It sounds like something from a spy thriller movie: putting on a contact lens that gives you infrared vision without the need for a bulky contraption that covers your face. But now, thanks to research at the University of Michigan, such a contact lens is a real possibility.

The Michigan researchers turned to the optical capabilities of graphene to create their infrared contact lens. IBM last year demonstrated some of the photoconductivity mechanisms of graphene that make it an attractive infrared detector.

Graphene is capable of detecting the entire infrared spectrum, with visible and ultraviolet light thrown in. But where graphene giveth, it also taketh away. Because graphene is only one-atom thick, it can absorb only 2.3 percent of the light that hits it. This is not enough to generate an electrical signal, and without a signal it can’t operate as a infrared sensor.

"The challenge for the current generation of graphene-based detectors is that their sensitivity is typically very poor," said Zhaohui Zhong, assistant professor at the University of Michigan, in a press release. "It's a hundred to a thousand times lower than what a commercial device would require."

In research that was published in the journal Nature Nanotechnology ("Graphene photodetectors with ultra-broadband and high responsivity at room temperature"), the Michigan researchers devised a new method for generating the electrical signal. Instead of trying to measure the electrons that are released when the light strikes the material, they amplified an electrical current that is near the electrical signals generated by the incoming light.

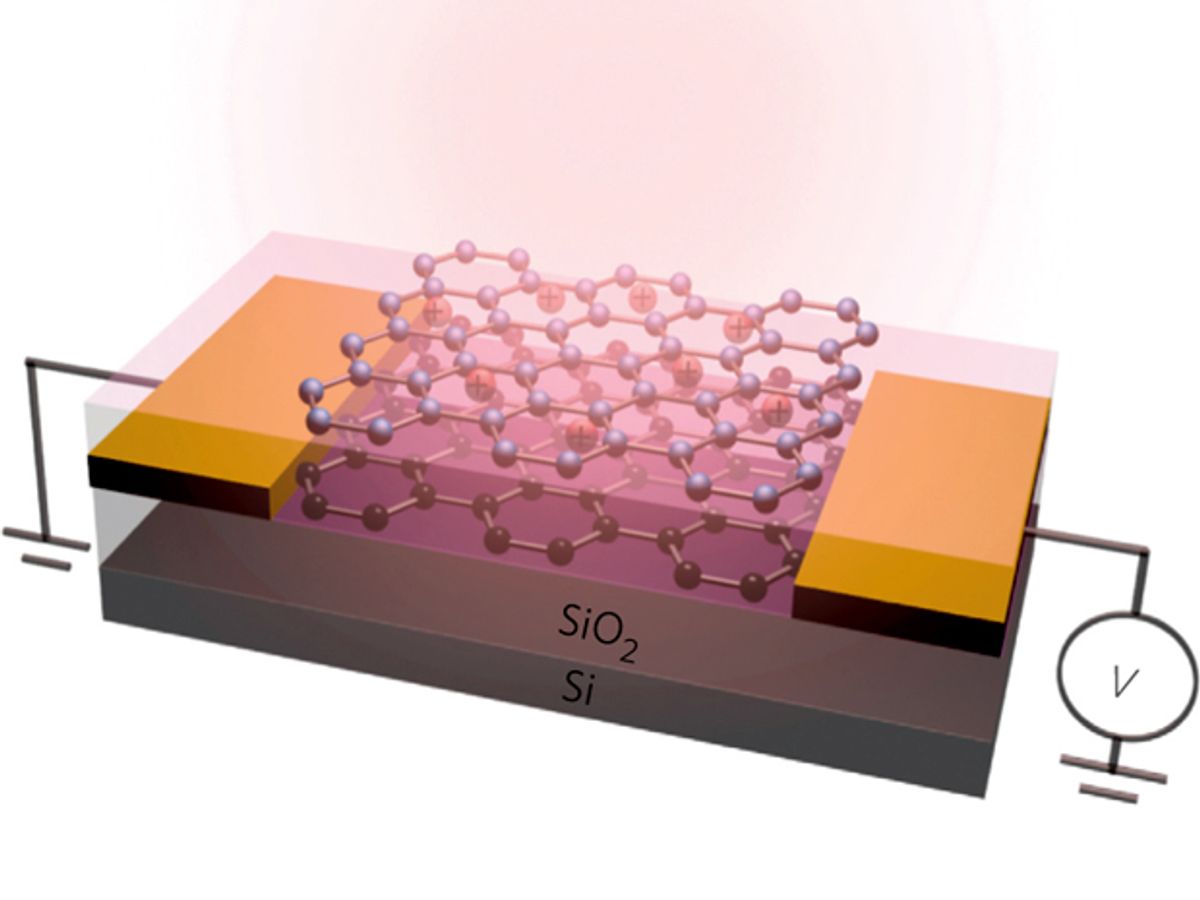

To achieve this amplification, the researchers started by sandwiching an insulator between two sheets of graphene. The bottom sheet has an electrical current running through it. When light hits the top sheet, electrons are freed and positively charged electron holes are generated. The electrons are able to perform a quantum tunneling effect through the insulator layer, which would be impenetrable in classical physics.

The electron holes that are left behind in the top layer generate an electric field that impacts the way electricity flows through the bottom layer. By measuring this change in the flow of current in the bottom layer, the researchers could derive just how much light hit the top layer.

This device has very nearly the same sensitivity as cooled mid-infrared detectors, but achieves it at room temperature. The researchers have already been able to produce infrared sensors the size of a pinky nail, or a standard contact lens.

"If we integrate it with a contact lens or other wearable electronics, it expands your vision," Zhong said in the release. "It provides you another way of interacting with your environment."

Most of us are familiar with the military applications of infrared vision, which allows the soldiers to see in the dark. But the technology also has medical applications such as letting doctors monitor blood flow.

Whether the ability to see in the infrared is an attractive feature for the rest of us remains to be seen. But that may become a possibility since the fundamental mechanism underlying the technology could become a mechanism for other material and device platforms. Is infrared vision mode for Google Glass in the offing?

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.