How E Ink Developed Full-Color e-Paper

The road to color e-paper took two decades

Editor’s note: Apple is said to be testing color e-paper displays from E Ink for the iPhone, according to recent reports. It’s a promising step for E Ink’s two-decade-long campaign to bring full-color e-paper into the world. To learn more about E Ink’s technology, read our feature by E-Ink scientists Edzer Huitema and Ian French below.

It was the end of 2008, October, right before the holiday shopping season. Talk-show host Oprah Winfrey released her highly anticipated Favorite Things list, with the Amazon Kindle topping the gadget category.

This is the moment that the concept of electronic paper, or e-paper, went mainstream.

But this black-and-white, reflective display that always appeared to be on was invented well before the Amazon Kindle made it famous. Its story began a decade earlier, in 1997, at the MIT Media Lab, when it was created by two students, J.D. Albert and Barrett Comiskey, who were inspired by their professor Joseph Jacobson.

From the very beginning, e-paper seemed magical. It was easy on the eyes, even outdoors and in bright sunlight, where other portable displays became unreadable. It could go weeks between charges while mobiles equipped with other displays barely made it through a day (some of them still barely make it through a day). Yet its limitation was obvious—images could appear only in black and white. In a world that hadn’t seen a monochrome display in a very long time—TVs made the switch in the 1960s, computer monitors in the late ’80s—a monochrome display was definitely quaintly old school.

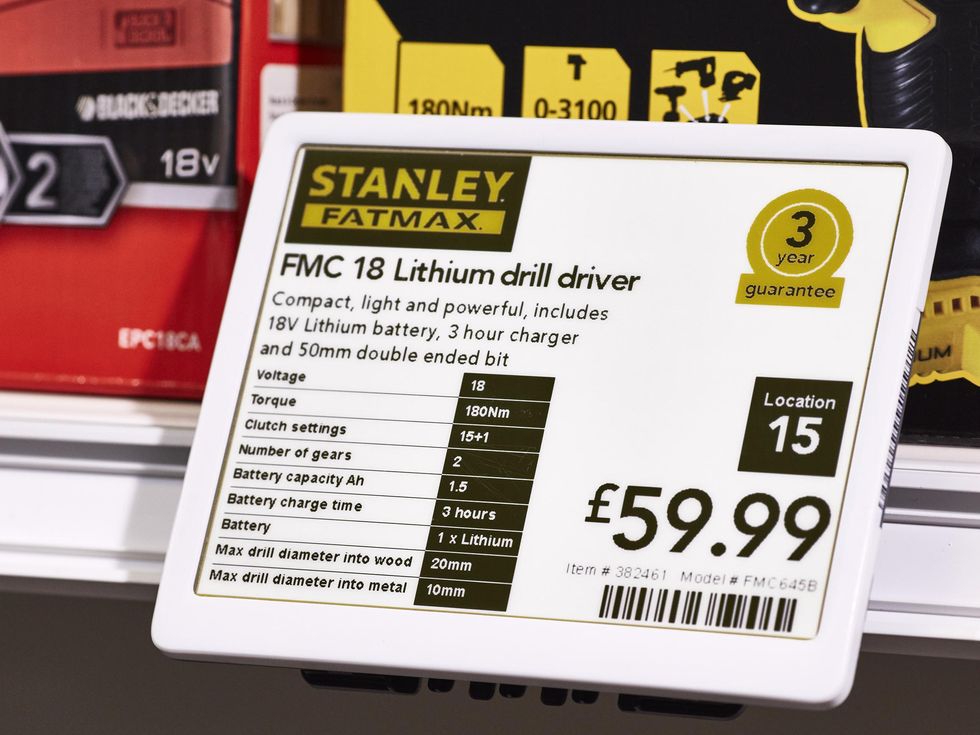

So, since the initial development of electronic ink, as the basic technology behind e-paper is known, and even more with the release of the Kindle, a big question hung over e-paper: When would we see this magical display in brilliant, blazing color?It’s not that people hadn’t been trying. Electronic-ink researchers had been pursuing color e-paper for years, as had other researchers around the world, in universities, corporate research labs, and startups. They came up with some early products that targeted shelf labels for brick-and-mortar retail stores and also for signage. But these added just one color to a black-and-white screen—red or yellow—and that wasn’t anybody’s idea of a full-color display. Indeed, more than a decade after that first Kindle, and more than two decades after its invention, full-color e-paper had still not reached the consumer market.

Why did it take so long for e-paper to make that Wizard-of-Oz transition from black and white to color? Over the years, researchers tried several approaches, some taking technologies from more traditional displays, others evolving from the original e-paper’s unique design. Qualcomm, for example, spent billions pursuing an approach inspired by butterfly wings. Overall, the path to successful color e-paper is a classic, if tortuous, tale of tech triumph. Read on to find out why this seemingly straightforward challenge was only realized just two years ago at E Ink, where we are chief technical officers.

Today, E Ink’s full-color ePaper is in consumer hands, in products including e-readers and smartphones and note-taking devices, and from roughly a dozen manufacturers. These include the Guoyue Smartbook V5 Color, the HiSense A5C Color Smartphone, the Onyx Boox Poke 2 Color, and the PocketBook Color. Only one other full-color electronic paper product has been announced—DES (Display Electronic Slurry) from China’s Dalian Good Display. At this writing, no devices using DES have shipped to consumers, though a handful of journalists have received samples and two Kickstarter campaigns feature products designed to use the display.

The challenge stemmed from the nature of the technology. Black-and-white electronic ink is a straightforward fusion of chemistry, physics, and electronics, and it does pretty much what traditional ink and paper does. E Ink’s version is made of microcapsules of negatively charged black particles and positively charged white particles—the same pigments used in the printing industry today—floating in clear liquid. Each microcapsule is about the width of a human hair.

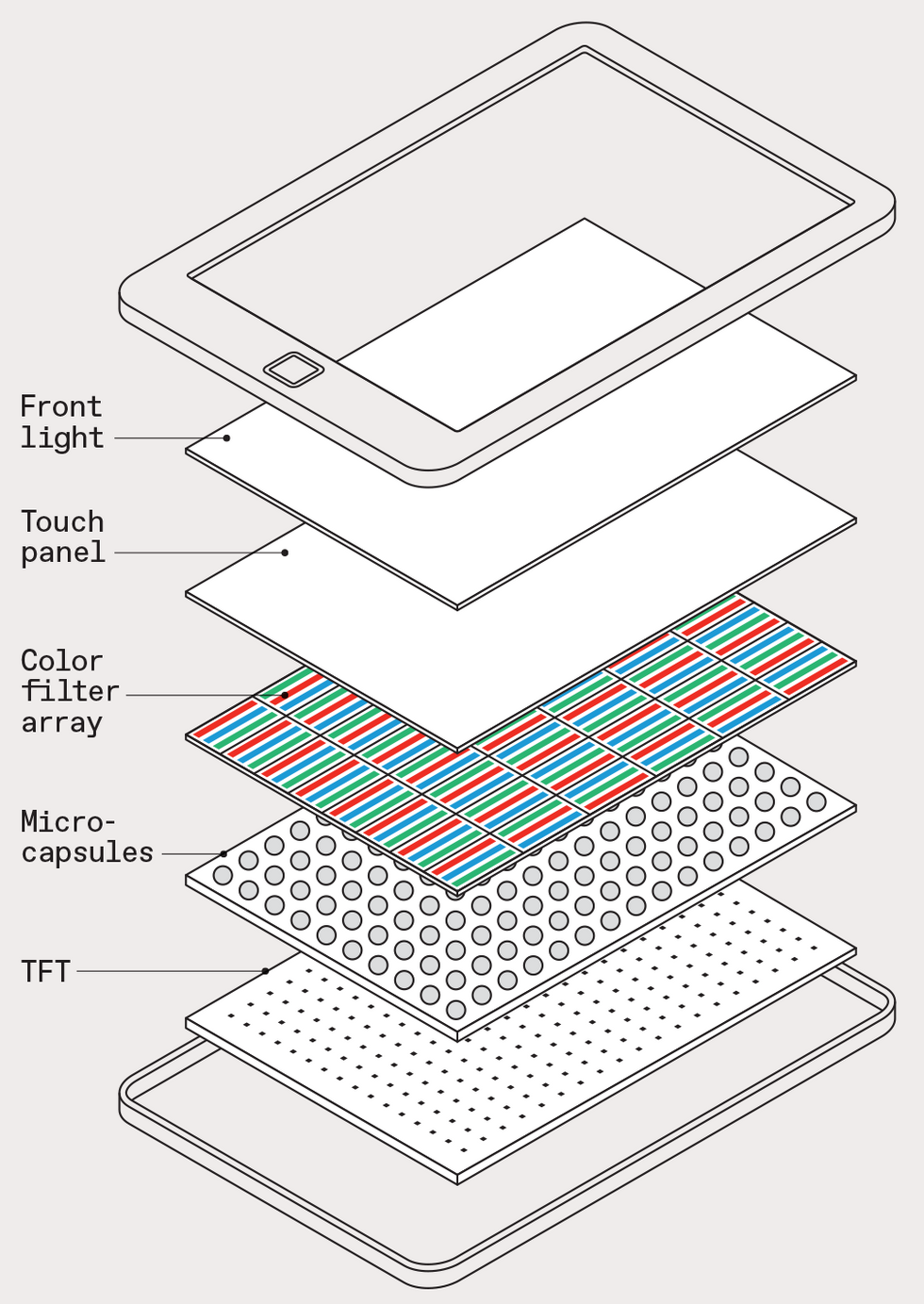

To manufacture our ePaper display, we start by making batches of this electronic ink, then use it to coat a plastic substrate some 25 to 100 micrometers thick, depending on which product it’s intended for. We then cut the rolls of coated film into the desired display size and add thin-film transistors to create electrodes above and below the ink layer, which is sandwiched between protective sheets, and, possibly, touch panels or front lights.

To produce an image, an ePaper device applies different voltages to the top and bottom electrodes to create an electric field. At the top, the voltage is close to zero, and at the bottom it alternates among –15, 0, or 15. Every time the image on the screen needs to change, a specific sequence of voltages applied to the bottom electrode moves the particles from their previous position to the position needed to show the correct color for the new image. This update time typically takes less than half a second.

Bringing white particles to the top of the display creates the appearance of “paper”; black ones create “ink.” But the particles don’t have to sit at the very top or very bottom; when we stop generating that electric field, the particles stop in their tracks. This means we can create a mixture of black-and-white particles near the top of the display—appearing as shades of grey.

The software that determines the timing and the voltages applied to each electrode is complex. The choices depend on what was previously displayed at that pixel. If a black pixel in one image will be black again in the next image, for example, no voltage needs to be applied at that spot. We also have to be careful with the transitions; we don’t want a previous image to linger, yet we don’t want an abrupt change to cause the screen to flash. These are but a few of the factors we took into consideration when designing the algorithms, called waveforms, that we use to set the sequence of voltages. Designing them is as much art as science.

To bring color into the equation greatly complicates the waveforms. Black and white is a simple dichotomy, given that an electric field can create either a positive or a negative charge. That approach can’t accommodate full-color digital paper. We needed something entirely new.

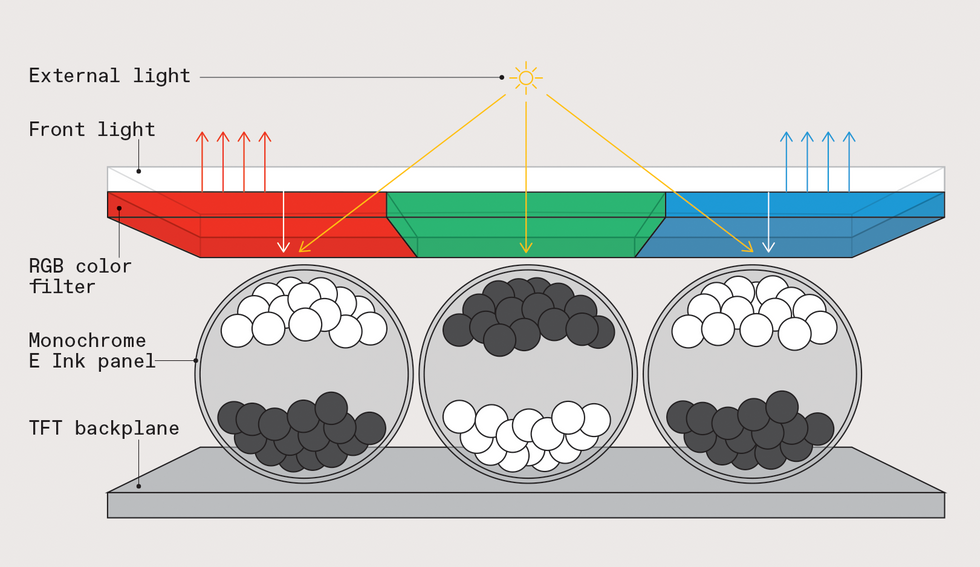

We started exploring options in the early 2000s. One of our first commercially launched color products, in 2010, used a color filter—an array of squares printed onto a layer of glass placed on top of the standard black-and-white ink layer. When we applied a charge to move the white particles to the surface at a selected spot, the light would bounce back to the viewer through the red, green, or blue filter above it. It was an obvious approach: All of the colors visible to humans can be created with combinations of red, green, and blue light, which is why most of today’s most common display technologies, like LCDs and OLEDs, use RGB emitters or color filters.

We called our product E Ink Triton. While an electronic textbook did launch with the technology, the main thing this effort taught us was what would not work for the consumer market. Its resolution was simply too low and the colors not bright enough for people who were used to the high resolution of tablet computers or print magazines.

The brightness problem stemmed from the fact that unlike LCDs and OLEDs, which, respectively, use a backlight or emit light directly, E Ink’s displays are fully reflective. That is, light from an outside source goes through the transparent cover, hits the ink layer, and bounces back to the viewer’s eyes. This arrangement is great for outdoor use, because reflective displays are enhanced rather than washed out by bright sunlight. And the displays are good for eye comfort, because they don’t shine light directly at a user. But with a reflective system, every layer between the ink and eye absorbs or scatters some of the light. Adding that color filter layer, it turned out, caused significant dimming.

In addition, using a color filter to split monochrome pixels into three colored pixels reduced the overall resolution. A display originally having a resolution of 300 pixels per inch, with an addition of a three-color filter, now has a resolution of 100 pixels per inch. This was not as much of an issue for a 32-inch display used as a sign—pixel sizes could be larger, and big letters don’t require high resolution. But it was a real problem for small fonts and line drawings on handheld devices.

While our researchers were coming up with this filtered display, others in our labs focused on a different approach, called multipigment, that didn’t rely on color filters. However, that approach requires far more complicated chemistry and mechanics.

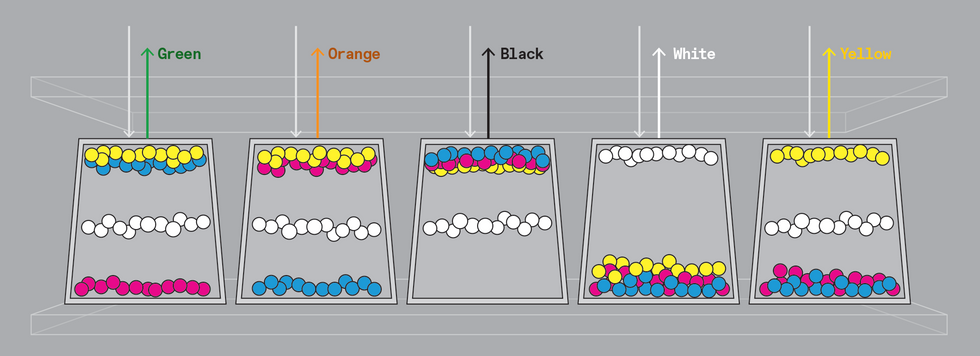

Multipigment e-paper also shares fundamentals with its monochrome predecessors. However, instead of only two types of particles, there are now three or four, depending on the colors chosen for a particular application.

We needed to get these particles to respond uniquely to electric fields, not simply be attracted or repelled. We did a few things to our ink particles to allow them to be better sorted. We made the particles different sizes—larger particles will generally move more slowly in liquid than smaller ones. We varied the charges of the particles, taking advantage of the fact that charge is more analog than digital. That is, it can be very positive, a little positive, very negative, or a little negative. And a lot of gradations in between.

Once we had our particles differentiated, we had to adapt our waveforms; instead of just sending one set of particles to the top as another goes to the bottom, we both push and pull them to create an image. For example, we can push particles of one color to the top, then pull them back a little so they mix with other particles to create a specific shade. Cyan and yellow together, for example, produce green, with white particles providing a reflective background. The closer a particle is to the surface, the greater the intensity of that color in the mix.

We also changed the shape of our container, from a sphere to a trapezoid, which gave us better control over the vertical position of the particles. We call these containers Microcups.

For the three-particle system, now on the market as E Ink Spectra and used primarily in electronic shelf labels (ESLs), we put black, white, and red or black, white, and yellow pigments into each Microcup. In 2021, we added a fourth particle to this system; our new generation uses black, white, red, and yellow particles. These are great for generating deeply saturated colors with high contrast, but these four colors cannot be combined to create full-color images. This technology was first launched in 2013 for retail ESLs. Companies have built E Ink screens into millions of these tags, shipping them throughout the world to retailers such as Best Buy, Macy’s, and Walmart. Similar electrophoretic shelf labels that use displays from China’s DKE Co. have since come on the market.

For our true, full-color system, which we call Advanced Color ePaper (ACeP), we also use four particles, but we have dropped the black and rely on white—our paper—along with cyan, magenta, and yellow, the colors used in inkjet printers. By stopping the particles at different levels, we can use these particles to create up to 50,000 colors. The resulting display renders colors like those in newspapers or even watercolor art.

E Ink launched ACeP as E Ink Gallery in 2016. Again, it wasn’t appropriate for consumer devices, because of slow refresh rates. Also, as it’s a reflective display without a backlight, the colors were too muted for consumers accustomed to bright smartphone and tablet displays. For now, it has been geared predominantly toward use in retail signs in Asia.

Realizing we still weren’t hitting the consumer-market sweet spot with our color displays, our R&D team went back to take another look at Triton, the system that used RGB color filters. What worked and what didn’t? Were there modifications we could make to finally produce a color e-reader that consumers would want?

We knew the filters were sapping brightness. We were pretty sure we could significantly reduce this loss by getting the filters closer to the electronic ink.

We also wanted to increase the resolution of the displays, which meant a much finer color-filter array. To get a resolution more in line with what consumers are accustomed to, we had to shoot for at least 200 pixels per square inch. That’s about twice the density we were able to achieve with our first round of Triton displays.

Compared with the complexity of formulating inks with a variety of charges, as we had done in developing ACeP, you might think this would have been easy. But it ended up requiring a new technology to print the color filters on the glass substrate.

We had created our earlier filters by printing semi-transparent red, green, and blue ink on glass. But this glass was an added layer. So we decided to print directly onto the plastic film that holds the top electrode, adding this step after our display modules were nearing the end of the assembly process. This arrangement would get the filters as close to the electronic ink as possible. It would also allow us to increase resolution, because aligning the filters with the display pixels could be done more precisely than was possible when using a separate surface.

We found the type of printer we needed at the German company Plastic Logic, a partner of E Ink since the early days of the company. But this printer was intended for use in an R&D lab, not for high-volume production. The processes it used had to be converted to operate in a different, production-ready machine.

We also needed to figure out new printing patterns for the color filter. These are the actual shapes and arrangements of the red, blue, and green filters. We had found through working on Triton that printing the filters as a simple square grid was not the best option, as the pattern could be visible during certain image transitions. And so the hunt for the perfect pattern was on. We went through many iterations, considering the angle at which light hit the display, as this angle could easily shift the color seen by the user. We evaluated a grid, straight printed lines, long lines, and a host of other designs, and settled on a pattern of short lines.

Because this is a reflective display, the more light hitting the display, the brighter it is. The research team decided to add a front light to the display, something that was not part of Triton, working hard to ensure that the light rays hit the ink layer at an angle that maximizes reflectivity. Using a front light increases energy consumption, of course, but it’s worth it in this case.

As a result, E Ink’s new color technology, E Ink Kaleido, has significantly more saturated colors and a better contrast ratio than E Ink Triton. And finally, a full-color electronic-ink display was ready for use in consumer products.

The first official batch of Kaleido displays rolled off the manufacturing line in late 2019. We began shipping to customers soon after, and you can now see the technology in products like the Hisense A5C, the iFlytek Book C1, and the PocketBook Color, all of which were launched in 2020. A second generation of Kaleido, called Kaleido Plus, began shipping in early 2021, with products released by Onyx and PocketBook and more launching soon. This update improved color saturation thanks to adjustments made in the printing pattern and the light guides for the front light.

We have a few things to work on. Light efficiency, the fraction of incoming light that makes its way back out to the user’s eyes, is good but it could be better. We are continuing to work on our film layers to further cut this loss.

By continuing to refine our printing pattern, we are also working to improve resolution by using denser circuitry in the electronics that sit below the ink layer and turn voltages on and off to move the charged particles.

We are also continuing to work on our filterless, multipigment electronic-ink technology. We expect to release a new generation for use in signage soon, and it will include brighter colors and faster page updates. Someday we might even be able to move this into consumer devices.

When E Ink’s researchers set out exploring color electronic ink in the early 2000s, they thought it would be a matter of a few years to fruition, given our expertise with the technology. After all, black-and-white e-paper took only 10 years from concept to commercialization. The road to full color turned out to be much longer. But, just like Dorothy in the Wizard of Oz, we finally made it over the rainbow.

This article appears in the February 2022 print issue as “E Ink’s Technicolor Moment.”

- Write Without Distraction With This DIY E-Ink Typewriter - IEEE ... ›

- CES 2011: Duel of the Color E-reader Displays - IEEE Spectrum ›

- BMW’s iVision Dee Brings Sci-Fi to the Driveway - IEEE Spectrum ›

- Amazon's Kindle Colorsoft Shows Yellowing Screen Issue - IEEE Spectrum ›

- E Ink Display Refresh Rate Reaches New Heights - IEEE Spectrum ›