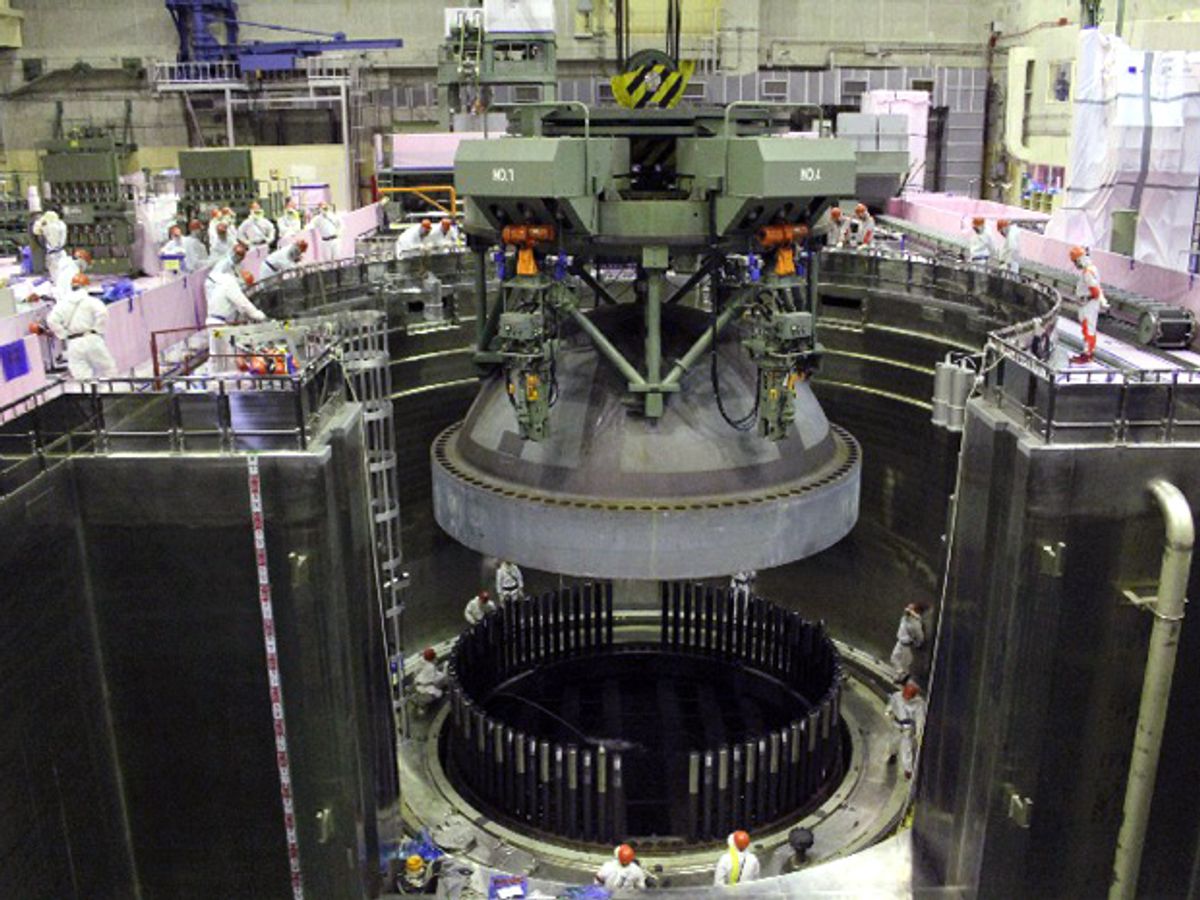

Nuclear power plants’ reactor pressure vessels (RPVs)—the massive steel jars that hold a nuclear plant’s fissioning fuel—face incessant abuse from their radioactive contents. And they must be built with extra toughness to withstand pressure and temperature swings in the event of a loss-of-cooling accident like the one that occurred at Fukushima in 2011. As the triple meltdowns at Fukushima Daiichi showed, the next layer of defense against a nuclear release—the so-called containment vessels—can not be counted on to actually contain molten nuclear fuel that breaches the RPV.

Nuclear safety authorities have recently discovered weaknesses in several RPVs, and their contrasting responses suggest that the ultimate lessons from Fukushima are still sinking into international nuclear power culture—especially in the United States, where the Nuclear Regulatory Commission (NRC) is resisting calls to mandate tougher inspection of RPVs.

Broadly speaking, European regulators have ordered operators to do more to improve safety post-Fukushima than the NRC has. France, for example, is mandating four times as much investment than the U.S. in upgrades such as reinforced bunkers, back-up power, and emergency cooling systems, according to industry estimates cited by Bloomberg Business nuclear safety correspondent Jonathan Tirone.

In February, U.S. diplomats worked to defeat a European initiative to strengthen the Convention on Nuclear Safety, created after the 1986 Chernobyl meltdown. The Europeans wanted the currently voluntary treaty to set mandatory safety standards—a proposal that the United States apparently judged too threatening for U.S. nuclear operators struggling to compete amidst a glut of cheap power generated from natural gas. “The U.S. ...worried that the proposal would have required shutting down their plants,” according to Mark Hibbs, senior associate in the Carnegie Endowment for International Peace.

Response to the RPV quagmires is a microcosm of the apparent divergence in U.S. and European nuclear safety postures. The issues relate to both new and old plants. One centers on thousands of tiny flakes of hydrogen detected in 2012 within the steel of the 40-year-old RPVs at two power stations operated by Belgian utility Electrabel. The second came to light last week when Paris-based nuclear engineering giant AREVA revealed that the RPV it forged for France’s new nuclear station, under construction in Normandy, had flunked tests mandated by France’s nuclear regulator.

In both the Belgian and French cases, nuclear authorities are facing down immense economic and political pressures to err on the side of caution. The new nuclear station in Normandy, under scrutiny by France’s Autorité de sûreté nucléaire, is already three years behind schedule and more than €5 billion ($5.3 billion) over budget.

Flamanville is one of two troubled European Pressurized Reactor (EPR) projects in Europe that are embarrassing obstacles to France’s nuclear technology export ambitions. And French regulators added injury to insult last week by revealing that weak areas with excessive levels of carbon detected in Flamanville’s steel RPV could also be present in two EPRs that AREVA was due to complete this year and next in China.

The shutdown of Belgium’s Doel 3 and Tihange 2 reactors, meanwhile, put that country on blackout alert this past winter and delayed the next phase in integrating Europe’s power markets.

Electrabel argues that the hydrogen flakes in those RPVs are the result of previously undetected errors in the forging process. It insists that their steel is stable, and is seeking to convince Belgium’s Federal Agency for Nuclear Control that the RPVs remain sufficiently robust to justify continued operation.

In February, however, the director general of FANC, Jan Bens, told Belgium’s state broadcaster that the flaws could be a “global problem” for the nuclear industry [in Flemish]. “The solution is to implement ... inspections of all 430 nuclear power plants,” said Bens.

It is not a particularly onerous suggestion. RPVs are routinely subjected to ultrasonic inspection on the welds that fuse together their steel plates. The test that revealed the hydrogen flakes in Belgium’s RPVs—which Bens is advocating should be repeated worldwide—is simply extending the ultrasonic sensing to the steel plates themselves.

Other European regulators appear to be warming to the idea. Spanish regulators insisted on a comprehensive ultrasound inspection of the RPV at the Garona nuclear power station before issuing an extended operating license for the 44 year old plant. Last month Garona's owner, Nuclenor, announced that the completed inspections show its RPV to be free of defects.

Several prominent materials scientists are backstopping Bens’ call for broader RPV inspection. Digby Macdonald, a corrosion expert at the University of California at Berkeley, says it is possible that hydrogen flakes such as those found in Belgium’s reactors could arise in high-grade steel of RPVs as a result of their operation. He cites a phenomenon called hydrogen blistering that afflicts petrochemical reactor vessels: hydrogen atoms diffuse into the steel matrix and then, once inside, combine to form hydrogen gas. “That gas then expands and literally blows apart the steel,” says Macdonald.

Macdonald says that, contrary to Electrabel’s early arguments that there was no ready source of hydrogen in its RPVs, hydrogen from the reactor’s cooling water would “easily” diffuse through the RPVs’ stainless steel surface. This was not recognized, he says, because the initial review panels focused on fracture mechanics. “They had no corrosion expertise on their panel,” he says.

Mandating more comprehensive ultrasound inspection across all RPVs only makes sense, says Macdonald, to identify whether hydrogen flaking is more widespread and whether it is something that worsens over time. “If hydrogen flakes are growing, there is reason for concern because at some point the pressure vessel will be compromised. It’s prudent that they examine all the reactors.”

In the U.S. it comes down to the NRC, says Macdonald, because it sets the level of risk that is acceptable. “The utilities are only going to do what the NRC dictates. So it’s really NRC’s responsibility to assess whether this represents a danger to integrity of pressure vessels,” he says.

IEEE Spectrum requested an interview with an NRC expert to discuss the agency’s ultrasonic testing requirements, and whether broader testing should be required. An NRC spokesperson responded with a written statement acknowledging Professor Macdonald’s “point of view” and asserting that “the existing U.S. inspection process is appropriate for detecting reactor pressure vessel issues.”

Peter Fairley has been tracking energy technologies and their environmental implications globally for over two decades, charting engineering and policy innovations that could slash dependence on fossil fuels and the political forces fighting them. He has been a Contributing Editor with IEEE Spectrum since 2003.