That’s what researchers at Taiwan’s Industrial Technology Research Institute (ITRI) found out. They’d been struggling for years to figure out a way to manufacture thin, flexible, flat-screen displays. These are the stuff dreams are made of—futurists have long envisioned newspapers and maps we can fold and roll, that don’t break. They just haven’t made it to the mass market yet, they’ve been tough to manufacture cheaply.

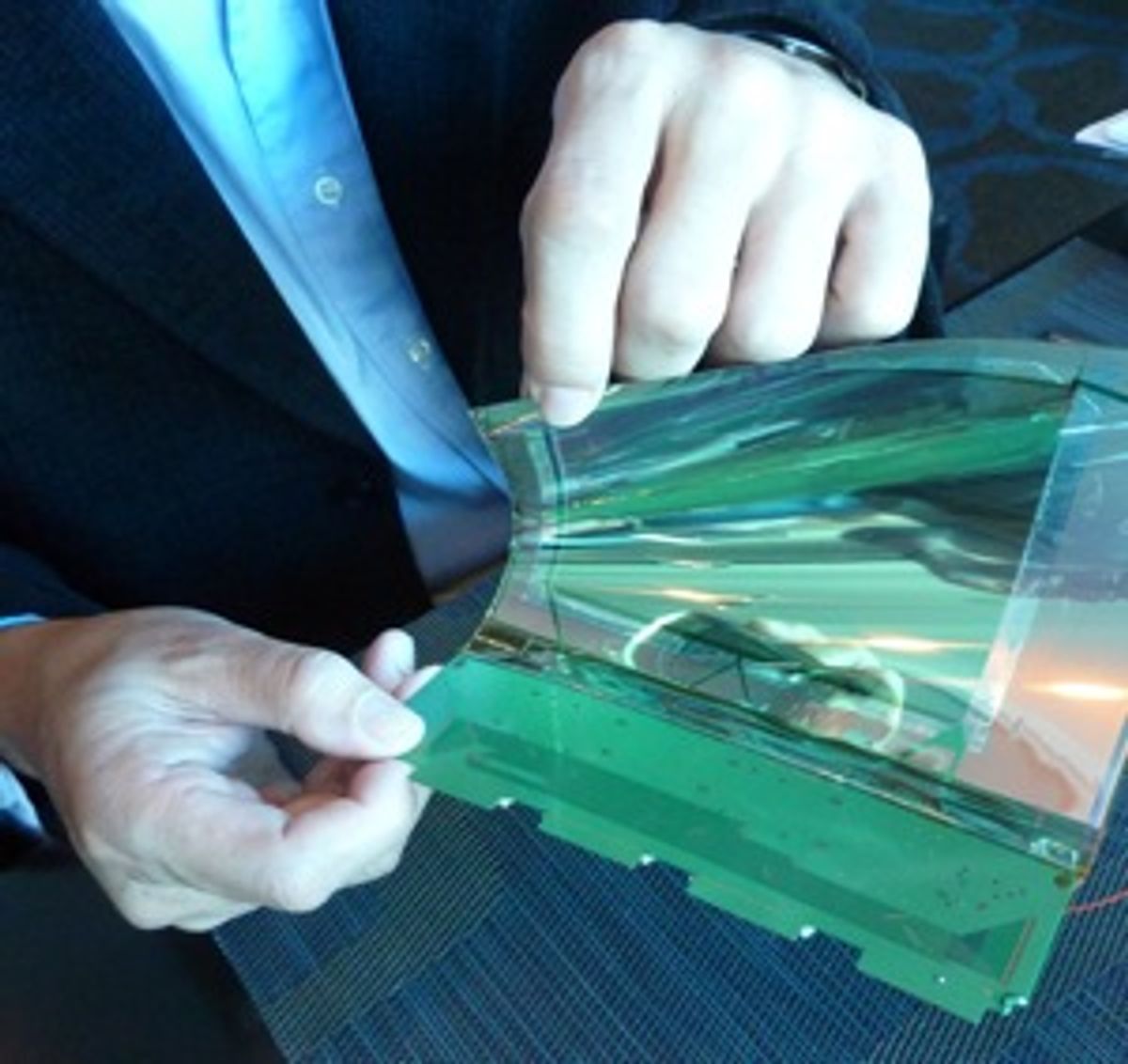

ITRI’s been working on that manufacturing issue for years. Its goal was to use standard manufacturing equipment—for OLED, LCD, or electronic paper displays—but sneak a thin layer of film in on top of the standard glass panel. Detach the film from the glass at the end of the process, and bingo, flexible display. ITRI Display Technology Center Director John Chen told me yesterday that that after successfully coming up with a transparent polymer film that could take the high heat of semiconductor manufacturing, researchers struggled to figure out a way to attach the film to glass in such a way that it would stick tight through all the manufacturing processes, but be easy to peel off at the end.

“We failed 63 times in four years,” he said.

And then one of the researchers involved in the effort went out to lunch, to a little creperie in a local market. He watched the crepe maker prepare a crepe, noticing that he didn’t spread the layer of oil to the edges of the pan. The crepe clung tightly to the edges while cooking, but, when it was done, the chef had an easy time popping it loose.

That technique, of adding what Chen calls a “debonding” layer, but not bringing it all the way to the edges of the substrate, worked just as well in display manufacturing as it did in crepe making. ITRI is being honored next week by R&D Magazine’s Top 100 Awards for the innovation. And Taiwanese company AU Optronics Corp. will be releasing a line of e-readers using this flexible display technology in 2011; Chen thinks these will be of particularly interest to K-12 educators, because of their durability.

Tekla S. Perry is a senior editor at IEEE Spectrum. Based in Palo Alto, Calif., she's been covering the people, companies, and technology that make Silicon Valley a special place for more than 40 years. An IEEE member, she holds a bachelor's degree in journalism from Michigan State University.