Engineering the 10 000-Year Clock

The Clock of the Long Now moves from thought experiment to actual timepiece

The year is 12011. Two hikers cut through a stretch of cactus-filled desert outside what was once the small town of Van Horn, near the Mexican border, in West Texas. After walking for the better part of a day under a relentless sun, they struggle up a craggy limestone ridge. Finally they come to an opening in the rock, the mouth of what appears to be a long, deep tunnel.

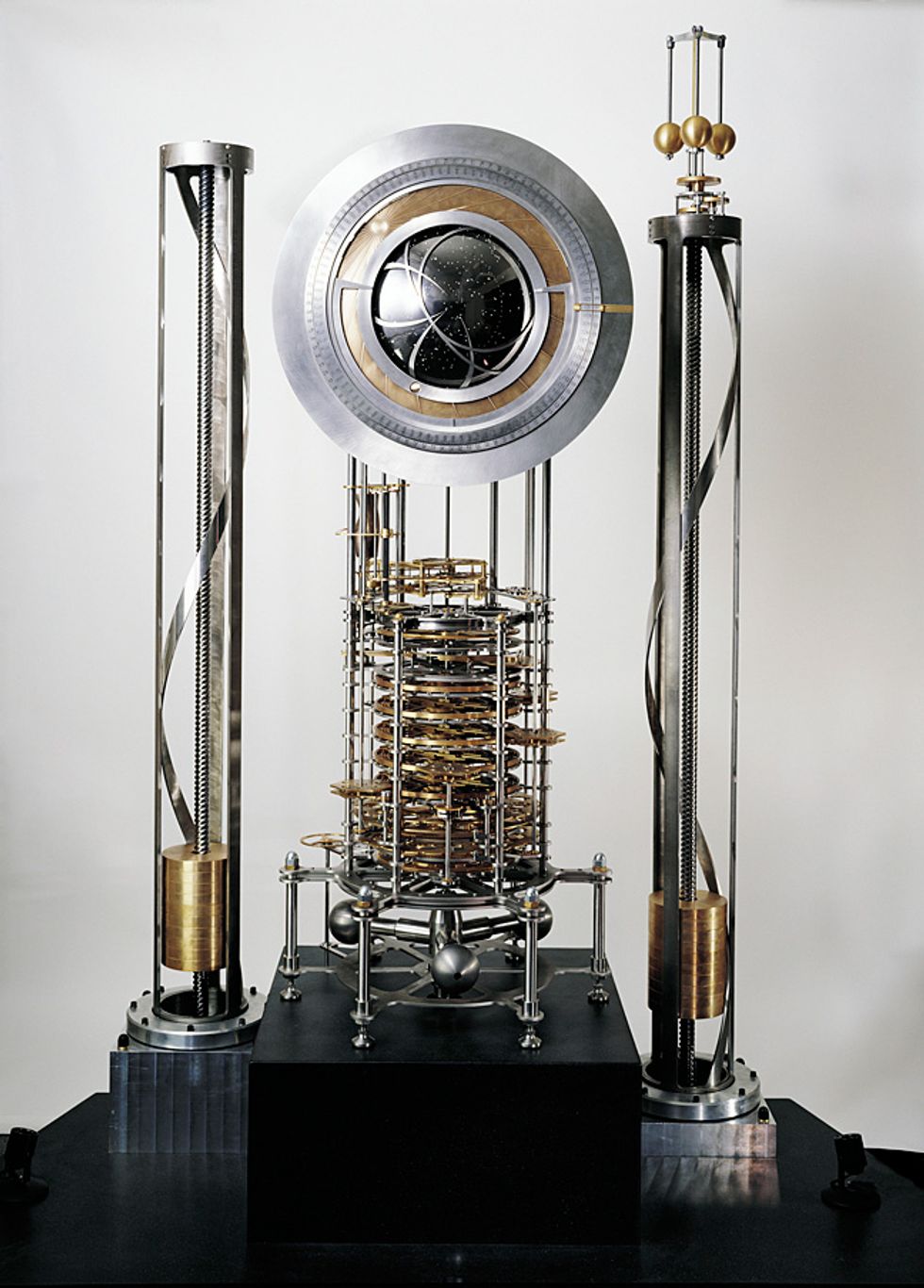

As they head into the shadows, not quite knowing where the tunnel will lead, the sudden darkness and the drop in temperature startle their senses. After a few minutes the hikers reach a cool chamber dimly lit from above. A tall column of strange shiny metal gears and rods rises hundreds of meters above them. Steps cut into the walls spiral upward, and the hikers ascend until they reach a platform. A black globe suspended above depicts the night sky, encircled by metal disks that indicate the year and the century.

A giant metal wheel sits in the middle of the platform, and the visitors each grasp a handle that juts out from its smooth edges. For the next several hours, they push and walk and push and walk in a circle, methodically, silently, until the wheel will turn no further. Exhausted, they rest on the platform and drift off to sleep. At noon the next day, they're suddenly awakened by the ethereal tones of chiming bells.

It sounds like science fiction, but this is the real vision for the 10 000-Year Clock, a monument-size mechanical clock designed to measure time for 10 millennia. Danny Hillis, an electrical engineer with three degrees from MIT who pioneered parallel supercomputers at Thinking Machines Corp., worked for Walt Disney Imagineering, and then cofounded the consultancy Applied Minds, dreamed up the project in 1995 to get people thinking more about the distant future. But the clock is no longer just a thought experiment. In a cluttered machine shop near a Starbucks in San Rafael, Calif., it's finally ticking to life.

This clock, the flagship project of Hillis's Long Now Foundation, is a wonder of mechanical engineering. Over the course of its 10 000-year life span, it will be able to power itself enough to keep time, synchronize that timekeeping with the sun, and randomly generate unique melodies on its chimes so that visitors will never hear the same tune twice. And it will do so entirely without electricity. Think of it as "the slowest computer in the world," says project manager Alexander Rose.

With funding from Jeff Bezos, the billionaire founder of Amazon.com, three teams of engineers in San Francisco, Seattle, and Texas have been working through the complexities of the design, including how to keep the clock ticking and how to ensure that its components will hold up through the millennia. Meanwhile, a construction crew in Texas has been blasting and digging through limestone to create the tunnel. In Washington state, engineers at Seattle Solstice are refining a giant stonecutting robot that will eventually be shipped to Texas and deployed inside the mountain, to etch the spiral staircase directly into the rock. "This is a project of a bunch of engineers," says Rose. "And building a big physical thing is just cool."

Still, the designers believe there's much more to the project than just geek chic. A clock that's meant to last for 10 000 years poses a fundamental challenge for a speed-obsessed age: How do you engineer something for the very distant future and get people to care about it today?

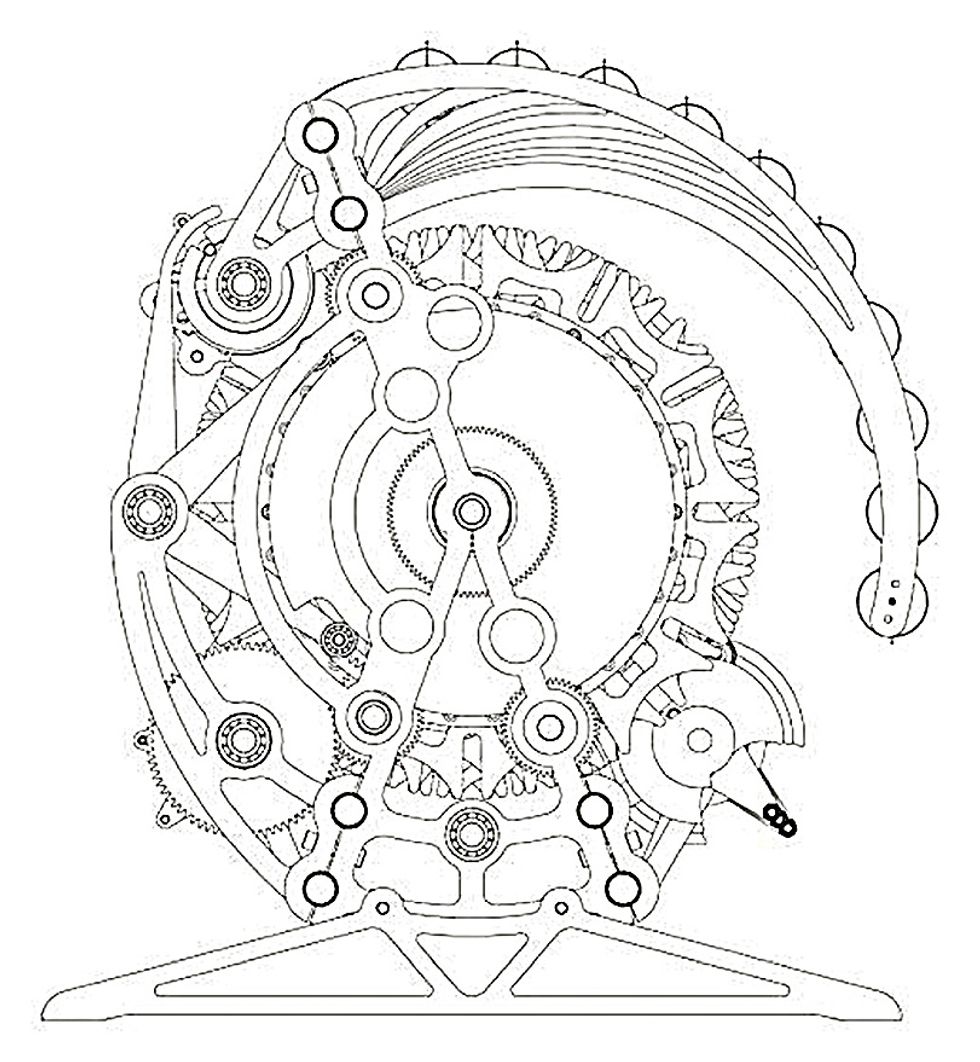

On a bright blue morning in February, I drove to the San Rafael shop with Rose to see the first assembled piece of the clock in action: several 2.4-meter-wide gears for the chime generator, one of the largest and most complex parts of the clock. Over the lifetime of the clock, the chime generator will ring a series of 10 bells in a different arrangement each time.

"I haven't seen it turn on yet," says Rose, tall and chrome-domed, dressed in a black polo shirt and khaki pants. "Baptism by fire." He flips a switch, and he and I watch the giant stainless-steel gears spin silently. I picture those future hikers deep inside the mountain, waking up to the sound of bells.

But what's the point of building something to last 10 000 years? Hillis says he chose that time span because that's about how long human technology has been around. One inspiration came from a possibly apocryphal tale of a forward-looking architect. According to the myth, back in 1386, the builder of the University of Oxford's New College planted some oak trees [PDF]. The purpose was to have wood that could be used to replace the oak beams of the college's great dining hall hundreds of years in the future.

For an engineer who had built his career on making fast machines, Hillis found this story of forethought striking. Living in an increasingly accelerated culture, he thought, was eroding our ability to think concretely about the future. "Why bother making plans when everything will change?" he wrote in a 1995 manifesto. Building an ageless clock, Hillis suggested, was a way to bring really long-term thinking back.

He took his idea to a private mailing list that included future-minded thinkers such as Stewart Brand, founder of the WELL (the Whole Earth 'Lectronic Link) online community, and electronic musician Brian Eno. The idea captivated the group, and Hillis began to consider more seriously how his clock might actually get built. In 1997, after starting the Long Now Foundation, he began to work on the clock in earnest with Rose, a Carnegie Mellon–educated industrial designer whose eclectic résumé includes stints as artist in residence at Silicon Graphics and designer of championship combat robots.

Like Hillis, Rose saw the urgency of the idea. Society needs to think long term or risk failing to appreciate such century-spanning problems as climate change and deforestation, Rose told me. The basic notion may have been a quick sell, but actually building the clock, he and Hillis knew, would be immensely difficult. As Hillis wrote in his essay, "My engineering friends worry about the power source: solar, water, nuclear, geothermal, diffusion, or tidal? My entrepreneurial friends muse about how to make it financially self-sustaining."

The money turned out to be the easy part, because the clock had attracted a formidable believer: Amazon's Bezos, who calls himself "the first steward" of the project. Bezos was struck by the clock's big idea. "If you read my 1997 shareholder letter (PDF) [the year Amazon.com went public], it's all about the long term," Bezos tells me. "And so this philosophy, this ability to use long-term thinking to accomplish important things, is a common thread in everything I'm involved in." This includes Blue Origin, his private spaceflight company. The clock is being built on a ridge that overlooks Blue Origin's headquarters.

Bezos, who got his undergraduate degree in electrical engineering and computer science from Princeton, was also drawn to the project by the sheer geeky quality of the thing. "It's a challenging engineering problem and so fun in its own right," he says.

Bezos is footing the bill for the clock's installation near the tiny town of Van Horn. Hillis and Rose hope this clock will be the first of several at different sites. (Small-scale prototypes of the clock already exist, including one that's now housed at the Science Museum in London.) Although the budget for the Texas project has not been officially disclosed, a recent article in Wired put it at US $42 million. Given the highly skilled staff, the high-tech construction and machining equipment, and the rarefied raw materials involved, that seems about right. But Bezos bristles at the notion that his investment might be perceived as frivolous. "Symbols are important," he says.

If you accept that premise, then you'll understand why Hillis and Rose's first concern wasn't sketching out the clock's innards. Instead, they obsessed over how people would experience the clock. They wanted it to be as engaging as possible, "to make someone care about it in 10 000 years," Hillis says.

"We spent more time debating the aesthetics of a given part and how humans will interact with it than any other thing," says Rose. "What is the day like as they walk through this architectural-scale clock mechanism?"

For inspiration, the team looked backward—to enduring ancient monuments like the Egyptian pyramids and Stonehenge. They also looked to the present—to theme park rides, such as those Hillis designed during his time as vice president of R&D for Walt Disney Imagineering. They realized that what each of these very different entities has in common is that the visitor experiences it as a rite of passage.

Hillis has spent the past seven years working with Rose and other members of the team to design what he calls the "plotline" of the clock. First, they wanted to ensure that visitors would be vested in the journey. That meant building the clock in a faraway, hard-to-reach place, somewhere requiring a real commitment to visit. (The site they chose indeed qualifies—for now. But it's anyone's guess what this place will be like in 10 000 years.)

Even after the intrepid explorers of the future reach the site, the drama of their journey would continue to unfold as they enter the mountain, snake through tunnels, and climb up the spiral steps past the clock gears. Finally, they would arrive at the chosen spot, where they would wind the chime generator and hear the bells ring.

But what if you were the first person to visit the clock in centuries, or even millennia? Given the vagaries of human history, it's reasonable to expect that people might one day forget the clock even exists. So for the sake of the wayward traveler who just happens upon the clock by accident, the operation had to be obvious just from looking at it.

"Someone who looks at a part must be able to figure out what to do," Rose says. "People need to be able to stumble across it and understand how it works and how to maintain it." He and Hillis call this quality "transparency."

An electronic clock was therefore out of the question: It wasn't sufficiently transparent. Instead, they decided to make the clock entirely mechanical—even the digital computer that generates the melody of the clock's 10 chimes. The chime-generating computer uses a phased series of twenty 2.4-meter-diameter gears, called Geneva wheels, to produce up to 3.5 million unique sequences of chimes.

Although much of the clockwork is similar to the workings of a standard grandfather clock, it differs from an ordinary analog gear-driven clock in a few key ways. For one thing, it will be the largest clock ever built. And instead of having a pendulum that counts off each second, the clock's pendulum has a base of 10 seconds. So it will tick at one-tenth the speed of a regular clock, which should help its gears, bearings, and other components last at least 10 times as long. And rather than having a 12-hour face, the clock will display the positions of the stars on a black globe, surrounded by dials showing the year, the positions of the sun and moon, and other astronomical data.

The clock is being designed modularly, so visitors will be able to see how the various parts go together. Working in modules has the added advantage of letting the engineers tweak different elements of the design without having to start from scratch each time. They are also discussing the possibility of including some kind of instruction manual, likely in the form of photographs or diagrams. They haven't yet decided, though, where to put the instructions or even how to alert people 10 000 years from now that the clock exists.

Once they'd settled on the narrative arc of the clock experience, Hillis says, "then it's just a lot of engineering." Despite his flip response, the clock's design has been about as thoroughly thought out as that of a Formula One race car.

Hillis and Rose could find no precedents for what they wanted to do. "Nothing else is built to last this long," Rose told me. He had just returned from the Svalbard Global Seed Vault, in Norway, where millions of seeds from around the world are now being stored in a remote, highly protected underground bunker as a hedge against climate change and human conflict. Rose also considered the design of nuclear-waste storage facilities, which are built to last for centuries or longer. But neither of these constructs is a working machine, he explains.

Even seemingly simple questions proved difficult to answer, such as: What should the clock be made of? The team needed materials that could stand up to thousands of years of wear and tear, yet few studies could shed light on the matter. For insights, they looked at the 11 000-year-old tower of Jericho, believed to be the oldest existing building in the world. They discovered that the mortar's high silica content contributed to its longevity. The team is now culling similar material from a marble mine in Texas.

For the clock's components, the team has been selecting durable materials such as stainless steel, titanium, and ceramic, whose longevity can be gauged through high-temperature testing. "How they behave at a high temperature is a good indication of how they will perform over a long period of time," Hillis says.

Consider the chime generator. The gears are made of type 316L stainless steel, a marine-grade alloy that is extremely resistant to corrosion. "It has been tested in saltwater environments and accelerated aging systems for almost a century now," explains Rose. "Like all things it will eventually oxidize, but it does so at a known rate that is within our parameters."

There was a concern, however, that over the centuries the clock's components might weld together if everything were made from the same material. So most of the pinion gears, as well as the pendulum and encasement, will be made of titanium. Many of the bearings, meanwhile, will be made from silicon nitride, a ceramic.

The bearings will have unusually rigorous demands placed on them: Although they'll be protected by dust shields, they'll still have to hold up for 10 million slow speed cycles without lubrication. The closest real-life parallel is the bearings in satellites, says Rose, and those have only a 20-year operational life. So far, the group's testing shows that the gears won't gum up from extended use. But 10 000 years is a long time.

"No one has tested them the way we need them tested," Rose says with a sigh. "No one has used titanium against stainless steel for such long periods of time."

Selecting the right materials is only one piece of the puzzle. There's also the matter of keeping the clock ticking and telling the correct time. Because, really, what's the point of a clock if it can't tell time?

To maintain the clock's accuracy, Hillis and Rose had to figure out a way to somehow sync their clock, buried deep within a mountain, with the outside world. In earlier designs, they considered a solar synchronizer: A beam of sunlight would pass through a slot in the top of the clock at noon, heating up and contracting a piece of nickel titanium shape-memory wire; the wire would act as a mechanical trigger, resetting any error that had crept into the timekeeping since the previous day.

It's a clever idea, one of many the team has devised. In total, they have 10 U.S. patents on the clock, including the winding tower, the clock face, and the solar-triggering mechanism. "We're probably the only ones patenting weird clock esoterica," Rose says.

The problem with memory wire, as with the use of electronics, was the lack of transparency. "Nickel titanium can last, but it's effectively a magic material," Rose says. "It would be difficult to replicate it in the future if someone needed to remake that part."

Instead, the sun could be exploited in two different ways. "The most promising design we're looking at uses two tanks of air: one near the surface of the mountain where the sun can heat it up and another that is kept cool inside the mountain," says Rose. The difference in temperature, amounting to tens of degrees, causes air to move from the hot tank to the cool one during the day; when the surface tank cools down at night, the airflow reverses. The movement of air will drive a piston or a bellows, which will ratchet up the clock's 4.5-metric-ton weights. The weights will then have enough potential energy to keep the 136-kilogram pendulum swinging for the next day.

To recalibrate the clock, the current plan is to use a titanium box that pops out one normally concave side when the air inside heats and expands at around solar noon. This will trigger a correction in the pendulum if it's swinging too quickly or too slowly.

Using these mechanisms, the clock will be able to keep track of the time. But displaying the current time, the team decided, will require visitors to wind the clock—yet another way to give the visitor's experience meaning. How long you spend winding the clock will depend on how long it has been since the last person visited: Winding it fully will take three people about 8 hours. Of course, that's assuming people 10 000 years from now will still be able to perform manual labor.

The challenge didn't end with designing the clock. The question was also where to put it. The team knew they wanted somewhere remote, to enhance the experience and because cities are so vulnerable to the ravages of war. They also figured it needed to be underground to have a shot at lasting for millennia, but not so far down that it would be below the water table. This meant putting it inside a mountain. But what kind of rock? Granite is difficult to cut, so they settled on limestone—soft, but not so soft as to easily fall apart.

The search was then on for a dry desert region with limestone mountains. They needed a cliff that was fracture free, so they could dig the tunnel, and also south facing, for solar-power generation. Sites from South America to the Middle East were considered. In 1999, the Long Now Foundation purchased some land in eastern Nevada as a possible home for the clock.

Ultimately, though, a patch of land owned by Bezos outside Van Horn, Texas, was chosen for the first clock installation. The monument will sit between two cliffs on either side of the mountain. With 150 meters of tunnels and shafts to excavate, the construction crew is using high-precision blasting and robotic mining equipment. Eventually, the clock's components will be shipped to Texas and reassembled inside the mountain. Although the project was originally slated to finish in 2001, these days there is no official schedule for completion, and the team estimates at least a few more years of construction lie ahead before the clock will be completed and opened to the public.

For all the creative deliberation, hard work, and long-term planning, there's one thought that continues to haunt these engineers. "My biggest fear is that people will destroy it on purpose," Rose says.

To help it survive, the team is making it as tamperproof as possible. Rose compares the overall design to "a ship in a bottle. Once it's built it will be hard to get it out of the space it's in." They also plan to store spare parts nearby. "We're building it to withstand being broken," he says. But even a broken clock will change the way people think, Rose adds. He recalls a recent encounter with a skeptic, who predicted that the machine would eventually be rendered inoperable "when the blood of future human sacrifices stops up the gears."

"That might be," Rose told the man. "But before you walked into this room, you weren't thinking 3000 years ahead. So it's already worked. By you and I having this conversation, it achieved its goal—and it's not even built yet."

This article originally appeared in print as “Ticking to Eternity.”

About the Author

David Kushner wonders how people will view the clock millennia from now: "I keep picturing the Neanderthals in 2001: A Space Odyssey discovering the monolith, stumbling on to this amazing thing." A Spectrum contributing editor, Kushner has written three books, including Levittown: Two Families, One Tycoon, and the Fight for Civil Rights in America's Legendary Suburb.