Building Bloodhound: The Fastest Car in the World

Jets, rockets, and computer models will help a British team break 1,600 km/h

In a suburb of Bristol, in western England, not far from the Welsh border, a band of engineers are building a machine that they hope will make the biggest jump in the century-long history of the official world land-speed record, taking it from a smidgen above the speed of sound to 1,600 kilometers (1,000 miles) per hour. That's roughly the cruising speed of a fighter aircraft, but it's considerably harder to achieve at ground level, where the atmosphere is far thicker. And there's the not-insignificant danger that the vehicle will end up plowing into the ground.

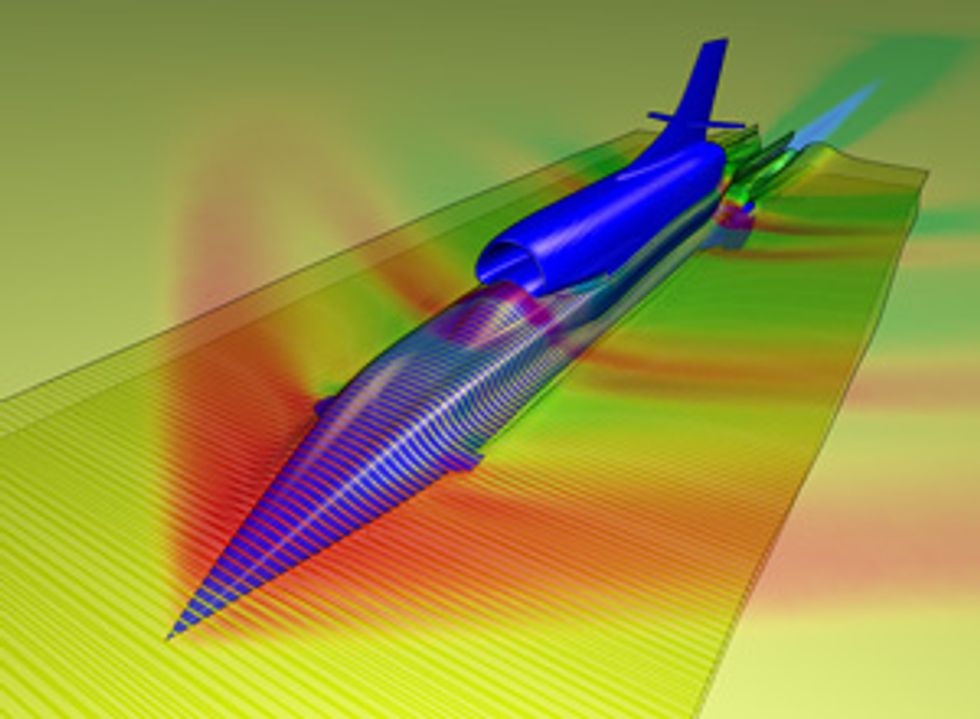

Even in the complicated business of breaking such speed records, Bloodhound represents a remarkable array of firsts in terms of technology, engineering techniques, and propulsion systems, all set to send the missile-shaped car down a nearly 20-km-long racetrack in the South African desert toward the end of this year. Perhaps the most striking of those firsts is the project's method of verifying the safety of the design. To a degree that would be unthinkable today, earlier record attempts relied on overengineering, best-guess estimates, intuition, and sheer luck. Earlier generations of engineers would often discover a car's limits with destructive testing—running it until it broke. Now modeling and data acquisition, the preferred tools for designing both aircraft and cars, are making headway in this most extreme of sports. Bloodhound is the first project of its kind to apply them. By the time the car makes its great bid for the record in South Africa, it will have done the run 1,000 times in silico.

The project is taking shape in what's known as the Doghouse, a hangarlike space that is divided down the middle. To the right as you enter is a structure that will house the control center, recovery vehicles, and testing rigs, along with the “show car," a full-scale model that has become a familiar sight at industrial exhibitions around the United Kingdom during the seven years of the project. On the left is the growing bulk of the thing itself, whose full name is Bloodhound SSC (for “supersonic car"). It was just over halfway finished when this article was being written.

At the center of Team Bloodhound are the current holders of the land-speed record: driver Andy Green (a fighter pilot now serving as a wing commander with the Royal Air Force), project director Richard Noble, and veteran aerodynamicist Ron Ayers. In 1997, Green became the first person to break the sound barrier on land, setting a record of 1,228 km/h (763 mph) in a car called Thrust SSC as it raced over the Black Rock Desert in Nevada. Noble set the previous record, hitting 1,019 km/h (633 mph) in a car named Thrust II in 1983. As with all these trials, the speeds are an average of two runs in opposite directions within a set time limit.

Project Bloodhound's first goal is to break Green's existing record before the end of 2015. The second is to take the record into new territory, hitting 1,600 km/h in 2016, after an engineering review of the 2015 runs and a possible rebuild. The third is to motivate more young people to study engineering, just as the Apollo program did for Noble's generation in the 1960s and 1970s.

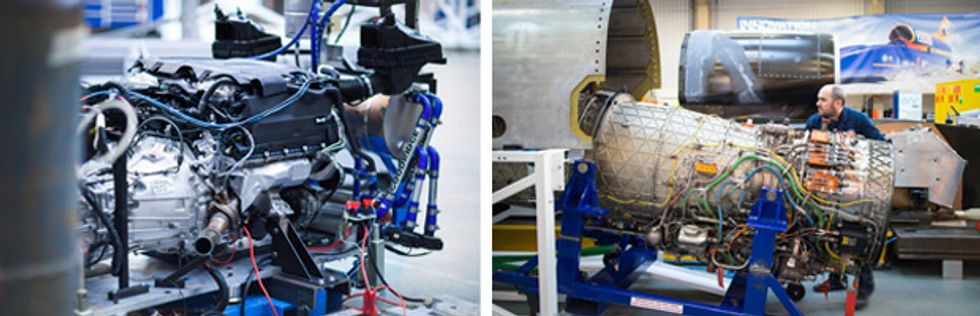

The last of these goals came about almost by accident. Bloodhound's predecessor, Thrust SSC, was powered by two jet engines—Rolls-Royce Spey turbofans, taken from a retired RAF Phantom fighter-bomber. Noble and Green knew that this arrangement wouldn't be enough to set a new record. Two engines would be too heavy, and the elderly Speys wouldn't have the necessary power. At the outset of the project, the only single jet engine with the power-to-weight ratio needed was the Rolls-Royce Eurojet EJ200, the power unit for the Typhoon fighter. And even then, it was obvious that to send it through the sound barrier the effort would have to use a second propulsion system—a rocket.

But you can't buy a new EJ200 on the open market, and you won't find any surplus units on eBay. The only way to get your hands on one is to ask very nicely. So in 2007 Green and Noble approached the U.K. Ministry of Defense, asking to do just that. They were told they could borrow one, but only if they combined the project with an educational effort.

My Jet has a Rocket

loyaltyshopping_cartlocal_librarydelete

As a result, the Bloodhound show car has toured hundreds of schools in the U.K. It has also visited many South African schools. Meanwhile, the car's runs will be public to an unprecedented extent, with data from onboard sensors streamed on the Internet in real time.

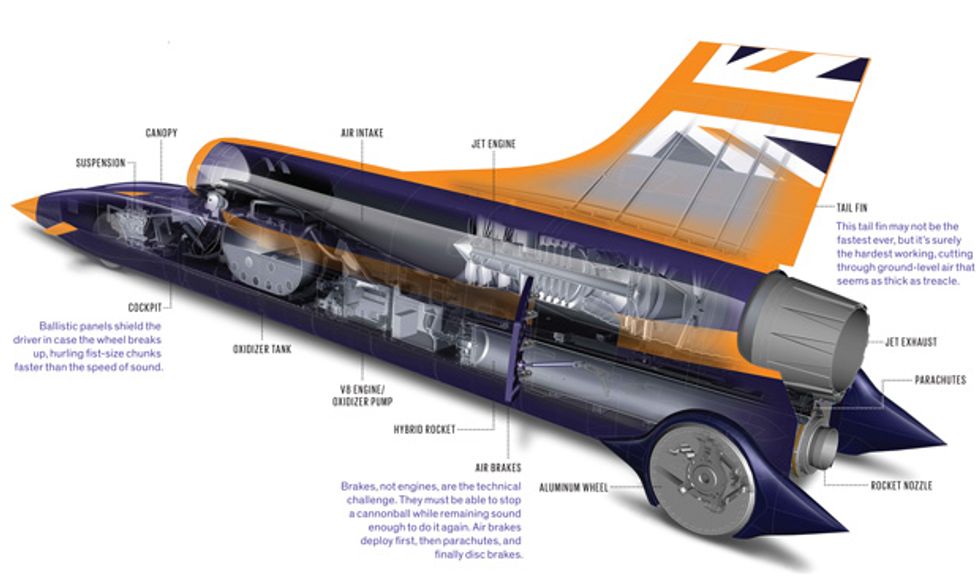

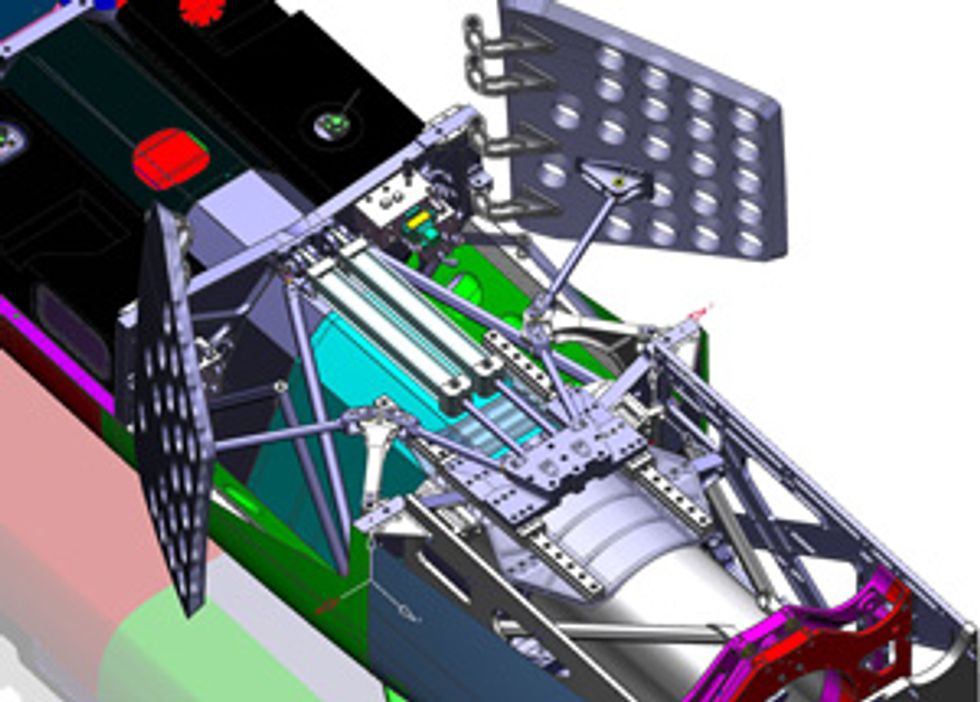

In another first, Bloodhound carries three engines. From standstill to about 650 km/h (400 mph), the EJ200 takes the strain. Above this speed, a set of rockets supplied by a Norwegian company, Nammo, will add their thrust. These are hybrid rockets, burning solid fuel—a synthetic rubber compound—using high-test hydrogen peroxide (HTP) as the oxidant. The pump squirting the HTP into the combustion chamber will be driven by the third engine, an eight-cylinder, 5.0-liter, supercharged internal-combustion engine normally found in a Jaguar.

This design combines power and controllability. The jet can be throttled up and down—an operation with which Green, as a fighter pilot, is very familiar. The hybrid rocket is also throttleable, to an extent: Its thrust is proportional to the pressure with which the HTP is pushed into the combustion chamber, and the Jaguar engine doing that can provide a range of output to achieve this. In practice, Green won't adjust the flow of oxidizer after he fires the rocket. He can shut off the HTP, though, thereby shutting down the rocket.

Bloodhound also has three braking systems. The first to deploy will be a pair of air brakes, which stick out from the sides of the car close to its rear end. These large perforated panels are operated pneumatically and are mechanically linked so that both always open to the same degree. They will slow the car down to about 1,080 km/h (670 mph), at which point Green will release two drag parachutes, similar to those used by some aircraft, to reduce speed to about 320 km/h (200 mph). From here, the car will be brought to a stop using conventional brakes attached to the front wheels.

The wheel brakes are a good example of how the demands of the project affect development. Although they will be used only in the last stages of stopping the car, the brake discs spin along with the wheels, and therefore at peak speed they will be moving at about 10,500 revolutions per minute. The team tested the brake discs used on the Typhoon fighter, but these couldn't manage the job. Neither could any carbon-fiber brake disc. Even the hardiest model put through a spin test shattered into tiny pieces as it neared the vital speed. “We had to vacuum all the bits and dust out of the test rig," recalls systems engineer Joe Holdsworth.

The only brake discs that can cope with the strain are steel, which is likely to distort but is cheap enough to be replaced if necessary.

This was one of the very few times these engineers used destructive testing to design something for Bloodhound. In marked contrast to those attempting most of the previous land-speed records, this team has used a combination of computer simulations and sensor data to test whether their designs are robust enough to cope. Thrust SSC pioneered this technique in the 1990s, but to a much smaller extent: Wind-tunnel and rocket-sled tests on models supported certain computer simulations, and the car was equipped with sensors, but far fewer than Bloodhound will carry.

Take the wheels, for example. They will be the fastest-turning wheels in the world. And when the car is traveling at 1,600 km/h, material on the rim of a wheel will experience about 50,000 g's. The wheels, which measure just under a meter across, are made of solid metal and are machined so that the rim is a shallow V shape that digs into the desert floor.

Initially, the team thought the wheels would have to be made from titanium, but a finite-element analysis (which simulates the stresses that solid structures experience) indicated that suitably forged aluminum would be strong enough. So Bloodhound's designers settled on an aerospace-grade alloy of aluminum with a light salting of zinc, copper, and manganese.

Not entirely trusting computer models for this vital component, they engineered two series of tests to confirm that aluminum wheels would work. In the first, the engineers put wheels onto a trailer carrying 3.5 metric tons of water to mimic the weight of the fully fueled car. The team then pulled the trailer across the desert where the record attempt will take place: Hakskeen Pan, in the northwestern corner of South Africa. Using a small truck as a tow vehicle, they were able to get the trailer going up to about 60 km/h—good enough for a low-speed test of the wheels' ability to bear weight.

The engineers also put the wheels into a rig that Rolls-Royce uses to test compressor discs for its jet engines. “Metal is a very uniform material, and it can be modeled quite well," says Holdsworth. “We were monitoring the stretch at the rim and the changes at the hub with a laser sensor rig, and the stretch that the [finite-element analysis] predicted matched up with what we saw, including the effects of the temperature rise from air friction."

That agreement between measurements and modeling gave Bloodhound's designers greater confidence in their computers, which they've used to design all of the structural features of the car, including its tail fin. “This is the hardest-working tail fin in history," says the engineering lead for mechanical design, Mark Elvin. “Not the fastest necessarily, but relative to a tail fin on a supersonic aircraft that flies at 45,000 feet, it's being pushed through treacle."

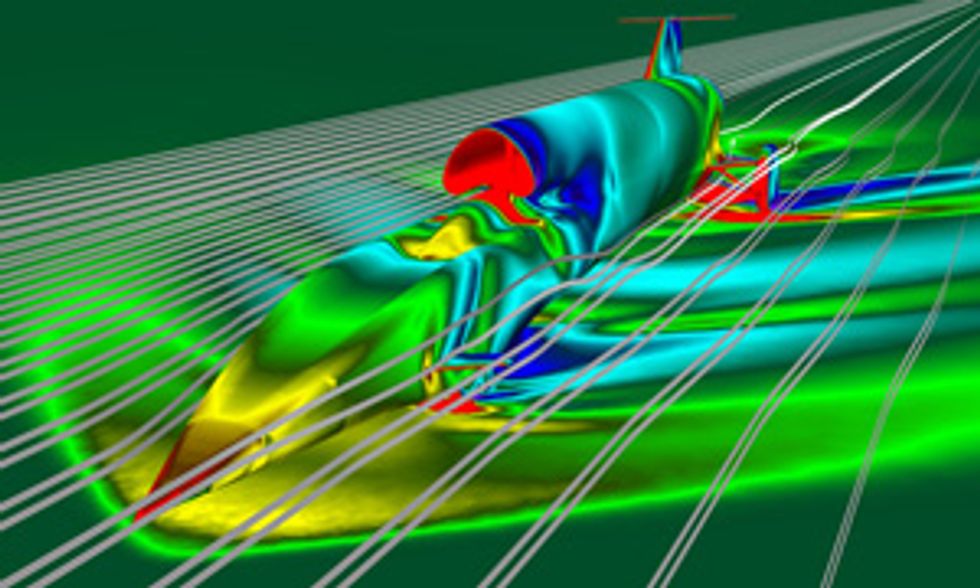

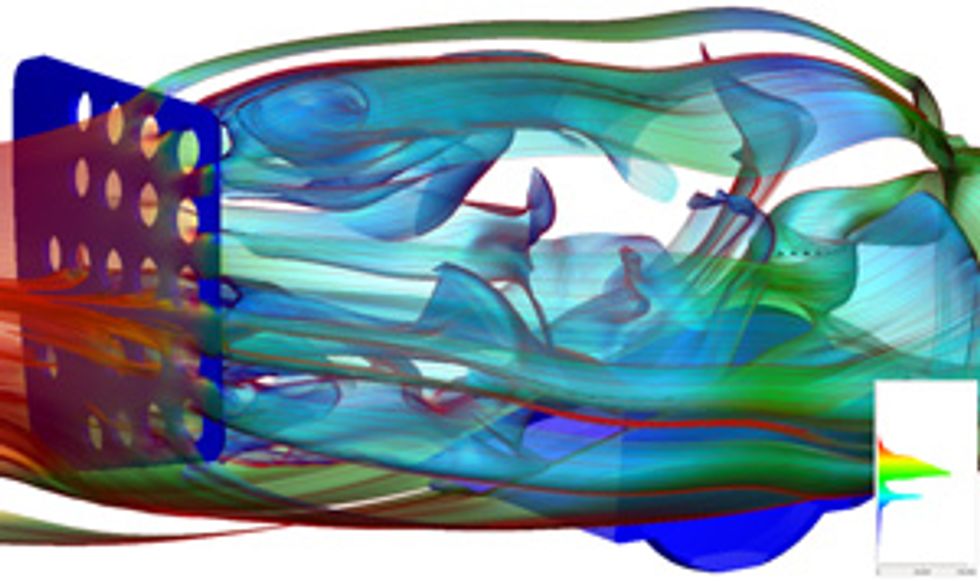

Elvin and his colleagues are using a combination of finite-element analysis and computational fluid dynamics (CFD), which models airflow and predicts the stresses it will create on the component. The results have given the team confidence that this aluminum tail fin can stay the course.

Bloodhound's entire structure—the titanium skin of the upper chassis, which is supported on aluminum ribs; the steel under chassis, designed to withstand a supersonic spray of desert gravel and sand; the carbon-fiber monocoque that surrounds the driver and forms the air intake for the EJ200—is perforated with hundreds of millimeter-wide holes. These tiny openings lead to pressure sensors fixed to the inner surface of the skin. Other sensors include a network of strain gauges placed at strategic points on the car's structure.

These sensors will, in all, collect 197 channels of data as Bloodhound runs, measuring the air pressure and the flex of the body as the car skims over the desert. “The pressure sensors are placed at zones of high transition, where the airflow changes direction," says Holdsworth. “The sensors we're using are designed for aerospace, so they're fine for pressures well above what we'll experience even at Mach 1.4, which is about 12 tons per square meter at the front of the car."

“We've even got pressure tappings inside the wheel wells, because trying to use CFD to model the airflow around a wheel spinning at 10,500 rpm—with air coming in from the front, with debris getting flung up by the wheel—is very, very difficult," Elvin adds. Yet it's critical that the engineers know what's going on. “We'll be checking that the pressure stays within the design limit, because if it doesn't, the arch will crack or burst, and all that air and debris will be flung rearwards," he says. To guard against such a calamity, Bloodhound is fitted with panels strong enough to withstand the impact of a fist-size fragment breaking off from a wheel.

Computers will download all this sensor data at the end of each run. The engineers will then compare the data with numerical simulations of the car running at the same speed to see if there are any discrepancies. “As long as we're close to what we expect, we know we'll be safe to increase the speed in the next run," says Elvin.

If the pressure sensors show greater-than-expected lift or downforce, for example, going faster could make the car take off or dig itself into the desert floor. To avoid this, the car's two sets of aerodynamic winglets can be repositioned. “We have the option to run them up or down by 5 degrees," Elvin explains. But they won't adjust automatically. Instead, the team will work out how the winglets should be positioned for a given speed, and the driver will dial in whatever is called for.

Thrust SSC used similar sensor systems, although to a much lesser extent than Bloodhound. “In the early days, the Swansea University team reran the Thrust SSC pressure sensor data through our CFD software. Because we knew that the data was good, we could use it to test our software," Elvin explains.

The data from Bloodhound's strain gauges will similarly be compared with finite-element analysis strain models. Discrepancies could well indicate regions that need reinforcement. One area where strain was a major concern for Thrust SSC was the steering: Green had to fling the steering wheel from side to side to keep the car running straight, and at one point he wrenched the wheel off the steering column entirely.

Bloodhound's steering wheel is 3-D-printed hollow titanium—light, strong, and molded to fit Green's hands; the team hopes this wheel will withstand anything, although Bloodhound is expected to track much straighter than Thrust did. Green's cockpit instruments include a display of his own design that shows speed, distance, and time to the end of the track. Constant calculation of speed and position, using GPS data and onboard sensors, will give Green a clear indication of when he must trigger the rockets, air brakes, and parachutes. “I hit the buttons, and I know I'll stop at the end of the track," he says.

Green refers to the cockpit as his office. For a few minutes, it'll be the fastest-moving workplace on the face of the earth.

About the Author

Stuart Nathan is the features editor of The Engineer, published in London. He last wrote for Spectrum in 2013, when he covered Formula E, the all-electric racing series.

- A Car That's Faster Than a Speeding Bullet - IEEE Spectrum ›

- Porsche Claims It Can Double Tesla's Fast-Charging Rate - IEEE ... ›

- The Tuatara Is The World's Fastest Production Car - IEEE Spectrum ›