Skin-like wearables—sensors and other electronics that can be worn comfortably for days at a time because they stretch and feel just like skin—made a big splash at CES. But the first generation of these “electronic tattoos” are externally powered, that is, they harvest RF energy to respond to an external reader. That’s fine for a limited range of applications, when you want to make spot checks of somebody’s temperature, say.

For anything else, though, wearables need power on board—that means batteries and some way to charge them. But, to date, a power supply has represented the antithesis of soft, conforming, skinlike electronics: we don’t call an external power supply a brick for nothing.

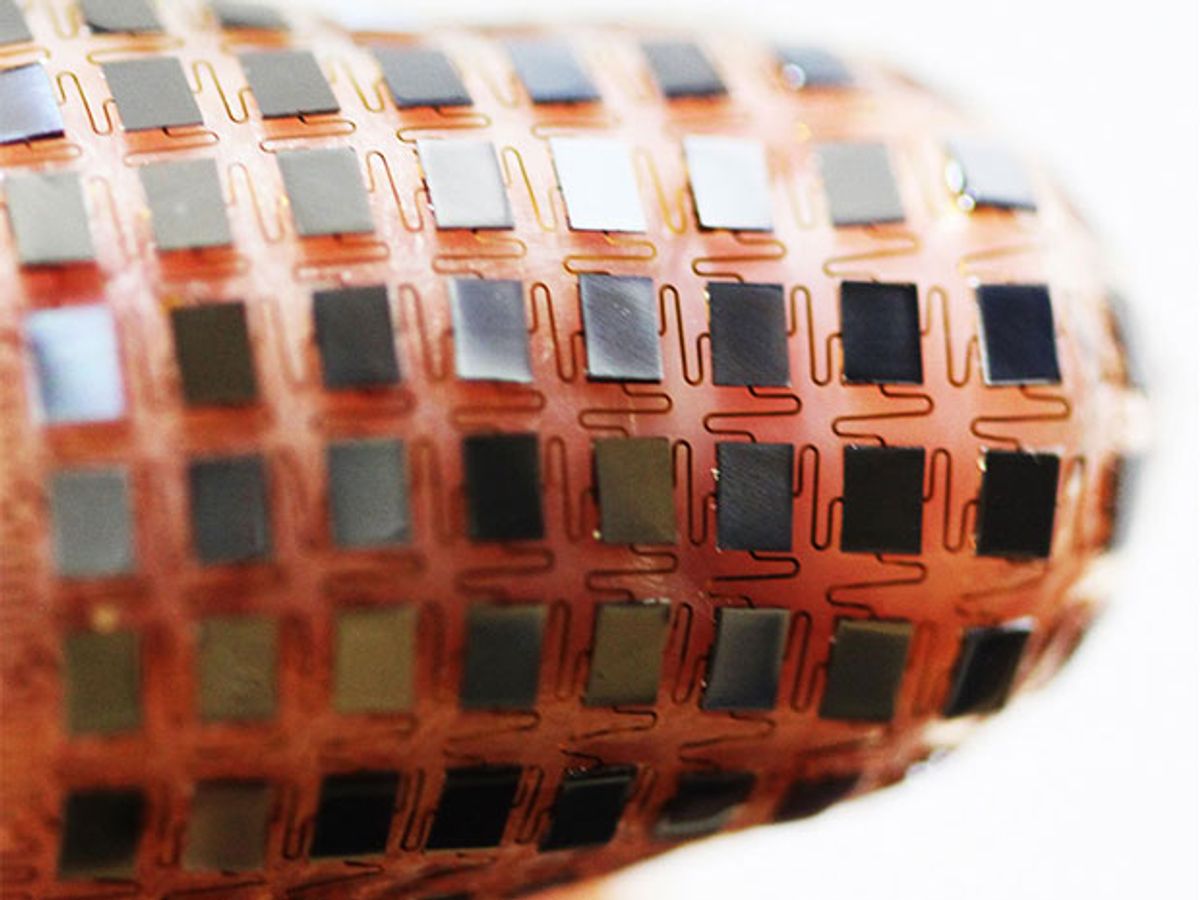

When I visited John Rogers and his fellow soft electronics researchers at the University of Illinois a year ago, they showed me some early designs for batteries; these essentially involved chopping a traditional lithium ion battery up into tiny squares and connecting them with stretchable circuits to make a battery that has some stretch and bend to it.

Today, in research published in the Proceedings of the National Academy of Sciences, Rogers describes the latest evolution of that design: a collection of thin, millimeter-scale solid state lithium-ion batteries connected using stretchable circuits to solar cells, all deposited on a flexible substrate in one layer and then folded over so that the solar cells sit on top of the batteries in the final device. He’s demonstrated the technology as part of a device that incorporates thermal sensors and NFC wireless circuitry to track and log temperature and then transmit the data as necessary. Rogers’ team tested it on volunteers biking and bathing. The thin, flexible patch can stretch up to 30 percent without affecting its solar power generating capabilities, Rogers says, which means users will barely know it’s there.

Tekla S. Perry is a senior editor at IEEE Spectrum. Based in Palo Alto, Calif., she's been covering the people, companies, and technology that make Silicon Valley a special place for more than 40 years. An IEEE member, she holds a bachelor's degree in journalism from Michigan State University.