Brazil Doubles Down on Biofuel

Start-up GraalBio wants to transform sugarcane waste into cellulosic ethanol

Later this year, northeastern Brazil will host one of the most ambitious biofuel experiments ever. There, in the small town of São Miguel dos Campos, surrounded by sprawling sugarcane fields, a commercial-scale ethanol plant is expected to start operating in December. Unlike the nearby ethanol plants, which use sugarcane as feedstock, this new facility will consume the leftovers of those plants—bagasse and straw—to produce a holy grail of biofuel: cellulosic ethanol.

Ethanol produced from corn has gotten a bad reputation in recent years. Turning food crops into fuel might help drivers fill up their tanks, but it also raises food prices. What’s more, studies have shown that production of corn-based ethanol actually increases carbon emissions rather than reducing them. Because cellulosic ethanol is made from agricultural waste and nonfood crops, it has none of those drawbacks.

The prospect of transforming cheap raw materials like sugarcane bagasse, switchgrass, wood chips, wheat straw, and corn stover into fuel has led to a worldwide race for technologies that can make cellulosic ethanol commercially practical. But success has eluded big companies and start-ups alike. It costs more to make ethanol from cellulose than from corn or sugarcane because of the extra equipment, chemicals, and steps involved.

Now a Brazilian start-up, GraalBio, thinks it can overcome those obstacles by combining state-of-the-art ethanol-processing technology from an Italian supplier, advanced biomaterials from a Danish firm, and the favorable conditions of the Brazilian state of Alagoas, whose large sugarcane industry produces abundant waste that it can use as feedstock.

The US $150 million facility that GraalBio is building will be South America’s first and one of the world’s only commercial-scale cellulosic ethanol plants. It’s expected to produce 82 million liters (22 million gallons) of cellulosic ethanol per year, or more than 10 times the output of existing pilot and demonstration facilities. The plant is likely to be one of the world’s most closely watched energy projects this year as the continuing instability in oil prices puts biofuels back in the spotlight.

Helena Chum, a research fellow with the U.S. National Renewable Energy Research Laboratory, says one of the advantages of the GraalBio project is that it includes “the whole cycle” of cellulosic ethanol production—from abundant feedstock to a large ethanol market. “This bodes very well for the field,” she says.

Brazil’s thirst for ethanol is perhaps greater than any other nation’s. Nearly every car sold in the country has a “flex fuel” engine, capable of running on gasoline, ethanol, or any mix of both. But the country’s much-praised ethanol program lost momentum when weak sugarcane harvests, low sugar stocks globally, and increased consumption worldwide brought surges in ethanol fuel prices. The Brazilian government didn’t help, either: Its investments in biofuels slowed down after the discovery of massive offshore deepwater oil reserves. As a result, the country is struggling to meet domestic demand, with a deficit of 1 billion liters annually, according to one estimate.

That’s the opportunity GraalBio wants to explore. It claims that using sugarcane waste as feedstock could expand the country’s production by 35 percent. And how does the company plan to succeed where others have failed? In part, by acting as an integrator that combines the most advanced technologies available, says GraalBio founder and president Bernardo Gradin. According to Gradin, an engineer with a Wharton MBA and a former chief executive of Braskem, one of Brazil’s largest petrochemical groups, there’s no shortage of technologies out there. What the industry needs, he says, is more people willing to put the parts together and scale them up. “What we are trying to do is innovate the business model,” he says.

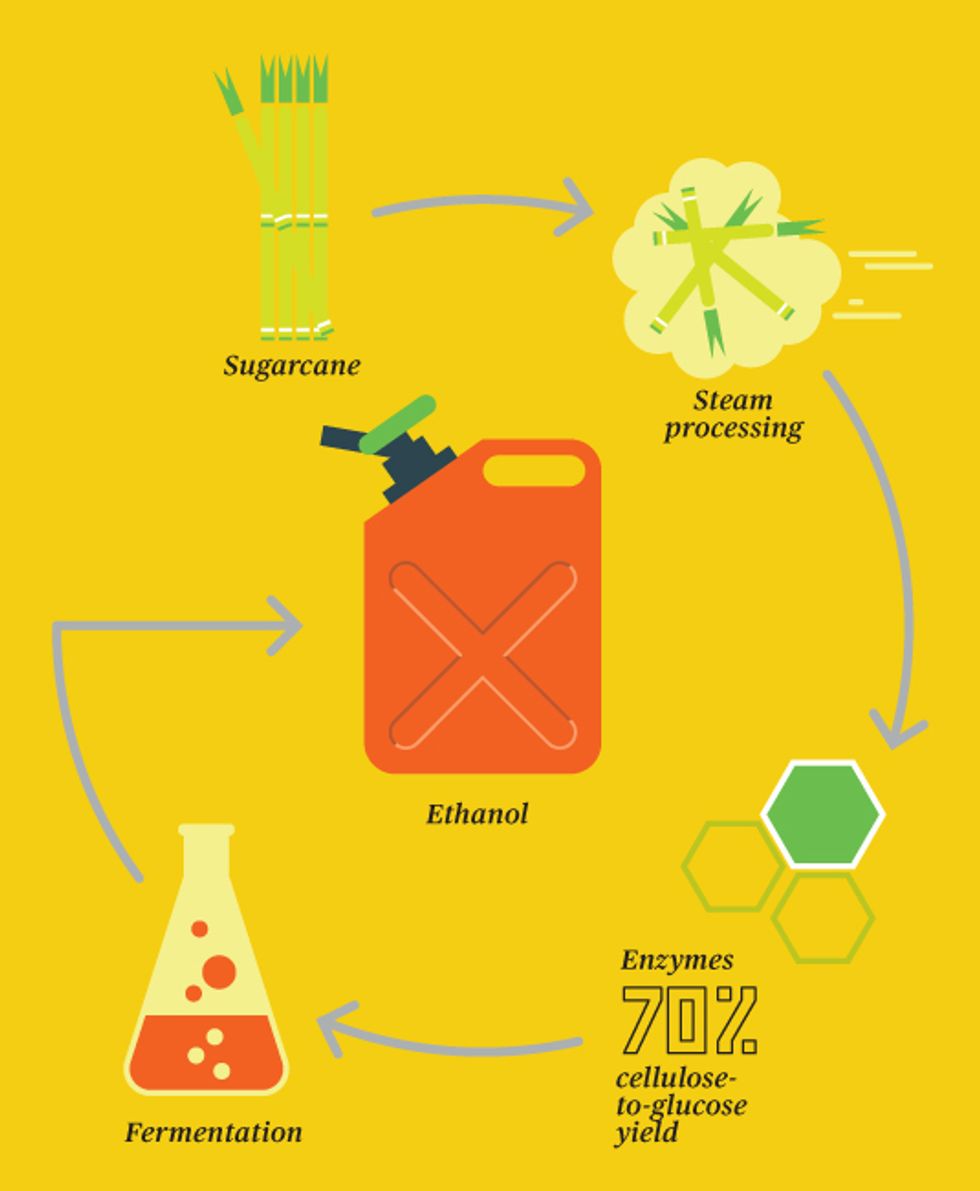

Transforming cellulose into ethanol requires several steps. First you have to pretreat the biomass to break down its tough cellular structures, which typically involves processing with vast amounts of acids and other substances. Instead, GraalBio will use a chemical-free method that applies high-pressure steam to the raw materials to loosen up their cells. The company is licensing this technology, called Proesa, from Beta Renewables, owned by Italian conglomerate Mossi & Ghisolfi.

Next you need enzymes to break down the cellulose into simple, fermentable sugar molecules. It doesn’t sound like high-tech stuff—cattle, sheep, and termites have such enzymes in their guts. But to process lots of feedstock cheaply, you need the best enzymes, and finding and tweaking them genetically has become a cutting-edge subfield of biotechnology.

One of the top companies in this area is Novozymes, based in Bagsvaerd, Denmark. About five years ago, the company’s CTec2 enzyme had a glucose yield of up to 70 percent for corn stover but only about 30 percent for bagasse. More recently the company reported that its CTec3 enzyme produced glucose yields of about 70 percent for both corn and bagasse. That’s the enzyme GraalBio will use.

And using sugarcane waste is just the beginning. The company hopes to create a new variety of cellulose-rich cane by crossing varieties of sugarcane with select types of grass. This “energy cane” could produce 300 metric tons of biomass per hectare in comparison to the 80 metric tons produced by regular sugar cane, says Gonçalo Pereira, the company’s chief scientific officer, who runs GraalBio’s newly built research center in Campinas, about 100 kilometers northwest of São Paulo. Pereira is also developing the company’s own yeast strains, hoping to boost the fermentation process. And a new, improved water waste process and biomass storage will allow GraalBio’s mills to run for most of the year, unlike traditional ones. These and other advances will be critical, Pereira says. “There will be companies that use the exact same biomass, and one will be profitable and one will be a disaster.”

Still, it’s a bold gamble, given cellulosic ethanol’s history. Several attempts at large-scale production have ended up in failure in the United States, Canada, and other locations. GraalBio is confident in the success of its first plant. So confident, in fact, that it’s already planning to build five more plants by 2017. The Brazilian government will help with financing. The Brazilian Development Bank recently tripled its budget for advanced biofuels to $1.5 billion and approved projects from 25 companies, GraalBio among them.

“People spent a lot of money on [cellulosic ethanol] and have not seen any results,” says Arnaldo Vieira de Carvalho, a senior energy specialist at the Inter-American Development Bank in Washington, D.C. More recently, he adds, the technology has gotten cheaper, so new plants have a better chance at succeeding. “But given past experience, I take the wait-and-see approach.”

About the Author

Vinod Sreeharsha is an American journalist based in São Paulo, Sreeharsha covers politics, economics, technology, and entrepreneurship in South America. He has written for The New York Times, The Miami Herald, and VentureBeat. Sreeharsha says he relocated to Brazil because it’s “a deeply complex nation—the more you learn, the more you realize you don’t know.”