An experimental computer memory format uses five dimensions to store data with a density that would allow more than 300 terabytes to be crammed onto a standard optical disc. But unlike an optical disc, which is made of plastic, the experimental media is quartz glass. Researchers have long been trying to use glass as a storage material because it is far more durable than existing plastics.

A team led by optoelectronics researcher Jingyu Zhang at the University of Southampton, in the U.K., has demonstrated that information can be stored in glass by changing its birefringence, a property related to how polarized light moves through the glass (PDF).

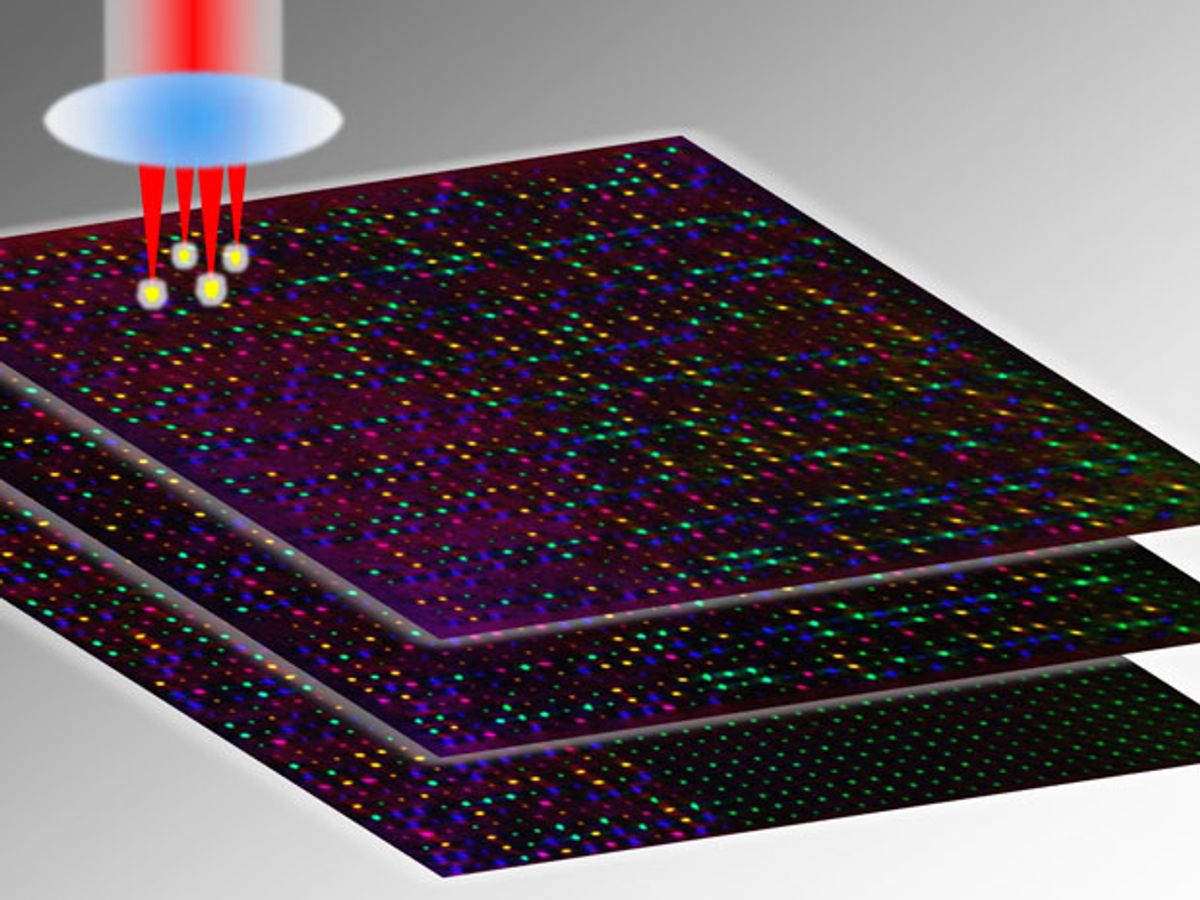

In conventional optical media, such as DVDs, you store data by burning tiny pits on one or more layers on the plastic disc, which means you're using three spatial dimensions to store information. But in Zhang's experiment, he and colleagues exploit two additional, optical dimensions.

When their data-recording laser marks the glass, it doesn’t just make a pit: it changes two parameters of the birefringence of the glass. The researchers set these parameters, called slow axis orientation and strength of retardance, by controlling the polarization and intensity of their laser beam. Add the two optical dimensions to three spatial coordinates and the result is "5D data storage," as Zhang calls it.

Previous attempts at storing data in glass consisted of burning tiny holes into the material, but that approach means that an optical microscope is required to read out the data. Zhang's goal is to write data into glass in a format readable with lasers, like existing optical discs, to keep data-reading costs down.

The writing costs will be higher, though, since changing birefringence in glass requires fine control of a laser's polarization and intensity. Earlier attempts involved rotating the laser and using an attenuator, Zhang says, but that could take several seconds between writing operations, making it far too slow for practical applications.

Instead Zhang and colleagues bounced the beam of their ultrafast writing laser off a tiny, commercially available LCD-like screen called a spatial light modulator, or SLM (see illustration below). It changes its reflectivity quickly in response to electrical charges, giving the team fine control over the intensity of the reflected beam.

Then, to control the light's polarization, the team sent the writing beam through a square panel containing 16 subsquares of different colors. Up to this point, the system has no moving parts.

But the quartz glass itself sits on a moving platform. The team achieved writing speeds of around 1 MB/s, Zhang claims. For comparison, that's about the speed of the first DVDs, and the latest flash memory devices can write a couple orders of magnitude faster.

Ultrafast lasers cost more than existing lasers, and glass costs more than the plastic used in DVDs, but Zhang says, "Our main point is that this memory can last very long. If it can last a million years . . . people will like to spend this money."

In his experiment to demonstrate the 5D method, Zhang stored a text file—the abstract of a talk he gave—onto a 4 centimeter-square blurry piece of glass. The text read:

"The high-density five dimensional data storage with ultrafast laser writing is demonstrated. The text file is recorded by polarization controlled self-assembled form birefringence and retrieved in glass opening the era of unlimited lifetime data storage."

Embedded in glass, Zhang's words should last for a very long time—perhaps much longer than in this ephemeral web page.

Images: Jingyu Zhang/University of Southampton

Lucas Laursen is a journalist covering global development by way of science and technology with special interest in energy and agriculture. He has lived in and reported from the United States, United Kingdom, Switzerland, and Mexico.