An international team of researchers from Germany and the US have fabricated for the first time a field effect transistor made of black-arsenic phosphorus.

In research published in the journal Advanced Materials, the researchers from the Technical University of Munich (TUM) and the University of Regensburg in Germany and the University of Southern California (USC) and Yale University in the United States have developed a new method for synthesizing black-arsenic phosphorous that doesn’t require the high pressure typically needed, lowering energy requirements for the process and thereby costs.

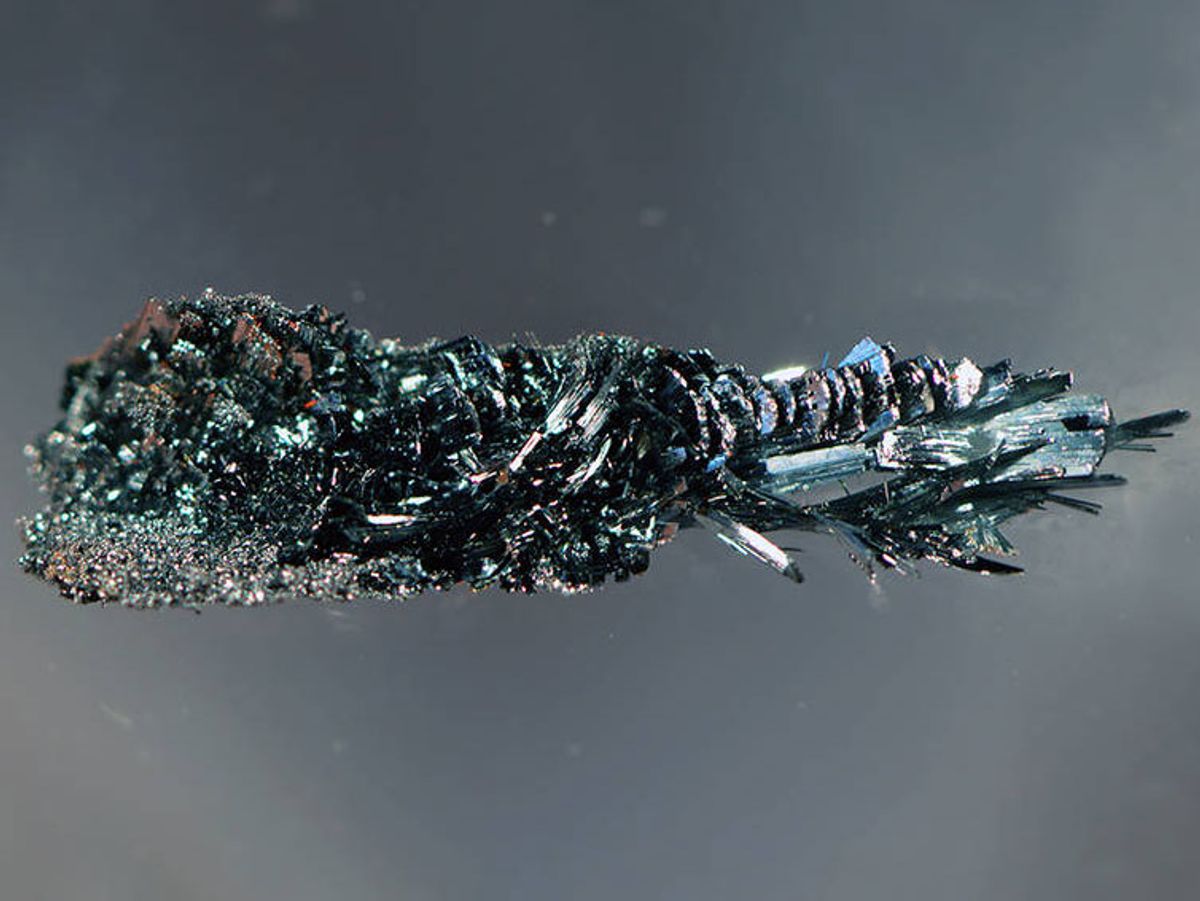

Black phosphorus has been around for about 100 years, but recently it has been synthesized as a two-dimensional material—dubbed phosphorene in reference to its two-dimensional cousin, graphene. Black phosphorus is quite attractive for electronic applications like field-effect transistors because of its inherent band gap and it is one of the few 2-D materials to be a natively p-type semiconductor.

The German/US researchers replaced individual phosphorus atoms with arsenic so that when the material reaches a concentration of 83 percent arsenic it gets an extremely small band gap of only 0.15 electron volts. As a result, the researchers believe that this material is ideally suited for sensors that can detect long wavelength infrared radiation, such as LiDAR (Light Detection and Ranging) sensors used as distance sensors in automobiles.

The gap between the valence and conduction bands does not need to be so small. Simply by adjusting the arsenic concentration, the researchers can precisely control the size of the band gap.

"This allows us to produce materials with previously unattainable electronic and optical properties in an energy window that was hitherto inaccessible," said Tom Nilges, head of the research group at TUM, in a press release.

Like graphene and other 2-D materials, the researchers expect that this material could find use in flexible electronics where its properties of strength and flexibility are far superior to brittle silicon.

Dexter Johnson is a contributing editor at IEEE Spectrum, with a focus on nanotechnology.