Chemist Emmanuel Dellamarche held a thin slice of human thyroid tissue on a glass slide between his fingers. The tissue poses a mystery: does it contain a tumor or not? Dellamarche, who works at IBM Research in Zurich, Switzerland, turned the slide around in his hand as he explained that the normal method of diagnosing a tumor involves splashing a chemical reagent, some of which are expensive, onto the uneven surface of the tissue and watching for it to react with disease markers. A pathologist "looks at them under a microscope, and he's using his expertise, his judgment, and looks at what chemical he used, what type of color he can see and what part and he has to come up with a diagnosis," Dellamarche says, "he has a very, very hard job, OK?"

IBM is already good at precise application of materials to flat surfaces such as computer chips. Human tissue, sliced thin enough, turns out to receptive to the company's bag of tricks too. Dellamarche, turning to one of three machines on lab benches, explained that a few years ago his team began trying to deliver reagents with more precision. University Hospital Zurich will be testing the results over the next few months.

The idea was that instead of a sprawling blot occupying most of a tissue sample, a tiny tube something like an inkjet printer could deliver many droplets onto the tissue. Pathologists might put multiple reagents on a single fingernail-sized tissue sample, saving them the need for more samples and surgery. They might make better-informed diagnoses because the printer-like machine would allow them to control how much reagent to place on the tissue and where it goes. Pathologists could also compare the effects of well-measured doses on suspected cancerous parts. "We are interested in maybe thinking about technology to go from qualitative info to more quantitative information," Dellamarche says.

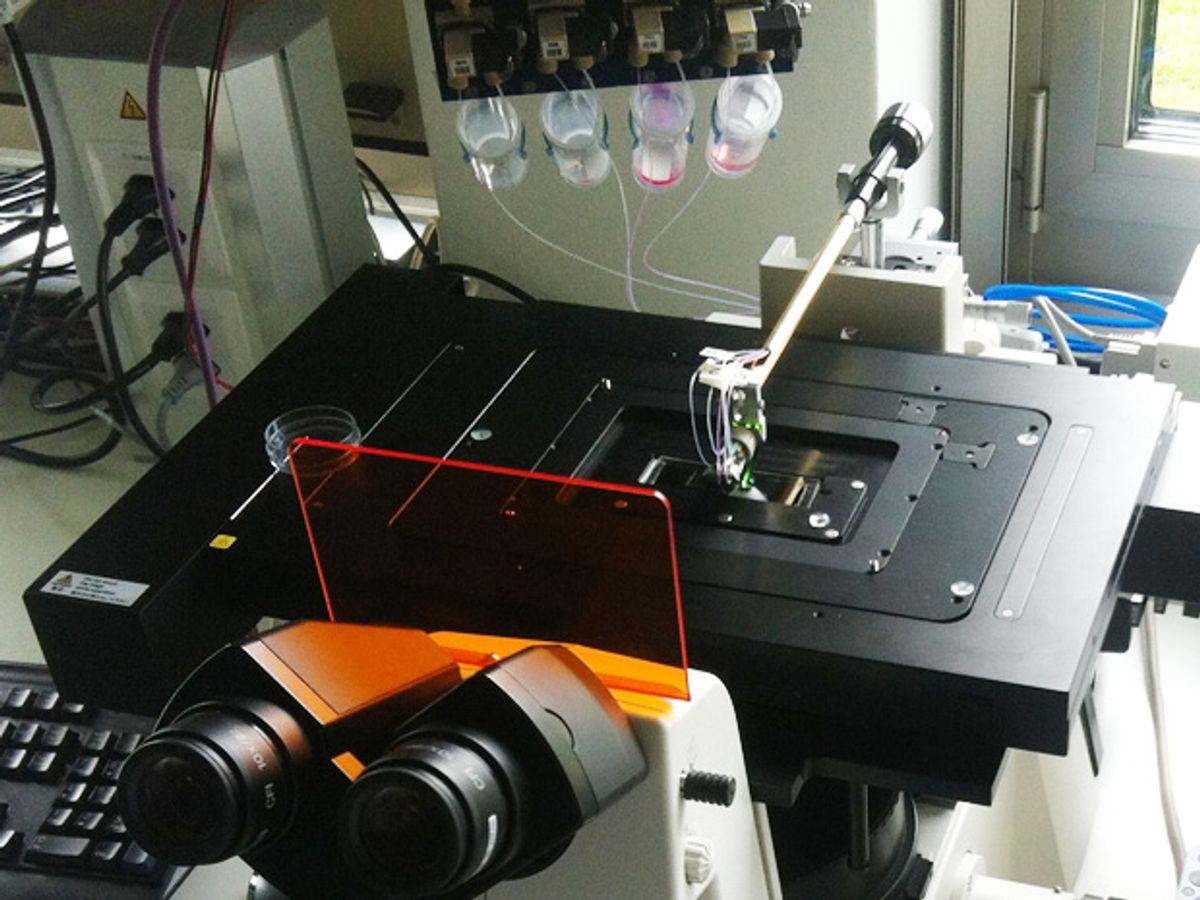

But that precise delivery of the reagents proved elusive. Some of it spilled outside the target area. In 2011 Dellamarche and colleagues announced a vertical microfluidic probe, that unlike previous microfluidic probes was not parallel to the target surface. It consisted of a glass and silicon wafer about one square centimeter with one channel about a micrometer across that shot liquid to the target and another channel that vacuumed up any excess. "The trick, or the invention actually, that we had was to put a second aperture that continuously re-aspirates what we inject," Dellamarche says. Today the team can create spots just 50 micrometers across, though he says the sweet spot for diagnoses may be more like a few hundred micrometers.

The microfluidic machine is part of a trend toward keeping samples put and moving the thing that analyzes them, according to a recent review in Lab on a Chip.

The technology is attractive both to pathologists, such as those at University Hospital Zurich, and to basic researchers, with whom Dellamarche and mechanical engineer Govind Kaigala can share a larger, more customizable version in their lab.

Photo: Lucas Laursen

Lucas Laursen is the technology policy editor at IEEE Spectrum. He covers how emerging technologies are changing the balance of power between companies, governments, and individuals. The rest of the time, he worries about his own balance on a bicycle, skis or the side of a mountain.