Over the past few years I’ve designed a number of radon detectors; building them is an opportunity to work on multidisciplinary projects with a social benefit. Worldwide, naturally occurring radioactive radon gas seeps from rocks and soils, where it can accumulate in buildings at hazardous levels. The World Health Organization estimates that as many as 14 percent of lung cancers are due to radon exposure. In my work at Carleton University, in Canada, I’ve used custom integrated circuits and specially programmed microcontrollers for my designs, but recently I wondered how I could make a detector with spare parts lying around my basement.

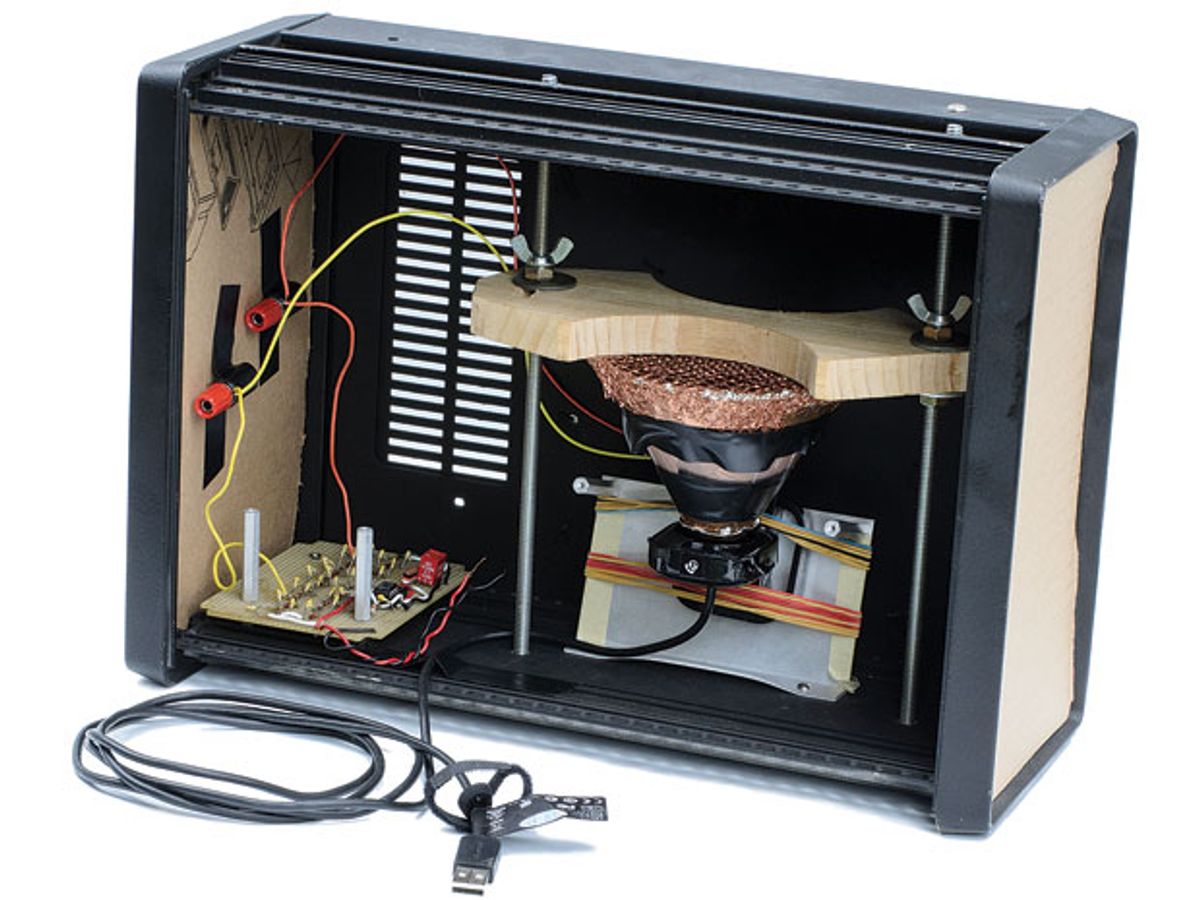

It turns out that you can make a cheap and effective radon detector with five basic elements: a webcam, a funnel covered with copper tape and mesh, a voltage multiplier built from some basic electrical components, a box, and a computer.

The system works because radon and some of its daughter products emit alpha particles as they decay. These alpha particles are responsible for most of the damage to human tissue that occurs when radon gas is inhaled, but they will also produce a slew of electron-hole pairs that show up as illuminated pixels should they strike the CMOS image sensor chip that’s at the heart of many webcams.

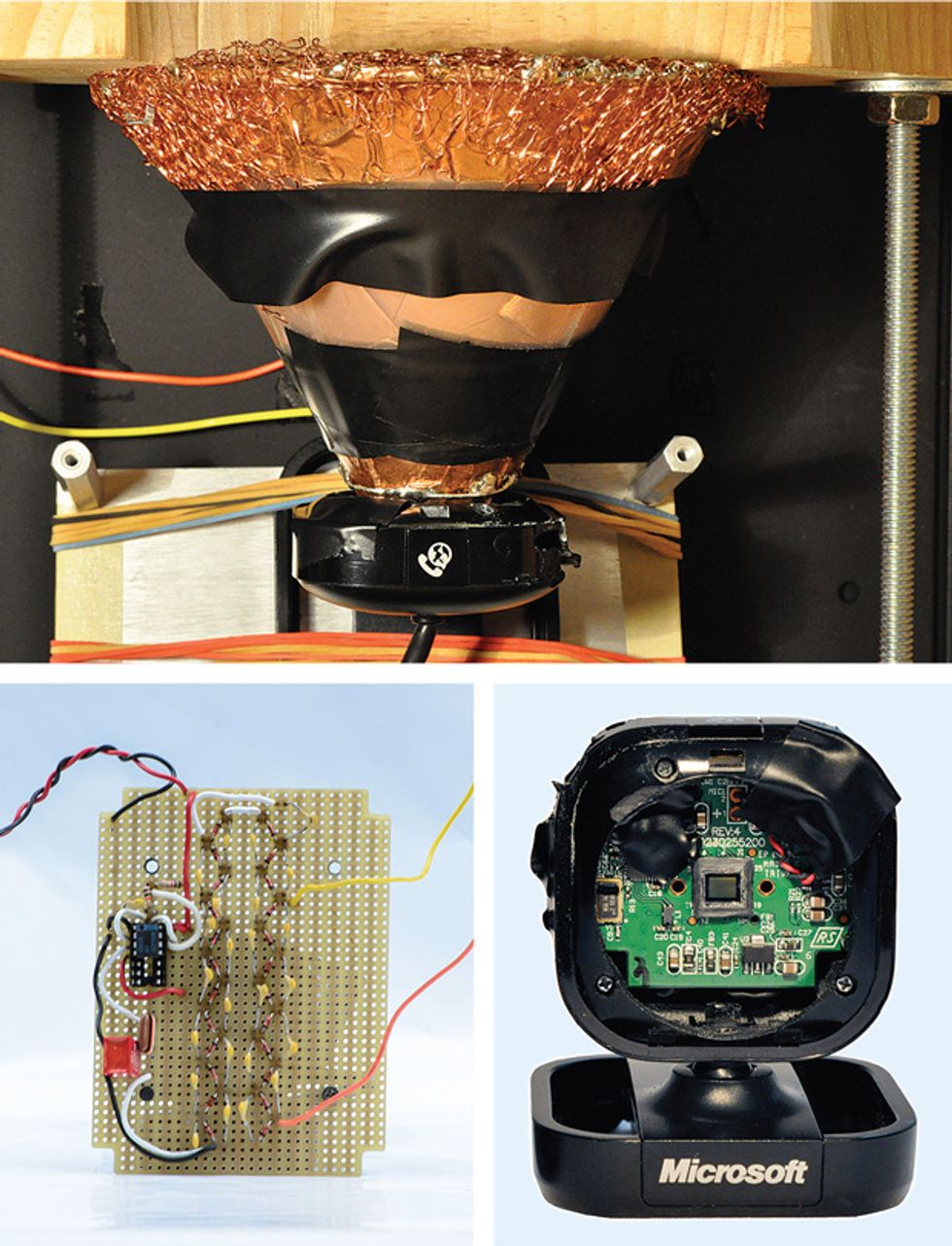

As alpha particles don’t travel very far through solid matter, it’s necessary to cut away the protective cover over the webcam’s image sensor. Starting with a spare Microsoft LifeCam VX-2000 webcam (about US $20 to $30 online), I cut away the protective cover using a Dremel tool and covered the indicator LED with electrical tape.

Putting the modified webcam into a dark, ventilated box and connecting it to a computer via a USB connection gave me a working—but very slow—radon detector. In order to make it more sensitive, I added an electrostatic concentrator to capture one of radon’s alpha-particle-emitting daughter products.

When radon decays into polonium-218, the polonium is usually left with a positive charge, so it can be swept toward the webcam’s image sensor with a suitably shaped electric field. Some copper tape (VentureTape 1626) and a powder funnel (I happened to have a Nalgene 4252-0100 powder funnel on hand) is all you need to make a two-electrode electrostatic concentrator that creates a field of the right shape. I applied the copper tape to the interior of the funnel, making sure to preserve electrical contact for both electrodes. I used a bottom electrode size and spacing of 15 millimeters. I then stretched copper mesh over the top, soldered a few spots into position, and I was done.

To get an idea of how the concentrator would behave and how strong a field I would need to generate, I modeled it using Comsol’s multiphysics simulation software. For a concentrator 10 centimeters high, I estimated that an electric field strength of 50 volts per meter would suffice for collecting charged polonium-218. Although high voltages are required at the concentrator’s electrodes to create this field, they aren’t that hard to generate because, effectively, no current will be drawn between the electrodes.

I put together a 12-stage Cockcroft-Walton voltage multiplier driven by a bipolar 555 timer feeding a Triad Magnetics SP-4 audio transformer. The multiplier converted a 15-V supply to the 1370 V and 990 V I needed for the upper and lower concentrator electrodes, respectively. Although you should be careful dealing with voltages as high as these, the voltage multiplier supplies so little current that an accidental contact shouldn’t be lethal. I also used small (1 nanofarad) capacitors to avoid a dangerous buildup of charge. But again, be careful, and proceed at your own risk. Turning on the high-voltage concentrator improved the count rate of the detector by 25 times or more. Not bad for an old funnel and copper tape!

I used Matlab software to control the webcam and also analyze the data. As the image sensor can potentially also detect less strongly interacting beta particles, I set the detection threshold, over which a pixel is considered to have been struck by an alpha, high enough to avoid noise and beta impacts. Also, when the sensor is struck by an alpha particle, an entire cluster of adjacent pixels will often register the impact, so it’s necessary to identify any clusters to avoid overcounting strikes. I used an 8-nearest-neighbor algorithm to find clusters. In all, it took about 100 lines of code.

Calibrated with a Safety Siren Pro Series3 radon detector (about $130), my system counted 5.2 alpha strikes per hour in an ambient radon concentration of 159 becquerels per cubic meter. At this level of sensitivity it would take the detector about 20 hours to determine whether radon was present at levels recommended as actionable by the U.S. Environmental Protection Agency with about 10 percent accuracy.

(For the future of this detector, I am thinking of using electrostatics-modeling software to optimize the concentrator shape, electrode size, and voltage to make an even more efficient detector. It would also be interesting to rigorously calibrate the detector and observe activity dependencies on temperature, humidity, and the presence of airborne particulates.)

If you build a similar detector yourself and start reading high counts, contact a professional (or buy a calibrated detector). It might be time for radon mitigation in your own home.

This article originally appeared in print as “DIY Radon Detector.”