DC.We have successfully built the first version, and have done tests to prove that it works.

Sample Handling: SafeCollect

Collection of samples and managing related tasks in COVID-19 testing is a challenging task. Medical personnel must be protected, and the samples need to be refrigerated until they can be taken to the nearest testing center, which—in the developing world—can be far away.

The vehicle features modifications to make sure that outside air enters the cabin space only through a powered air filter. Sitting inside the vehicle, medical personnel can collect samples through a special opening that contains safety gloves. There is also a specially made box in the vehicle that contains all the necessary medical instruments needed, including a digital stethoscope. At the same time there is a specially made cavity for this box that segregates it from the cabin in an airtight manner.

The sample storage system is designed to cool the sample quickly, maintain a low temperature for an extended period of time, and provide a strong and safe enclosure to avoid cross contamination.

We have already rolled out one such modified vehicle in the district of Alleppey, and we are improving the storage system.

Personal Air-Filtering Protection: HoodofHope

HoodofHope augments regular personal protective equipment (PPE) with special headgear that uses a polypropylene filter medium to keep out aerosols. This greatly reduces the chances of infection by medical professionals exposed to dangerous levels of virus-laden aerosols for long durations while treating COVID-19 patients.

Air is forced in through a filter via a fan and pumped out through a second filter so that in case the wearer is infected, it is not passed on to others. We also integrated an off-the-shelf Bluetooth-enabled stethoscope to enable the doctor to auscultate [examine a patient by listening to sounds from a stethoscope] the patient while wearing the hood.

The HoodofHope uses a rechargeable power bank as the power source. We use DC to DC converters to power the fans.

We have done a first trial of the HoodofHope, and received encouraging feedback from doctors. Apparently, in tropical climates, the HoodofHope makes it a lot more comfortable for doctors who wear PPE.

The initial prototypes have been made and tested by doctors. Tooling has been completed, and we are preparing for volume production.

Low-cost Face Covering: ShieldofHope

ShieldofHope is a face shield for public-facing personnel to protect them from infectious droplets. This low-cost face shield uses transparency sheets as the barrier and two adjustable straps to achieve the right fit for the head. Our unique advantage is a support on top of the shield that eliminates the need to constantly adjust it. No porous materials are used so the shield can be washed and reused.

We have started mass production of the ShieldofHope, and more than 10,000 shields are already in use. This project has received recognition on social media from Kerala’s finance minister. Airline personnel used this shield in the Vande Bharat mission to evacuate Indians from the Middle East due to the COVID-19 situation.

The HoodofHope and the ShieldofHope projects together received a “Nidhi Prayas” grant of a 1,000,000 Rupees (approximately US $13,000) through TIMed, a biomedical device incubator in the city of Thiruvananthapuram. This grant is supported by [India’s] Department of Science and Technology.

Decontamination Chamber: Door of Life

Door of Lifeis a portable sanitizing room for healthcare professionals who come in close contact with COVID-19 patients. It consists of three cabins. The first one is for removing the contaminated clothes, the second is to disinfect the body, and the third cabin is for changing into clean clothes.

The room will be made with a combination of plastic and galvanized iron sheets. The design is compact to install in a small space (12 feet by 4 feet) including entry and exit ways on the ground. It also includes essential filters for air and water to prevent contamination. The room also requires an electrical connection and continuous water supply.

The idea is to make it into a kit form so that several such kits can be easily transported and installed at medical facilities formed during emergencies.

Users will have a choice of cleansing methods. Once the choice is made, the intelligent controls, along with audio visual indications, will guide the user from start to finish. At the end of the process, the user can change into fresh, non-contaminated clothes— carrying their disinfected clothing in a bag, ready for washing safely at home.

The concept design is ready and partial prototyping has also been done. We are working on the design of the production version.

“We welcome engineers from across the globe to contribute to our projects,” Narayanan says. “Many of our projects can benefit from simulations and design optimizations, so it is possible to contribute remotely even though our projects are mostly hardware. Members who are interested in helping can email me.

Attention IEEE members: are you part of a team responding to the COVID-19 crisis? We want to hear from you! Wherever you are and whatever you are doing, if you are helping deal with the outbreak in some way, let us know. Send us accounts of anywhere from 200 to 800 words, or simply give us a rough idea of what you are doing and your contact information. Write to: k.pretz@ieee.org