By employing the principles used to make holograms, scientists have developed microscopic high-energy, high-power 3-D lithium-ion batteries that they can fabricate directly on microchips.

Existing thin-film microbatteries can deliver high levels of power, but when sized to store a reasonable amounts of energy they take up too much of a chip’s area. To reduce the battery’s footprint and improve microbattery performance inventors have sought to expand into the third dimension with complex 3-D structures that increase the amount of surface area available for electricity-generating chemical reactions. However, it has proven challenging.

Now scientists at the University of Illinois at Urbana-Champaign are using the same principles employed to make holograms to help create advanced 3-D microbatteries. Holography uses patterns of laser beams that interfere with each other in precise ways to encode holograms. Holographic lithography systems fire laser beams at a photosensitive material, and the way these beams interfere with each other can make complex 3-D structures harden into existence in that material in just seconds. The researchers noted that 3-D holographic lithography is highly scalable and compatible with existing microfabrication techniques.

The researchers developed a 10-micrometer-thick 4-square-millimeter 3-D microbattery that could reach a peak current of 500 microamperes, store 65 microwatt-hours of energy per square centimeter, and deliver 36 milliwatts of power per square centimeter.

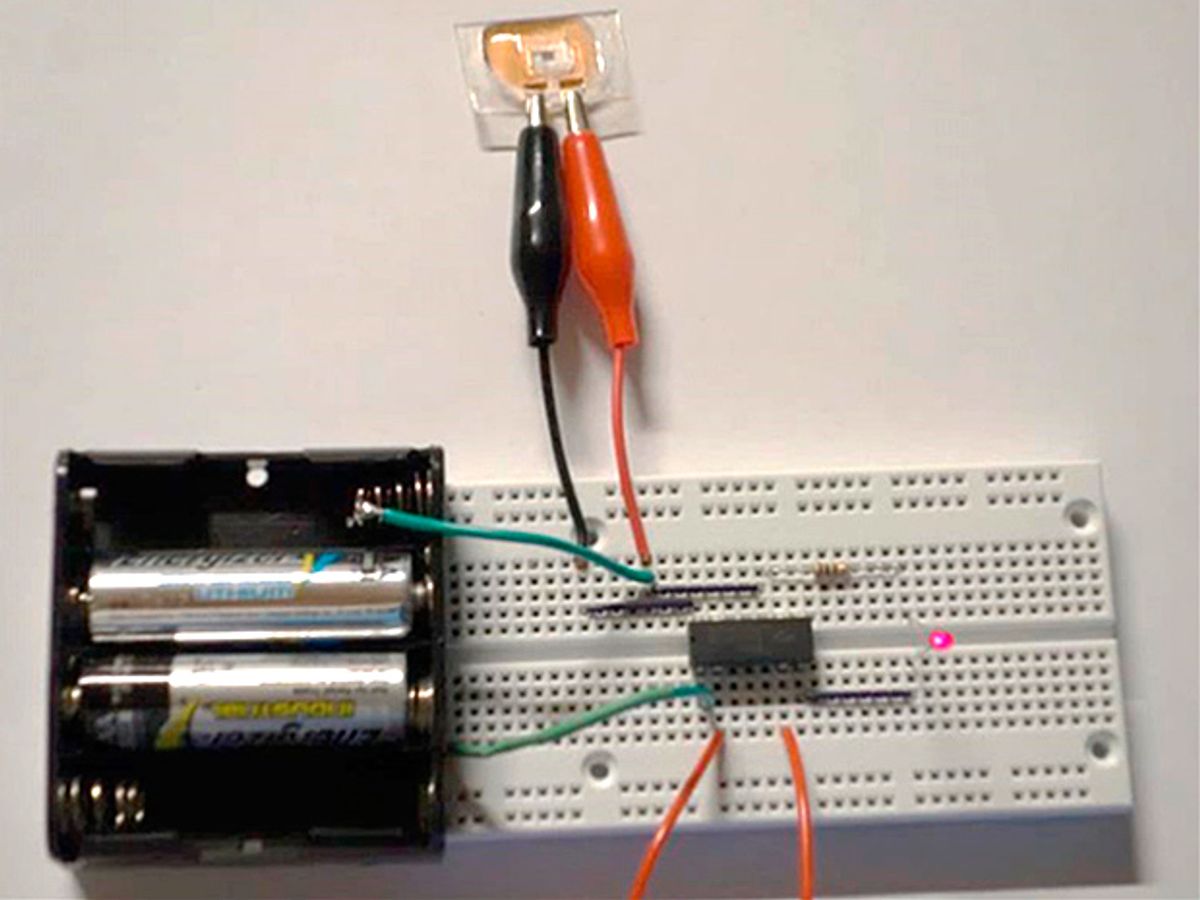

They showed their device could light a conventional red LED at least 200 times for 10 seconds each time, and the microbattery only lost 12 percent of its capacity after 200 cycles of discharging and recharging. The researchers noted that practical microbattery applications probably need to live through at least a few hundred such cycles, and their device performed considerably better than previous 3-D micro-batteries that at best faded after a few dozen cycles.

The researches suggest that miniaturized on-chip batteries could help power a bevy of applications such as microscopic sensors and portable and implantable medical devices.

They detailed their findings online 11 May in the journal Proceedings of the National Academy of Sciences.

Charles Q. Choi is a science reporter who contributes regularly to IEEE Spectrum. He has written for Scientific American, The New York Times, Wired, and Science, among others.