Perovskite is the new buzzword in photovoltaics. And graphene is the buzzword for just about every other high-tech application, including photovoltaics.

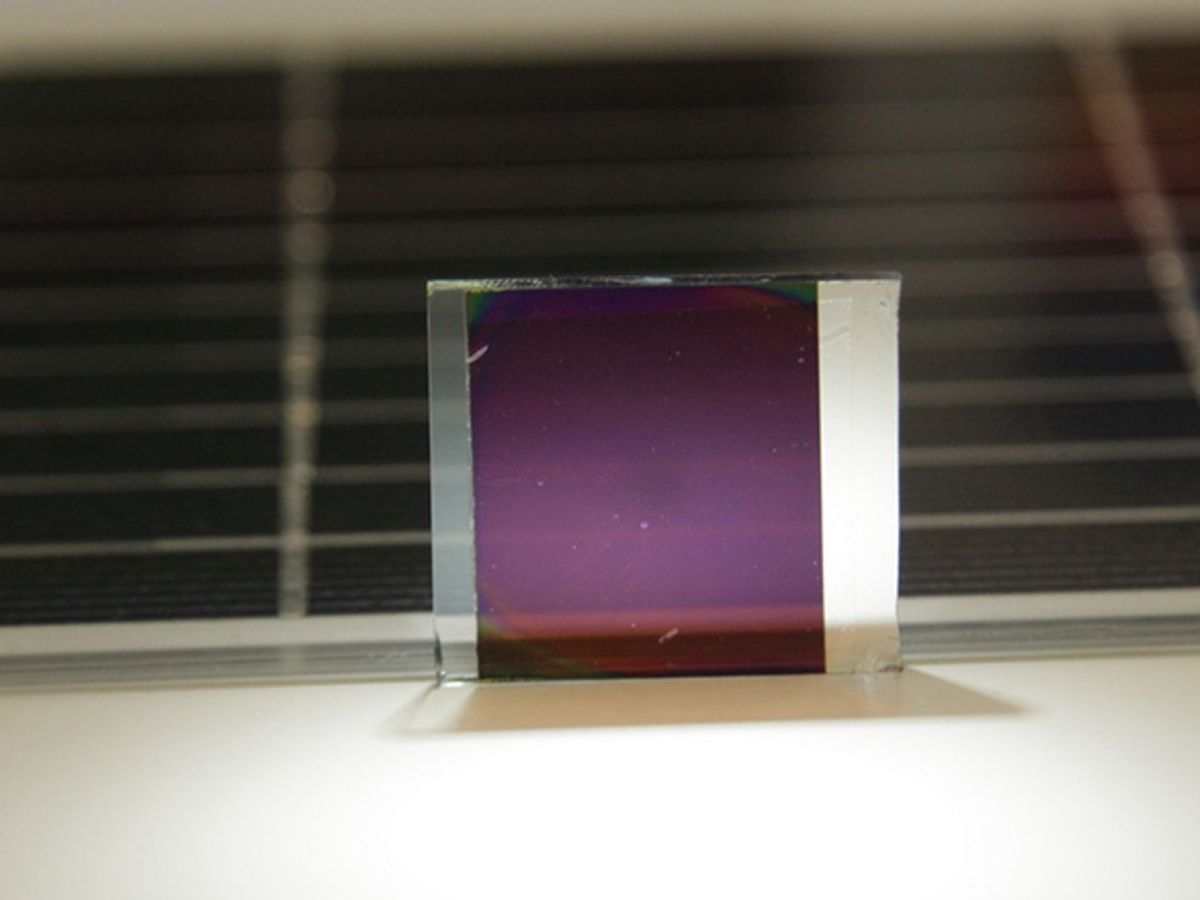

Now researchers at Hong Kong Polytechnic University have combined these two materials to make a semi-transparent solar cell capable of power conversion efficiencies around 12 percent, a significant improvement over the roughly 7-percent efficiency of traditional semi-transparent solar cells.

The semi-transparent design of these solar cells means that they can absorb light from both sides and could allow them to be used as windows that serve the dual function of letting light into a building and generating electricity.

In the design of the Hong Kong researchers’ solar cell, the perovskite serves as active layer for harvesting the light, and the graphene acts as the transparent electrode material. Graphene has long been pursued as a potential replacement for indium tin oxide (ITO) as a transparent electrode material for displays.

Here again, graphene’s transparency, high conductivity, and potentially low cost seemed attractive to the researchers. The researchers improved on the conductivity of the graphene by coating it with a thin layer of a polymer that also served as an adhesion layer to the perovskite active layer during the lamination process.

The researchers were able to improve the energy conversion capability of the solar cells by employing a multi-layer chemical vapor deposition process in which the graphene formed the top transparent electrodes. This approach maintained the transparency of the electrodes while increasing their sheet resistance.

A big concern for the researchers was lowering costs. They claim that their solar cells cost less than US$.06/watt, which they reckon is more than a 50 percent reduction in the costs of silicon solar cells. They believe that the whole process is ripe for scaling up because the mechanical flexibility of the graphene enables the possibility of roll-to-roll processing.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.