Homemade

By giving everyone the means of production, personal fabrication systems could usher in a new age of customization

“Fabbers—machines that rapidly create useful items on demand from computer-generated design specifications—have been fantasy fodder for decades. And for good reason: a machine that could make a huge variety of reasonably complicated objects, and yet was attainable by ordinary people, would transform human society to a degree that few creations ever have.

To understand why, consider the vision offered by Neil A. Gershenfeld, professor at the Massachusetts Institute of Technology, in Cambridge, in his recent book, Fab: The Coming Revolution on Your Desktop—From Personal Computers to Personal Fabrication (Basic Books, 2005). Gershenfeld describes his ongoing project to equip ordinary folks with machines that were once used exclusively by manufacturers to prototype new designs. With such machines, people can, in effect, “download” such complex objects as bicycles, chemical sensors, radios—and eventually robots, and maybe even prosthetic limbs—much as they now download music and video files.

Fabbers of seemingly unlimited capability also buttress lots of recent science-fiction plots. The “matter compiler” of Neal Stephenson’s book Diamond Age (Bantam Books, 1995) is a memorable example. And in Alistair Reynolds’s trilogy of space operas, interstellar spaceships rely on fabbers to produce everything from weapons to furniture.

While that kind of capability may be decades if not centuries away, researchers at several universities, including Stanford, Carnegie Mellon, MIT, and the University of Bath, are already investigating technologies and materials that could lead to general-use, compact fabbers. At Cornell University, in Ithaca, N.Y., my group in the Cornell Computational Synthesis Laboratory has taken the first steps toward what we hope will be a significant milestone: the creation of a fabricating system that can produce small, simple robots incorporating a battery, actuators, and sensors. Our goal is to one day see little automatons wriggle, completely finished, out of our apparatus, their electronic and mechanical subsystems having been created in one seamless process—batteries included. In the meantime, we recently succeeded in creating a small fabber that we used to make a coin-shaped battery and an actuator suitable for our envisioned robot.

Compact and yet capable fabbers point the way toward a future where the term “online shopping” takes on a whole new meaning. Imagine purchasing a piece of software that encodes detailed specifications of something and then seeing that object emerge from a box on your desk no bigger than a microwave oven. Like your desktop printer today, this desktop fabber would use some sort of cartridges. And just as desktop-printer cartridges contain the inks that can produce a limitless variety of images, the fabber cartridges would contain the necessary raw materials to create a profusion of desired items.

Not every consumer product is suitable for fabbing, of course, but anything whose materials cost is low compared with its intellectual investment is a contender. A few examples are electric toothbrushes, cellphones, eyewear, toys, costume jewelry, and other decorative items [see sidebar, "Download Museum Pieces Today"].

Although many technical hurdles must be cleared before home fabbing can become a reality, it’s already possible to see its huge implications for engineers, designers, and distributors. Manufacturing, at least for things that could be fabbed, would be divorced from rigid corporate control, spawning new classes of independent designers. Much of the stock and delivery costs associated with conventional manufacturing would be eliminated. And with appropriate software, a product could be customized, enabling a system of bespoke production almost inconceivable today.

Although it sounds farfetched, home fabbing has a precursor in the array of rapid-prototyping systems now used routinely in various industries. These include some systems for electronics and others for mechanical prototypes—but none, crucially, that can rapidly create a prototype of an object incorporating both electronic components (such as resistors) with mechanical ones (such as ball joints). The electronics-oriented systems fall under the category of direct-write electronics; the mechanical ones are called solid-freeform fabricators and can make objects of any shape. During the past 30 years solid-freeform prototyping has matured into a multibillion-dollar industry.

Rapid-prototyping systems, both electric and mechanical, work by incrementally and selectively depositing material from a source onto a substrate. The machines read data describing slices of a computer model and, using one of several methods, lay down successive thin layers of liquid or powdered polymers, ceramics, or metals.

The solid-freeform systems are commonplace tools for industrial designers. They are used mostly by automakers to create prototypes of car parts, from engine blocks to side-view mirrors; by appliance manufacturers to model products such as air conditioners and microwave ovens; and by consumer electronics companies to model Bluetooth headsets, cellphones, and other products. The industrial rapid-prototyping systems use inks, pastes, and suspensions that are combinations of filaments, powders, flakes, precursors, cross-linkers, binders, solvents, dispersants, and surfactants, whose properties—including viscosity, density, melting point, and surface tension—are tailored to particular applications.

Currently, rapid prototypers can fashion plastics, ceramics, and certain metals into almost any kind of mechanical structure, including sliding and rotary kinematic joints, links, springs, gears, ratchets, nuts, and bolts, with quality good enough for functional testing. Many solid prototypes incorporate a tough, rigid plastic, called acrylonitrile-butadiene-styrene (ABS). Electronics maker Logitech Inc., in Fremont, Calif., used a solid-freeform machine from Stratasys Inc., in Eden Prairie, Minn., to make an ABS prototype of its Bluetooth headset and then attached weights to the boom microphone to test the design for strength. Another Stratasys customer, Diebold Inc., in North Canton, Ohio, builds automated teller machine prototypes made of ABS or polycarbonate and tests their endurance in rain, sleet, snow, and extreme temperatures. Grotell Design Inc., in New York City, makes prototypes of all its watch components, from bracelets to bezels, using thermoplastics, natural and synthetic waxes, and even fatty esters in desktop solid-freeform fabricators made by Solidscape Inc., in Merrimack, N.H.

For electrical engineers, direct-write methods for creating electronic prototypes have progressed from their origins as simple plotters for electronic circuits to an emerging family of commercial machines. The new machines, which can deposit a variety of materials over different surfaces according to a software design, are used mostly for printed-circuit board models. With inkjet, plasma, thermal spray, pen, and laser-based methods, they lay down lines ranging in width from nanometers to centimeters. The prototypes are made from metals, ceramics, ferrites, semiconductors, and polymers, as well as various composite materials such as polymer ceramics for resistors and similar components. The techniques work at low temperatures and can write lines at speeds approaching one meter per second [see sidebar, "Technology For Future Fabbers"].

Today’s most advanced direct-write techniques work not only on flat boards but also on nonplanar substrates, flexible plastic substrates, and even textiles to make flexible and compact circuits that conform to the tight space requirements of certain consumer products. Because direct write lends itself not only to prototyping but also to small-scale production of specialty parts and devices, the U.S. Defense Advanced Research Projects Agency has poured millions of dollars into the technologies’ development. DARPA is funding a project by Potomac Photonics Inc., in Lanham, Md., to develop and commercialize laser-based direct-write tools that can deposit metal, dielectric, and ferrite materials onto a variety of substrates by melting a stream of powdered material such as titanium. It will make custom circuit boards, complete with conductive traces, resistors, capacitors, and inductors. Another DARPA-funded company, MesoScribe Technologies Inc., in Stony Brook, N.Y., has developed a thermal-spray technique that accelerates particles to directly write a thermocouple on a curved, ceramic-coated gas turbine blade to monitor the heat of fuel combustion.

Like countless other technologies, rapid-prototyping systems are getting faster, cheaper, and better. But today’s machines have several obstacles to overcome before they can become fairly general-use home fabbers. For one thing, rapid prototyping is something of a misnomer: with typical printing rates of about 1 cubic inch per hour, it can take as long as a day to produce even a simple plastic shape representing a toaster in one of today’s solid-freeform fabrication systems. And the systems are difficult to use, requiring a fair amount of specialized knowledge. Plus, they cost anywhere from US $15 000 to $750 000.

Furthermore, a single freeform machine cannot make parts composed of different materials. And even if a machine existed that could handle multiple materials, the commercial software needed to tell the tools when to apply, say, plastic on one layer and metal on the next doesn’t exist yet. Finally, the range of materials rapid-prototyping systems can work with, while expanding, still does not include materials that produce motion in response to electrical impulses, and chemical systems and separators that can be used to make batteries. For our robots to be able to walk right out of the fabber, we need to fabricate and embed complex actuators seamlessly, along with the power sources to drive them.

The key is in the materials—corresponding to the inks in a desktop printer—that home fabbers will use, which we are starting to engineer in our lab. When we talk about printing objects from a desktop fabber, we mean that inkjet printer nozzles that spray micrometer-size droplets of materials for thin films will work side by side with high-tech extruders—called fused-deposition modelers—that dispense thicker materials. The machine will build objects according to software instructions by sequentially depositing onto a substrate a variety of liquids chemically tailored to provide certain mechanical or electrical functions, or both, once they dry.

For several years, our group and others, such as the robotics group at Rutgers University, in New Brunswick, N.J., have used fused-deposition modeling and the oldest form of solid-freeform fabrication, called stereolithography, to make parts of small robots that include intact joints with balls printed inside their sockets. The Rutgers group’s simple robots can crawl or roll around, but only after researchers manually embed the sensors and actuators. Professors Friederich B. Prinz and Mark R. Cutkosky of Stanford University, in California, and Lee Weiss, principal research scientist at Carnegie Mellon University’s Robotics Institute, in Pittsburgh, have taken robo-fabbing to the next level by having the machine automatically insert electronic components on the fly as it makes the robot.

We want to go even further and create a robot that has the sensors, actuators, and power supply integrally fabricated as part of a single process. Like living creatures, with their biological muscles intertwined with nerves, our robots need actuators with embedded sensors and logic that are connected to batteries. The ability to print actuators and batteries directly from raw materials would not only save assembly time and effort, it also would allow us to explore new structures for the devices, as well as better ways to integrate them with the system.

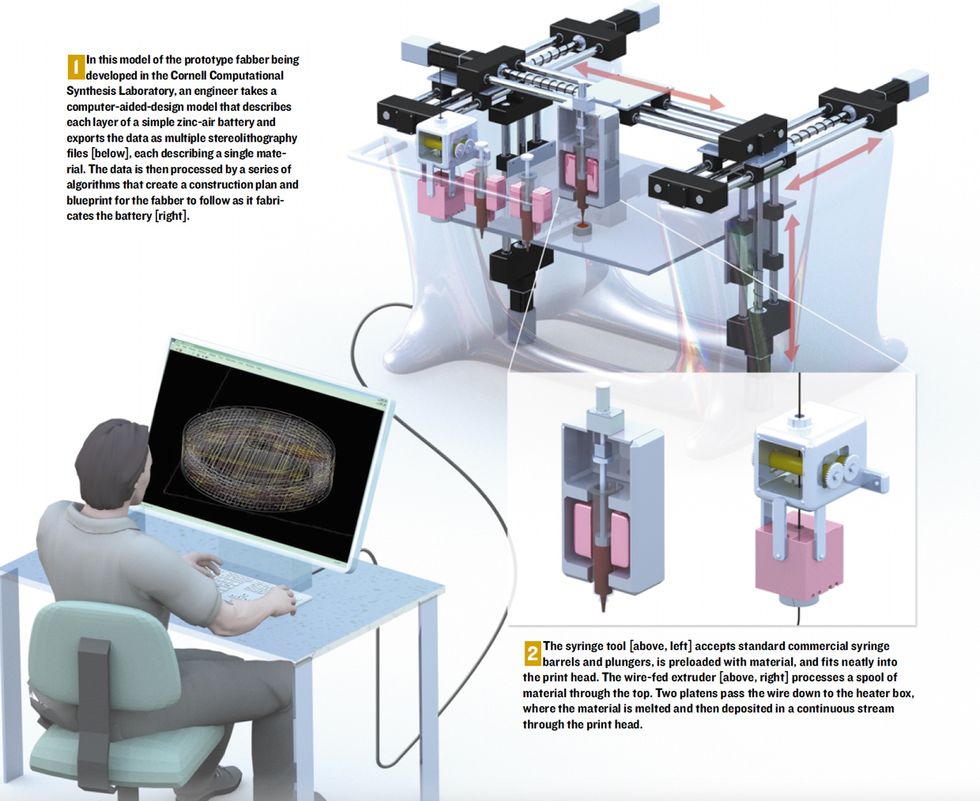

We’ve built a fabber in our lab that creates functional objects with multiple materials without human intervention. It is, in effect, a robot that makes robots. This fabbing robot does the main work, positioning the item and changing the deposition tools and materials automatically according to the computer-generated design. In form and function it resembles the gantry cranes used to load and unload freighters. It can move the object up and down, backward and forward, and from side to side. Most current rapid-prototyping systems, both mechanical and electronic, use such a platform but fall short of our specific needs. We designed our gantry robot to accelerate a 5-kilogram payload with 25-micrometer precision very fast—20 meters per second squared—so the print head can follow paths having tight turning radii without slowing down, to maintain a constant deposition rate. The same gantry robot also changes the tools. The head moves to a bank where tools, which have material cartridges inside them, can be loaded and unloaded as necessary. One tool is a custom-built wire-fed extruder, the other a custom-built syringe. The cartridge-bearing tools are swapped according to the specifications of the next layer to be laid down [see diagram, "Fab In the Lab"].

Our extruder handles metals and plastics with a wide variety of diameters, hardnesses, and melting points. It directly deposits material at adjustable rates in a continuous stream by unwinding a filament 0.13 to 0.18 centimeters in diameter from a coil and delivering it to a computer-controlled, heated nozzle. The nozzle melts the plastic or metal filament and deposits a 250-µm-diameter stream of the molten material, layer by layer, in the geometric patterns specified by the computer. With this tool, we typically use polypropylene and ABS thermoplastics, and low-melting-point alloys of such metals as lead and tin.

To deposit liquid and chemical pastes—for instance, material for conductive wires, polymer films for actuators, and suspended zinc powder for batteries—we use a syringe tool that accepts standard commercial syringe barrels and plungers. These syringes are carried in “smart” packages that can communicate with the printer head to indicate what materials they hold and when they are in place. Such a smart package might also keep the material at a specific temperature or vibrate it to keep suspended particles from settling.

Using a computer-aided-design (CAD) model as input, our software generates the paths for the tools to follow and a fabrication sequence of materials and tools. We define the objects to be printed with stereolithography files, which describe the object’s geometry as a list of millions of triangles that tessellate its surface. In our system, each file describes a single material. Each material is associated with a deposition tool and properties governing its thickness, deposition path width, and deposition rates. Algorithms that take into account the tool’s and material’s parameters generate paths for the print head to follow and the sequence in which layers are laid down. The control computer translates the paths and fabrication sequence into a series of motion commands, deposition rates, and tool-exchange commands for the gantry robot to follow.

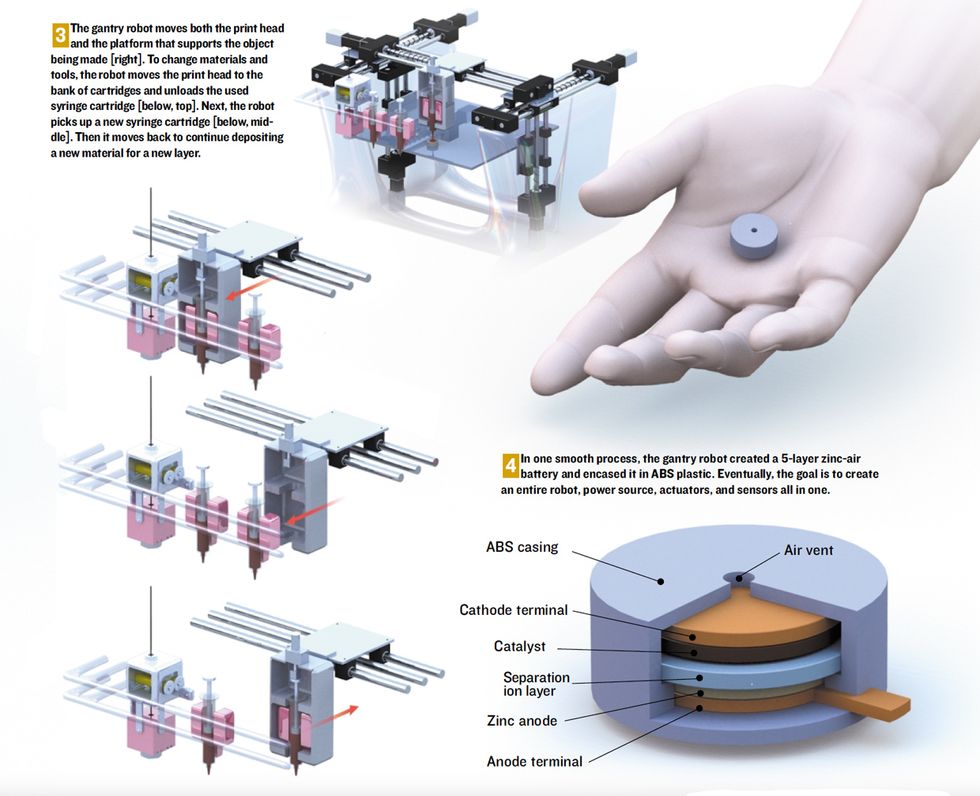

To power the products our fabber makes, we developed printable 3-D zinc-air batteries. Our freeform process lets us design a cell to be embedded anywhere in an object of any shape, freeing our robot designs from the physical constraints imposed by the characteristics of conventional batteries.

We settled on a battery that uses zinc and air as its reactants because of simplicity and relatively high energy density. In developing liquid materials for the battery, we came up with zinc powder suspensions that would not clog the syringe nozzle. We also had to develop a material that would act as a separation layer between the zinc anode and the air/catalyst cathode. This separator needs to be porous to allow the transfer of ions in the electrolyte, while preventing shorting between the anode and the cathode. In commercial batteries, that separator is typically made of paper. In our battery, the separator is made of ceramic slurry or the synthetic resin, polyvinyl alcohol.

After a few trial runs, our fabber produced a printed zinc-air cell about the size of a coin, composed of five layers of different materials in a plastic case. It delivered 10 milliwatts for almost 50 hours to a small dc motor. More important, we proved that it is possible to make functional items of several different materials in a single process.

Power source in hand, we turned our attention to the mechanism for moving our freeform robots, and began formulating a novel, and cheaply manufacturable, liquid starter material for actuators.

We based our actuator on ionomeric polymer-metal composites (IPMCs). The composites are typically grown using slow electrochemical processes that are not compatible with freeform fabrication. But after almost two years of research, my Cornell colleague Evan Malone and I succeeded in engineering a set of materials and deposition processes that produce printable electroactive actuators.

In most robotics labs, IPMC actuators are constructed from the same kind of polymer composite membrane used as the catalyst layer in proton-exchange-membrane fuel cells. Nafion is the trade name for the version of this membrane made by DuPont Inc. A voltage applied across the electrodes embedded in the membrane’s surface causes the material to bend, probably as a result of migration of positively charged ions toward the cathode, along with some other chemical effects.

We make IPMC actuators by taking a solid membrane and replacing the positive hydrogen ions with larger positive lithium ions. We then attach metallic electrodes to the surfaces of the membrane by soaking it in a metal salt solution and letting it dry. A rapid-prototyping machine can’t handle either of those steps. So instead of processing prefabricated membranes, we prepared our actuator material by mixing liquid Nafion with a solution of lithium hydroxide. The large lithium ions replaced the small hydrogen ions in the Nafion molecules. The free hydrogen ions bound to the remaining hydroxide molecules to form water. We let the water evaporate and were left with actuatable lithium Nafion.

We thought that the raw actuator material could be used to cast thin films. However, the films cracked upon drying, and the pieces were too fragile to handle. To solve the cracking problem, we added a solvent, dimethylformamide, to the raw actuator material and heated the cast film for 15 minutes at 135 degrees centigrade. We wound up with transparent, durable films that could be actuated, but to make them compatible with rapid-prototyping machines, we needed to eliminate the heating stage. To do so, we dissolved a small quantity of a special kind of rubber in the dimethylformamide to help reinforce the raw actuator material. The end result was a high-quality cast film that required a minimum of processing. We deposited the reengineered Nafion with silver powder, carbon black, and a surfactant to act as electrodes and successfully actuated it. Now we are working with low-melting-point metal alloys, such as lead-tin solder, and conductive rubber to produce wiring to serve as our robotic nervous system, and with carbon-based electronic materials to print transistors for robotic brains.

Although our group and others have made a great deal of progress during the last five years, many technological challenges stand between the laboratory systems of today and the universal fabber of tomorrow. For example, direct-write technologies are usually designed for smooth, planar surfaces, but for integration with solid-freeform fabricators, thin-film deposition must be adapted to rough 3-D surfaces. Researchers must investigate numerous material-compatibility issues and eventually settle on a compact set of multifunctional materials. Furthermore, we need to develop standard file formats to specify multimaterial objects so people can freely exchange design blueprints, just as the Adobe PostScript standard was developed to communicate with laser printers.

The fabber platforms need some work, too. The gantry robot worked well for our zinc-air batteries, but imagine if we had a robot that allowed both the object and the writing head to move in six degrees of freedom on articulated arms. This architecture is much more complex mechanically and difficult to control but may offer several advantages. Primarily, the object can be grown from the inside out like an onion. The added flexibility allows more control over spatial orientations—which may be important in achieving some mechanical and electrical properties, such as orienting fibers along stress concentration paths and depositing conductive wires in continuous strokes. It also lets the machine reorient the part to print overhanging features more effectively. This architecture may also allow the machines to perform some assembly tasks as well, such as building objects larger than the printer itself, which would permit self-repair and self-extension.

Whereas much of the current hype surrounding fabbers centers on the practically endless possibilities for home use, the first commercial success for multimaterial rapid prototyping might be synthetic implants for medical applications. Nowhere is there a greater need for unique, custom objects, which would be tailored to patient dimensions. But why stop at synthetic implants? Together with Cornell colleagues Lawrence Bonassar and Daniel L. Cohen, my group is developing the materials to print 3-D replacement bone and cartilage implants constructed from the patient’s original cells. Using a CT scan or MRI, the machine would form the implants into the desired shape with the correct distribution of the patient’s cells. Such implants would be less likely to be rejected or to wear out.

And just imagine the possibilities of fabbers and computers getting together to design robots and other things on their own. That is what drew us into the quest for printable robotics in the first place. In August 2000, together with Jordan B. Pollack, a professor at Brandeis University, in Waltham, Mass., we developed a program that—for the first time—designed and fabricated mobile robots with nearly no human intervention [see photo, ].The design automation program emulated principles of natural evolution, with hundreds of robots over hundreds of generations in a simulated world. Successful robots were copied from the virtual world into the physical world using a 3-D printer. The process resulted in odd-looking white thermoplastic creatures that could crawl across the table.

In that experiment, we manually inserted the motors, batteries, controller, and wiring according to the evolved design. But what would have happened if we had allowed the process the freedom to design and make its own wiring, actuation, and energy? We believe it would have come up with an even better design. Multiple experiments in other domains have shown us that removing constraints from our engineering preconceptions allows new, often better designs to emerge. Removing the constraints on the way we manufacture and consume everything from watches, toys, and cellphones to MP3 players, mops, and meat cleavers might let us create a whole new kind of economy for a custom-built world.

About the Author

Hod Lipson has been an assistant professor in the department of mechanical and aerospace engineering at Cornell University, in Ithaca, N.Y., since 2001. Previously, he was a postdoctoral researcher at Brandeis University and the Massachusetts Institute of Technology, working on evolutionary robotics and design automation. This article is based on his work with Evan Malone, Daniel L. Cohen, Lawrence Bonassar, and Francis C. Moon.

To Probe Further

To learn more about how personal fabrication is making a difference in people’s lives today, read Fab: The Coming Revolution on Your Desktop—From Personal Computers to Personal Fabrication, by Neil A. Gershenfeld (Basic Books, 2005)

Download your own kinematic machine at https://kmoddl.library.cornell.edu/.