IceCube: The Polar Particle Hunter

Searching Antarctica for the frozen paths of cosmic-ray neutrinos

No commercial airline flies to the South Pole. Instead, I started my trip there on a U.S. Air Force C-17 transport, which traveled from Christchurch, New Zealand, to McMurdo Station, a U.S. Antarctic research center located on the southern tip of Ross Island. I stayed at McMurdo overnight before boarding a smaller plane, an LC-130 turboprop, for the rest of the journey. After a 3-hour flight over the Transantarctic Mountains, my plane landed on skis at the bottom of the world.

Stepping off the LC-130, I found the cold, thin air a real shock—the South Pole is more than 2800 meters above sea level, and the temperature was –30 °C. I staggered to the shelter of South Pole Station, from which, after suiting up in 10 kilograms of extreme-cold-weather gear, I walked to the nearby drilling camp. The goal of this operation was to bore holes 60 centimeters in diameter, each reaching about 2.5 kilometers below the surface, which is deeper than the Grand Canyon.

In 2005, a year before my visit, technicians had drilled the first of 86 holes. Initially, each one took 57 hours to make, using a jet of hot, pressurized water. By the time I arrived, the drillers had honed their technique, and the same task took 40 hours of work, weather and equipment permitting.

On the morning of 18 December 2010, the drill burrowed into the ice one final time to complete the last hole. These holes are now the permanent homes for strings of exquisitely sensitive light detectors, which more than 200 scientists, engineers, and technicians from nearly 40 institutions—including my own, Lawrence Berkeley National Laboratory (LBNL)—will use to search for signals from the far reaches of the cosmos.

We hope to solve a mystery that came to light 100 years ago, when Victor Hess, a physicist at the Institute for Radium Research of the Austrian Academy of Sciences, climbed into a hot air balloon. He wanted to measure radiation at high altitudes. Scientists had discovered this radiation—what physicists now understand to be a sporadic flittering of subatomic particles—almost everywhere they looked. Some attributed it to radioactive elements in the ground, and Hess wanted to test that theory. He took off into the air, eventually ascending 5000 meters. As Hess climbed, he saw an increase in the radiation he was measuring. That meant it wasn’t coming from Earth. Nighttime readings were no lower, which ruled out the sun. He concluded that the origin was likely somewhere deep in space. Hess’s discovery of what were later dubbed cosmic rays won him a Nobel Prize in Physics, in 1936. Although Hess’s work encouraged researchers to focus on the heavens, he was unable to determine the exact source of these energetic particles. Today astronomers and physicists still debate the possibilities.

Very likely, some of these cosmic rays originate within our own galaxy, accelerated in the magnetic fields and dense plasma that stars produce when they reach the end of their lives and explode, forming black holes or neutron stars. More energetic cosmic rays probably have more violent births, within jets spewed from the disks of matter surrounding ultramassive black holes at the center of other galaxies; during the collapse of a giant star, 100 or more times as massive as our sun; or in a collision between two black holes or between a black hole and a neutron star.

Scientists can easily detect the charged particles in cosmic rays using any number of simple detectors—even photographic film. And they have: By the 1930s, physicists had measured coincident signals using instruments separated by hundreds of meters. They realized that the background radiation that perplexed scientists of Hess’s time could come from high-energy, charged cosmic-ray particles that strike nitrogen or oxygen atoms in Earth’s atmosphere and create in each collision a shower of low-energy particles. By the 1960s, they knew that these downpours could include billions of particles, spread over many square kilometers. But figuring out the starting point of the original cosmic ray requires a more sophisticated approach. Any matter or magnetic field that a charged particle encounters during its interstellar journey alters its trajectory, making it hard to determine its origin.

But cosmic rays also contain uncharged particles called neutrinos, which travel more determinedly. Magnetic fields don’t affect them, and they barely interact with matter, meaning that they can course unhindered through the thickest clouds of cosmic dust and gas. Because the path of a cosmic-ray neutrino points straight back to its origin, astrophysicists dearly want to trace the trajectories of these particles.

Unfortunately, the same characteristic that allows neutrinos to travel with little interference makes them nearly impossible to detect. Only very rarely will one crash into matter and create a cascade of other, more easily detectable charged particles. To witness that, researchers must be either extremely lucky or need to monitor a big target—for example, a 1-cubic-kilometer chunk of Antarctic ice.

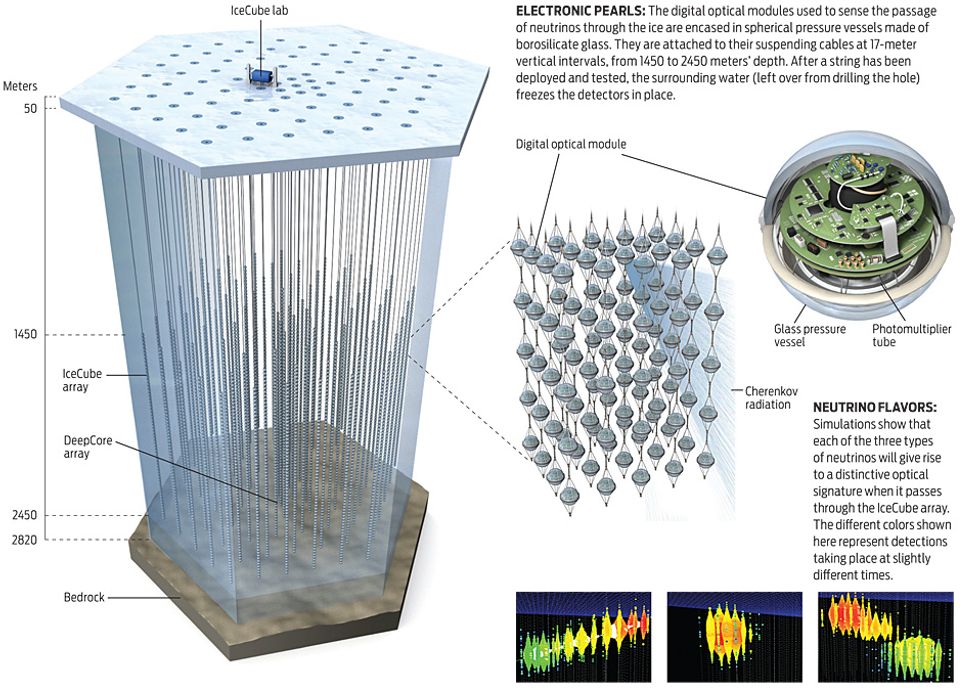

My colleagues and I have transformed this great volume of Antarctic ice into a particle detector we call the IceCube Neutrino Observatory. With it, we can look for the aftermath of collisions between neutrinos and atoms, which, rare as they are, create fast-moving charged particles. If these particles move quickly enough, they give off the electromagnetic equivalent of a sonic boom, a bluish glow called Cherenkov radiation. Buried in Antarctica’s transparent ice, sensitive light detectors look for that glow, which they can spot at considerable distances. From this signal, we can calculate the original neutrino’s path.

IceCube isn’t the first detector of this kind. Physicists began work on its predecessor, the Antarctic Muon And Neutrino Detector Array, or AMANDA, in the early 1990s. It used ice-entombed photomultiplier tubes to turn the faint flashes of Cherenkov light into electrical impulses. Coaxial cables provided the high voltages needed to run these tubes while also carrying analog signals upward to the surface. But the first measurements quickly revealed a nasty surprise: The ice around the detectors contained tiny air bubbles, which scattered much of the Cherenkov light before it could travel a mere 50 cm.

The solution, AMANDA scientists determined, was to dig deeper. Below 1400 meters’ depth, the weight of the ice above squeezes these bubbles out of existence. By 1996, researchers had buried 10 strings of optical sensors up to 2500 meters below the surface. With those strings, the team observed their first neutrinos. By 2000, AMANDA was fully operational, with 677 detectors festooned on 19 separate strings. The good news: The array detected about 1000 neutrinos every year until the project ended in 2009. The bad news: As far as AMANDA scientists could tell, none of those observations had anything to do with neutrinos arriving from the far reaches of the cosmos. All of the neutrinos they detected had formed when charged cosmic-ray particles hit gas molecules in the atmosphere, a commonplace occurrence, which wasn’t particularly helpful in tracking down the rays’ origins.

IceCube will face the same challenges. But it has a key advantage over AMANDA—it’s about 100 times as big. More volume means more space to track the charged particles born when neutrinos wallop the ice. That’s key for helping the IceCube team to determine the types of neutrinos that we spot. Neutrinos come in three varieties, and we expect that extraterrestrial sources should give rise to an equal number of each type, whereas something as mundane as a cosmic-ray air shower produces a decidedly lopsided distribution of the three neutrino flavors.

But IceCube’s greater size isn’t its only advantage over its predecessor. Over nine years, successive generations of AMANDA strings used different hardware to send analog signals to the surface—first coaxial cables, then twisted pairs, and finally optical fibers. Each of these approaches required a different type of data transmission, which made it hard to operate them in concert, demanded laborious calibrations, and still provided a very limited dynamic range. To avoid these problems, IceCube’s designers decided to place the signal-processing electronics within the optical detectors themselves and to send only digital data back up the cables.

Slightly larger than a basketball, each module holds a photomultiplier tube for sensing Cherenkov radiation and a precision clock in the form of a quartz crystal oscillator, along with electronics for data acquisition, signal processing, and telemetry, all tightly packed inside a spherical pressure vessel made of borosilicate glass.

To convert an analog signal into a digital one, the onboard electronics must sample the output of the photomultiplier tube 300 million times per second while using less power than any available commercial converter. IceCube’s modules rely on two custom-made waveform-digitizer chips, which operate in a “ping-pong” fashion—while one is busy digitizing, the other is ready to receive new signals. Both chips contain four sets of 128 capacitors connected to four sets of 128 field-effect transistor switches. When the analog signal reaches these capacitor arrays, the switches close in rapid succession, allowing each capacitor to sample the incoming voltage for 3.3 nanoseconds. A slow, low-power converter can then digitize those analog samples. With this setup, each of the two chips consumes a paltry 30 milliwatts of power.

A logic chip called a field-programmable gate array, or FPGA, starts this system running and orchestrates its operation. This programmable chip allows us to update the hardware configuration from the surface, but that comes with an inherent danger: A bad command could terminate all communication with the module. To avoid that possibility, the FPGA boots from an unalterable, 1-megabyte one-time-programmable memory that includes the code for vital communication systems. We can then safely reprogram a separate 8-MB flash memory when we need to update the system.

Designing these modules was no easy feat. Each has to function reliably from room temperature down to –55 °C. The modules also have to withstand pressures that can reach up to 70 megapascals (almost 700 times sea-level atmospheric pressure) from the frozen water above. Each module also has to use less than 5 watts of power. That might seem overly strict rationing, but remember—the observatory has to generate this electricity locally, and the nearest gas station is 1400 km away. Five watts per module corresponds to about 10 planeloads of fuel each year to run the entire array.

My colleagues at LBNL helped to design instrument modules that could meet these demanding requirements. Those efforts began in 2000, when they built the electronics for a prototype string of detectors, which provided both an analog output and a digital data stream containing the results of the internal signal processing. The AMANDA team deployed that primitive digital string, and it worked well. Soon after, the U.S. National Science Foundation approved the construction of the IceCube observatory, in part because the prototype string demonstrated its feasibility.

The original IceCube design called for 4800 digital optical modules, attached to 80 vertical strings set into the ice with a horizontal spacing of 125 meters. One module is positioned every 17 meters along each string between 1450 and 2450 meters’ depth. The IceCube collaboration has also developed an extension called DeepCore, which has six more strings in holes drilled with a smaller (72-meter) horizontal spacing. DeepCore will help us to detect lower-energy neutrinos. Deploying these 86 strings has taken six construction seasons, because each hole requires almost two days to drill, and installing the string usually takes another 12 to 15 hours.

During my first visit to the South Pole in 2006, I had the chance to help out with the installation of one string. There were about eight of us on the crew, and everyone had designated jobs: prepping the modules, attaching them to the cable, measuring the distance between them using a laser range finder, and running the winch. After we had attached and lowered all 60 modules into the ice, the winch operator rolled out the last 1400 meters of cable, which took nearly an hour. Looking into the open hole, it’s hard to appreciate the depth—after about 30 meters, you see only darkness.

Descending into this particular heart of darkness would indeed be like going back in time, because the ice stores a record of prevailing conditions when the snow that formed it first fell. The deepest modules touch snowfall from 100 000 years ago. Some of the intervening layers of ice contain appreciable amounts of dust—including vestiges of the ash that ancient volcanoes shot into the air. Because that dust absorbs some of the faint light we monitor, our team needed to map it carefully by temporarily lowering an instrument called a dust logger into the freshly drilled holes. A laser probe in the logger shines a thin, pancakelike beam of light into the ice around the hole, and a detector mounted below measures the amount scattered backward.

Whenever a photon hits one of the modules’ photomultipliers—hemispherical vacuum tubes 25 cm in diameter—the tube’s photocathode emits a single electron. A potential of a few hundred volts accelerates this electron until it strikes a plate within the tube with enough energy to eject up to 10 additional electrons. Like pebbles in an avalanche, these in turn accelerate and strike a third plate, producing yet more electrons. After 10 such amplifications, you’ll have something like 10 million electrons.

After figuring out how to convert that analog signal into a digital one, we had to grapple with how the module should filter the data before sending them to the computer-filled “counting house” at the surface. When it detects a photon, each module waits for signals from the two neighboring modules above and below on the string indicating whether they, too, have registered hits. For isolated events, the module records only a brief summary. But when an adjacent module also senses Cherenkov radiation, they both record a complete set of measurements to transmit to the surface, where computers filter the data again and begin analysis, sending more interesting neutrino recordings by satellite to a data warehouse at the University of Wisconsin–Madison.

Even before all of IceCube’s strings were in place, modules were already transmitting data, and the transfer rate has only grown over time. In 2008, the array sent north 32 gigabytes per day; in 2011, we expect to transfer 88 GB per day, or about 32 terabytes per year.

Despite the complexity of this system and the demanding environment it must withstand, IceCube is performing very well. Ninety-eight percent of the deployed modules are working perfectly, a track record better than that of many space-satellite designs. As the data mount, we should soon be able to identify neutrinos from cosmic sources. However, the most energetic neutrinos, those with energies above 1017 electron-volts, are extremely rare and so will require still bigger detectors. By normal standards, 1017 electron-volts isn’t much energy—barely enough to lift an apple about a centimeter—but it’s a colossal amount for a subatomic particle. To detect these very rare particles, we will likely need a block of ice 100 times as large as IceCube. Antarctica has no shortage of ice, so that’s not a problem, but outfitting this volume with a dense array of optical detectors would be prohibitively expensive.

Some researchers plan to use a different approach to monitor such particles. Instead of searching for visible Cherenkov light, which fades greatly within 200 meters, they intend to detect Cherenkov radio waves. When a highly energetic neutrino collides with the ice, it creates many charged particles, and the collective interactions of these particles with the ice in turn produce radio waves. The more energy the neutrino has, the stronger the waves will be. And because radio waves can travel up to 1000 meters within ice before fading significantly, the detector will need relatively few detector modules to cover the required 100-cubic-kilometer volume.

Researchers could perform such an experiment at various Antarctic locales, including the South Pole and the 570-meter-thick Ross Ice Shelf. The South Pole offers thicker and less absorptive ice, but the Ross Ice Shelf sits atop the Ross Sea, which acts as a near-perfect radio mirror, increasing the signal at the surface. In December 2009, I returned to Antarctica to deploy a prototype station for a neutrino detector that would take advantage of this effect. We call the project ARIANNA, which stands (loosely) for Antarctic Ross Ice-shelf Antenna Neutrino Array. It will use downward-facing radio antennas buried in shallow holes. A few of the neutrinos that enter the ice will generate radio waves when they strike atoms within it. The neutrinos that rain downward will be the easiest to sense, because they produce radio waves that also travel downward—but only until they hit the conductive seawater below. At that point, they bounce right back. This phenomenon allows us to pick up their signals in the near-surface antennas. If the prototype we worked on is successful, it may usher in a full-scale neutrino detector containing 900 radio antennas spread over a square patch of ice 30 km on a side. That’s an awful lot of stations, but because these antennas sit on the surface, they are relatively quick and simple to put in.

One hundred kilometers south of McMurdo Station, the Ross Ice Shelf has neither runway nor ski-way, so my colleagues and I had to set out by helicopter for our ARIANNA experiments. Our three-person field team originally planned to spend nine days camping on the ice, installing and testing our equipment. On day nine, however, it was snowing at McMurdo, so the helicopter couldn’t fly. The next day, clouds over Minna Bluff, which separates McMurdo from the ice shelf, again prevented the helicopter from reaching us. We finally got out on day 11, relieved.

But we had little cause to complain. Our tiny particle quarry traveled much farther, from places yet unknown, with many more obstacles in their way. And before the Antarctic sun set, we made it back to warm homes and offices, while the neutrinos continued to forge paths through the ice all winter, creating tiny glimmers of light within the frozen darkness.

This article originally appeared in print as “The Polar Particle Hunter.”

About the Author

Spencer Klein, a senior scientist in the Nuclear Science Division at Lawrence Berkeley National Laboratory, has traveled to Antarctica twice in the name of neutrino astronomy. The second time he camped for 11 days on the Ross Ice Shelf at an isolated spot 30 kilometers off the continent’s shore. “The air was so clear,” he says, “that it seemed you could see forever.”