While the wonder material graphene continues to come under pressure from other two-dimensional materials in electronics applications, it has continued to build up applications far afield from electronics.

One of the applications that has opened up over the last year is rustproofing. In May of this year, researchers from the University of Buffalo demonstrated that they could use graphene in rustproofing steel.

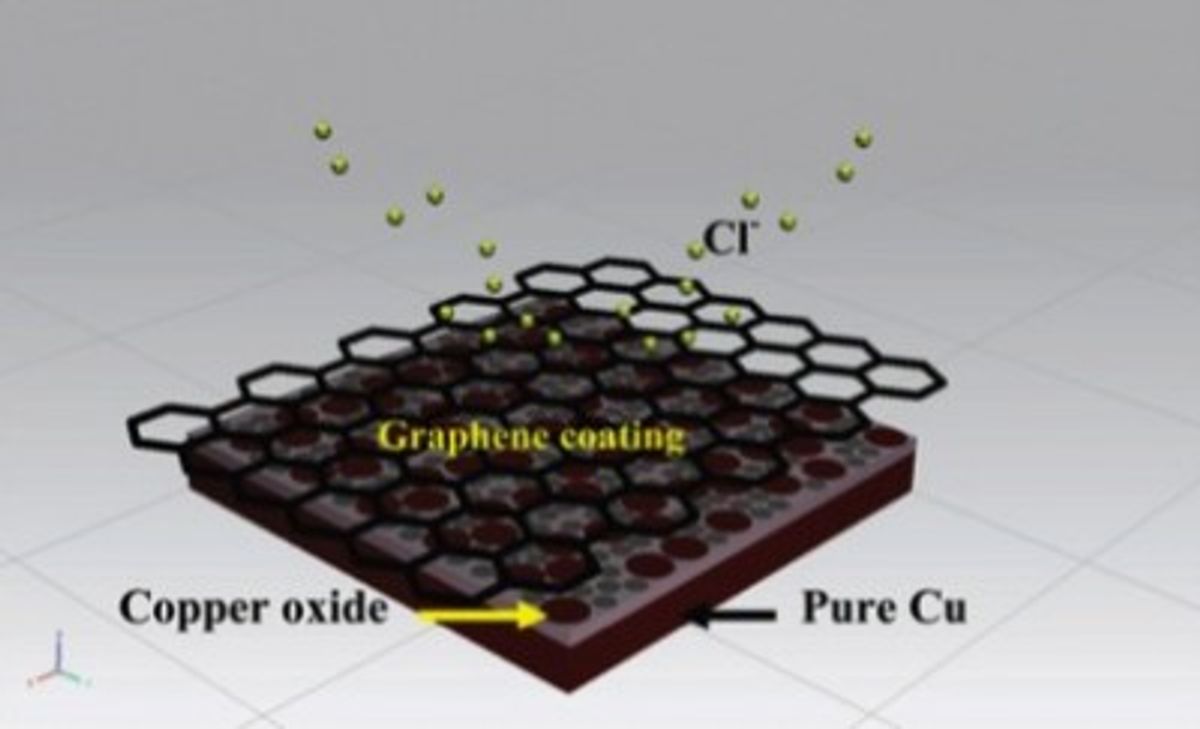

The research, which was published in the journal Carbon (“Protecting copper from electrochemical degradation by graphene coating”), claims that the graphene-based coating renders copper nearly 100 times more resistant to corrosion than if left unprotected.

“We have obtained one of the best improvements that has been reported so far,” says study co-author Dr Mainak Majumder in the university press release. “At this point we are almost 100 times better than untreated copper. Other people are maybe five or six times better, so it’s a pretty big jump.”

To achieve the atomic-scale rustproof coating, the researchers simply heated the graphehe to temperatures between 800 and 900 degrees celcisus and then applied the graphene to the copper through chemical vapor deposition. Seeing whether they can apply the graphene coating at a lower temperature will be a focus for future research.

The University of Buffalo researchers explained that their research into rustproofing steel was in part motivated by a desire to find a more environmentally friendly method than the chrome electroplating that is typically used. But the Monash and Rice team see their graphene film replacing polymer coatings used in metals, so the environmental aspect is less acute in this case.

Nonetheless, the Australian-U.S. research team believes that this use of graphene could change the rustproofing methods for products as varied as ocean-going vessels and electronics.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.