Graphene is a pure conductor, just like a metal, which has led researchers to examine applications like antennas to see if graphene could serve as a replacement.

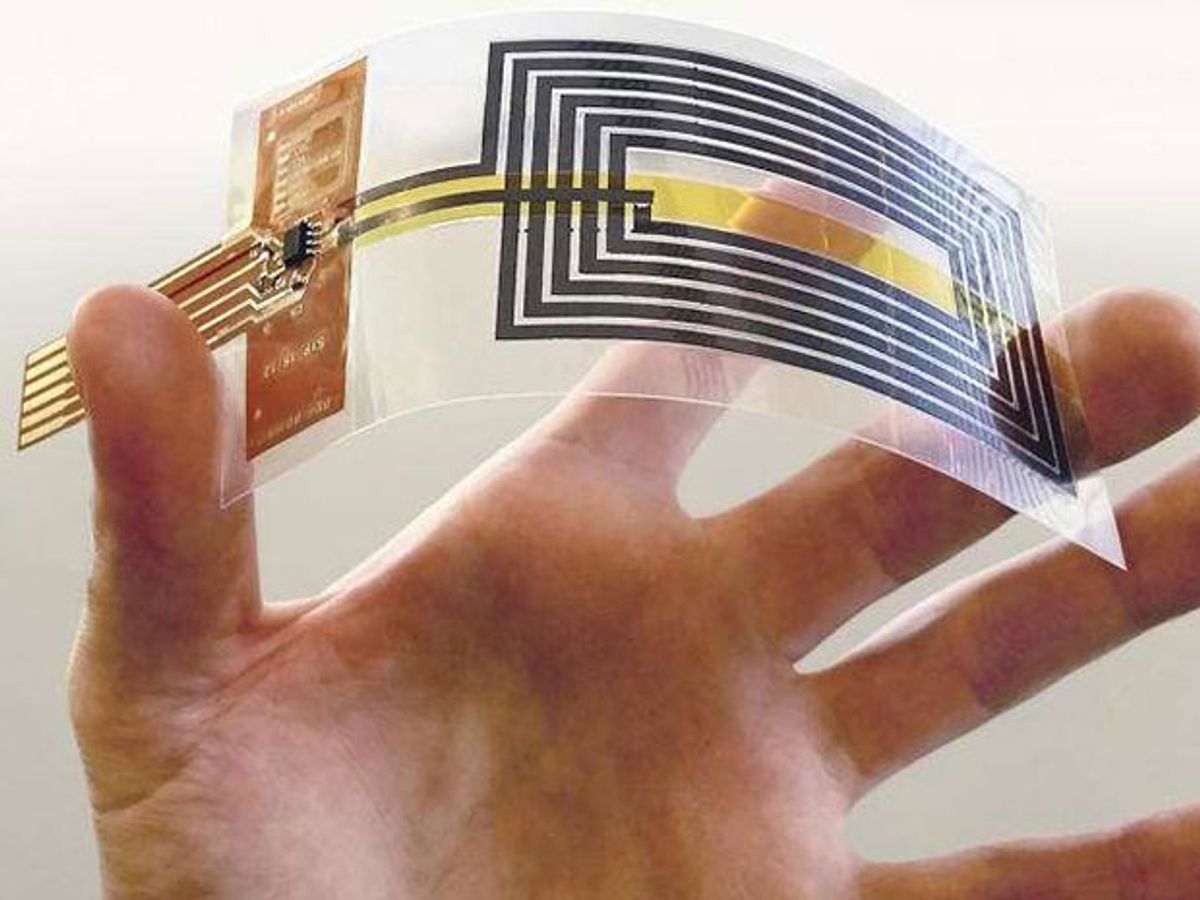

Along this line of inquiry, researchers at the National Research Council Institute for Organic Synthesis and Photoreactivity (CNR-ISOF) in Italy, which is part of Europe’s Graphene Flagship, have developed a graphene-based near-field communication (NFC) antenna. Unlike today’s NFC antennas their devices are flexibile and have greater durability.

These NFC antennas are a ubiquitous method for two electronic devices to transfer data to each other. Anytime you need a way to communicate a small amount of data over a relatively short distance wirelessly, a NFC antenna is probably involved. They are used in security cards, tracking of inventory and payment systems.

“A key target for modern technology is to replace metals with lighter, cheaper, less energy-consuming and better recyclable materials,” said Vincenzo Palermo, a scientist at CNR who led the research, in a press release. “Due to its unique combination of superior properties, graphene can be used to produce fully flexible NFC antennas.”

The Graphene Flagship and its research partner CNR-ISOF are extremely keen on this technology based on the press release they put out this week. But it’s not the first time they’ve crowed about it. They presented the technology at mobile conferences taking place over the last year in Shanghai and Barcelona. In fact, in the video below you can see Palermo demonstrating the graphene-based NFC antenna at the Barcelona Mobile World Congress last February.

The interest in this technology is not limited to just the enthusiasm of CNR-ISOF and the Graphene Flaghship. Electronics giants like STMicroelectronics and Nokia have been helping with the development of the technology. It would appear that the graphene has become of real strategic interest for Nokia, which has looked to use the material to create flexible displays and waterproof phones.

Whether all this enthusiasm and corporate interest is leading to any commercial products remains unclear, and this week’s latest press release clouds the issue even more. Why aren’t they announcing a commercial product instead of the research, which seems to be fairly far along at this point?

In fact, this week’s press release serves as an invitation to more industrial partners to help in developing the technology. “We are exhibiting at the Composite Europe 2016 to find new industrial collaboration partners to develop the graphene based NFC antennas into large-scale production,” added Palermo in press release.

Without having any answers to the question, it is easy to speculate that the cost of graphene for making NFC antennas could be prohibitively higher than the metals typically used. Whether large-scale production can lower those costs might be the big sticking point for the technology to move forward.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.