Flexible AC Transmission: The FACTS Machine

Flexible power electronics will make the smart grid smart

This is part of IEEE Spectrum’s special report: Top 11 Technologies of the Decade

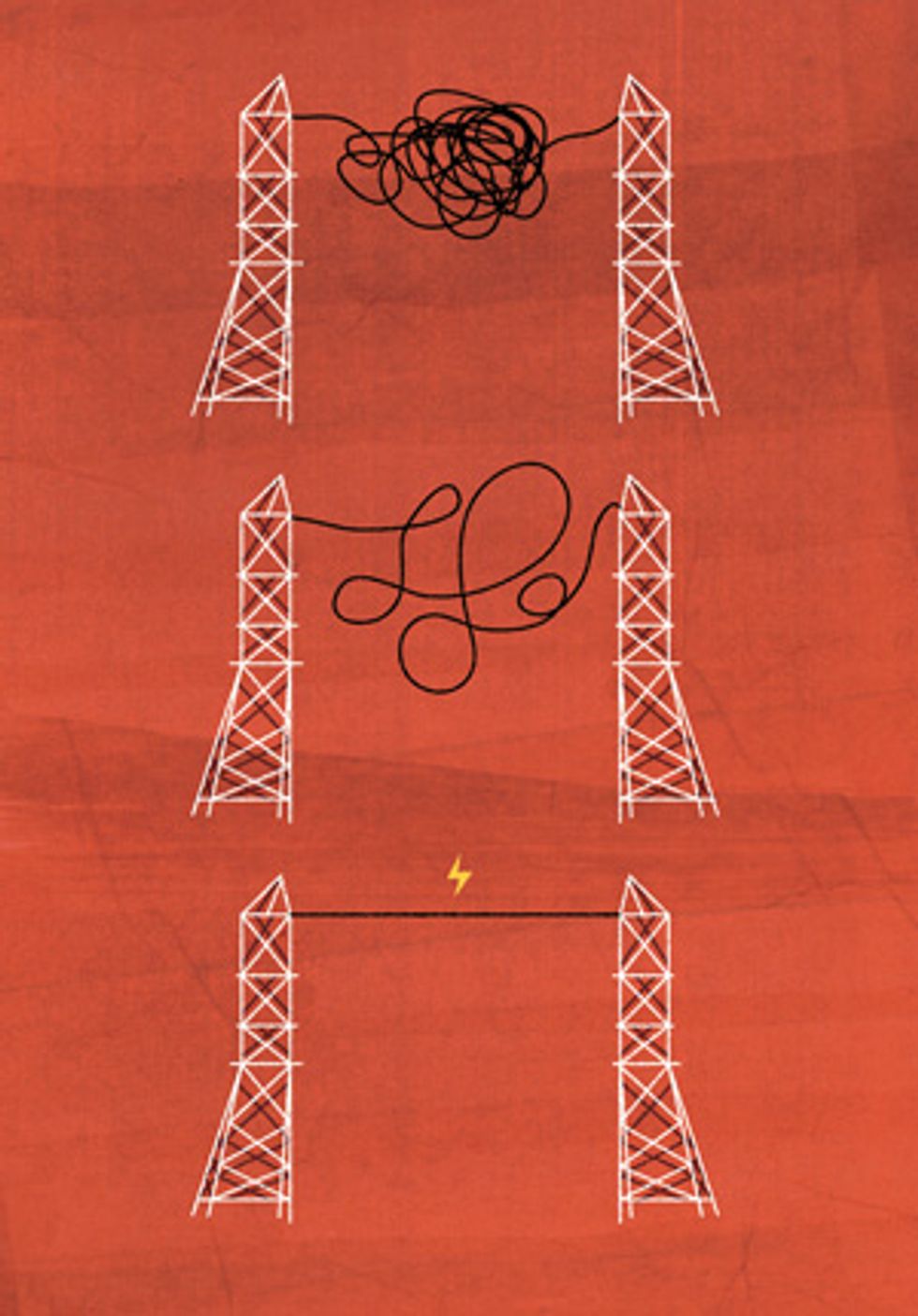

Power systems must juggle supply and demand while guaranteeing glitch-free alternating current 24/7. To deliver it, engineers once had no choice but to design grids that were as passive as the Roman aqueducts, which could carry water anywhere, so long as it went downhill. But over the past decade, a confluence of innovations, regulatory change, and sheer watt-squeezing necessity has hatched a marvelous advance, one that has begun to realize the long-standing dream of pushing current where it wouldn’t ordinarily go.

And it’s happening not a moment too soon. These flexible AC transmission systems, or FACTS, promise to save energy in a big way by making possible the smart grid, which utilities hope will reconfigure power flows in real time, maximizing throughput and minimizing losses. They should also make it possible to smoothly incorporate wind, solar, and other intrinsically intermittent sources of energy into the grid.

The key word in the FACTS acronym is the first one: flexible. Modern hydraulic engineers use pumps to push water against the force of gravity, so they save immensely on bridges and tunnels in comparison with their Roman predecessors. And think about how aeronautical engineers can manipulate control surfaces from second to second to keep aloft a plane that would otherwise be only slightly more flyable than a brick. Real-time control of power systems promises similar rewards.

FACTS proved its mettle in the 1990s in demonstrations led by the power industry’s Electric Power Research Institute (EPRI) and grid equipment manufacturers, such as GE and Zurich-based ABB. Over the past decade, FACTS has gone commercial and is “penetrating the network everywhere,” says Claes Rytoft, chief technology officer for power systems with ABB.

Applications vary widely to fit local grid conditions and challenges. “Waking giant” countries such as China and India apply FACTS to maximize the power carried by every single new transmission line they install, thus minimizing the cost of grid expansion. North American and European utilities, meanwhile, rely on FACTS primarily to tame the unruly output from wind turbines that could otherwise destabilize their congested grids. The Virginia-based consultancy NanoMarkets projects a steep growth curve for global FACTS installations, from US $330 million this year to $775 million in 2017.

COMPANY TO WATCH:

Cree,

Durham, N.C.

Efficient, high-temperature silicon carbide switches could slash power losses from silicon-based FACTS controllers by more than 50 percent. Cree leads a US $3.7 million project with the U.S. government’s ARPA-E high-risk energy R&D fund to engineer 15- to 20-kilovolt silicon carbide power modules ready for grid-scale power flows.

BET YOU

DIDN’T KNOW:

The world’s most sophisticated FACTS controller keeps New York City lit when lines upstate start to max out. The system, completed by the New York Power Authority and the Electric Power Research Institute in 2003, pulls hundreds of megawatts from NYPA’s congested Albany circuit and pushes it onto the Catskills line, a feat that has yet to be rivaled.

The first FACTS controllers emerged in the 1970s as an improved means of balancing the two types of power that coexist on AC networks: active and reactive power. Active power, the familiar watts consumed by lightbulbs and toasters, is the product of voltage and the component of an alternating current that is in phase with the voltage. The component that is out of phase multiplied by the voltage gives the reactive power, which is measured in volt-amperes reactive or VARs (or more commonly, megavars).

Reactive power is a necessary evil: It does no work, and yet you have to add it to move active power. Reactive power results when electricity flows through an inductor or a capacitor, which causes the current to lag (the inductor) or lead (the capacitor) the voltage. When the current lags, engineers refer to it as negative reactive power; when it leads, they call it positive. It’s the negative sort that tends to occur in lines, transformers, motors, and even some generators. Too much negative reactive power will cause the voltage to “sag,” a condition that can damage electrical equipment. And the damage can spread: Inadequate reactive power support during peak periods is a common contributor to cascading failures—including the 2003 blackout that toppled grids from Ottawa to Baltimore.

Typically, utilities compensate for the negative reactive power caused by inductors by injecting positive reactive power into the system. Traditionally, there are two ways of doing that: by patching banks of capacitors into a circuit to convert some of its megawatts into megavars, or by tuning the generators in conventional power stations to produce current waveforms that lead voltage. FACTS got started as a more dynamic solution, and it has become increasingly relevant as deregulation has progressively turned the electricity business into a kind of promiscuous dating game, whereby supply is married and remarried frequently to match demand, sometimes on an hourly basis, and without much regard for the capabilities of the transmission assets connecting those scattered centers of supply and demand.

By means of such matchups, FACTS allows system managers to send more power over a line than it could otherwise support. The increase can be as high as 50 percent, says Ram Adapa, a technical manager for EPRI. Stability enhancement accounts for part of the boost, allowing grid operators to operate lines closer to their thermal limits.

The heart of a modern FACTS controller is an array of solid-state switches, often coupled with capacitors. Typically, the solid-state switches open to tap power from the line and charge a capacitor; then the switches fire in sequence to create a synthetic AC waveform with precisely the needed phase difference between current and voltage. That waveform is then applied to the grid. By precisely varying the phase difference, the FACTS controller can add or subtract reactive power in fine increments.

Impressive as it is, such dynamic voltage regulation is the simplest of the FACTS grid control modes. FACTS innovators went further in the 1990s by exploiting newly developed high-power semiconductor switches that could switch at frequencies higher than the standard 50- or 60-hertz AC cycles.

With relatively advanced switches, such as insulated-gate bipolar transistors, FACTS controllers could simultaneously regulate voltage and surgically remove a variety of glitches in the AC signal. One such FACTS device, the static synchronous compensator, or statcom, has played a decisive role in the more than tenfold rise in wind power capacity worldwide over the past decade. A Siemens-built statcom, for example, is stabilizing flows from the world’s largest offshore wind farm, completed this past September, whose 100 3-megawatt wind turbines should feed enough energy to the United Kingdom’s grid during the year to supply more than 200 000 homes.

Massive wind farms barely raise an eyebrow today, but Charles Stankiewicz, executive vice president at power equipment manufacturer American Superconductor Corp., says that just a few years ago they still rattled many transmission engineers, who viewed their gusty, noisy power signal as a threat to grid stability. Stankiewicz suggests that many of the more than 70 wind farms stabilized by his firm’s FACTS controllers might never have been erected without FACTS technology. “It would have been one more excuse that allowed the electric utilities that maybe weren’t inclined to accept wind power to basically say, we’re not going to do it,” says Stankiewicz.

The most advanced FACTS go beyond stabilizing a line to reducing its apparent impedance, so grid managers can actually push more power down it. This application went commercial in 1998, when Brazil commissioned a pair of 1000-kilometer, 500-kilovolt lines to link its northern grid, replete with Amazonian hydropower, to the southern grid serving its coastal population centers. A FACTS controller near the northern end of the line simultaneously drives power and damps down destabilizing feedback signals.

The Brazilian project marked a breakthrough for AC transmission, where high impedance had previously limited lines to just a few hundred miles. The payoff was enhanced access to electricity in Brazil’s hinterland, according to Stig Nilsson, who launched EPRI’s FACTS program in the 1980s and now serves as a principal engineer with Exponent, a Menlo Park, Calif.–based consultancy. Had Brazil relied exclusively on lower-resistance high-voltage direct current (HVDC) technology to deliver power to the coast, it could not have tapped the line along the way to serve interior communities.

HVDC lines passing over as yet unelectrified regions of sub-Saharan Africa have inspired regional discord, and Nilsson says analogous concerns could upend proposals to build HVDC lines in the United States to carry wind power from the Dakotas to the Eastern Seaboard: “People are going to say, ‘Why should I allow you to send wind power through my state that I’m not even going to get access to?’”

India and China, meanwhile, have applied FACTS as a cost-cutting tool to ensure that AC lines deliver their full potential and thus reduce the number of lines required. “Instead of building three lines, they may be able to build two and put in a FACTS device,” says Nilsson.

EPRI and the New York Power Authority pushed flow control to a technical pinnacle in 2003, showing that coordinated control of two FACTS controllers could pull power off one line and drive it down another, deftly guiding power around roadblocks in the grid. However, extensive application of such advanced power control to guide flows through meshed grids will require an improvement of FACTS controllers’ efficiency and a greater recognition of their value. Grid experts expect both to happen in the years ahead.

Efficiency will rise as FACTS manufacturers integrate energy-efficient silicon carbide semiconductor switches that are being commercialized today for low-power applications and which EPRI’s Adapa expects will be available for high-voltage application within five years [see “Company to Watch”]. High-frequency silicon insulated-gate bipolar transistors (IGBTs) used in sophisticated FACTS controllers are just 92 to 94 percent efficient and require active cooling to stay below 100 to 110 °C. The result is that a large controller consumes megawatts of power. By contrast, silicon-carbide IGBTs should be 96 to 97 percent efficient and can operate at 200 °C or higher, slashing the power “tax” for FACTS-based routing of current.

The same ideas will also make HVDC more efficient, because the latest generation of HVDC converters are close technological cousins to advanced FACTS controllers. These newer HVDC systems already make possible underwater connections that are too long for AC cables. They also allow lines to reach wind farms too far offshore for AC cables and to interconnect AC systems that are adjacent but not synchronized (those of Mexico and Texas and the two main U.S. grid systems, for instance). Silicon carbide switches could make the conversion of AC lines to DC a direct competitor to FACTS as a means of assuring power flows in the heart of meshed grids.

Meanwhile, the leading alternative to both—adding new lines—is not getting any easier. New lines can take a decade to build, if they’re not NIMBYed to death by disgruntled property owners or throttled in the womb by environmental advocates, state regulators, and rival power industry players. Each new line also complicates an AC grid, adds Abdel-Aty Edris, until recently a power-electronics expert with Siemens, who helped design EPRI’s power-driving FACTS control schemes. “We already have dynamics that we don’t control and don’t even comprehend,” says Edris.

Edris’s vision is for a smart grid—both flexible and capable of handling increasing flows—via pervasive application of grid controllers, whether FACTS or HVDC. “My vision is to have a grid which is fully power-electronics integrated—a grid that’s as robust as an integrated circuit,” says Edris. Rytoft agrees: “Power electronics is the key technology for the grids of the future.”

About the Author

Peter Fairley started his career by covering the chemical industry and its environmental baggage. “So when I went freelance a decade ago,” he says, “I vowed to focus instead on solutions to problems.” While reporting, he discovered the social dimension. “By enabling developing countries, such as Brazil and India, to move electricity over long distances in the form of alternating current, FACTS can make transmission more egalitarian. The transmitted power is easy to tap, serving rural communities between the big centers.”

For all of IEEE Spectrum’s Top 11 Technologies of the Decade, visit the special report.