1 March 2012—Engineers at Pennsylvania State University have combined two cutting-edge energy-generation technologies—microbial fuel cells and reverse electrodialysis (RED)—to make a hybrid device that could generate enough energy from wastewater to power its treatment and even feed some extra electricity into the grid. The engineers report their invention this week online in Science.

“The goal I’ve been pursuing is to ensure the energy sustainability of the water infrastructure,” says Bruce E. Logan, the professor of civil and environmental engineering who led the research. The energy potentially available in municipal wastewater is surprisingly high—more than nine times as high as what’s needed to process it. “It wouldn’t take much to think we could be at least energy neutral,” he says.

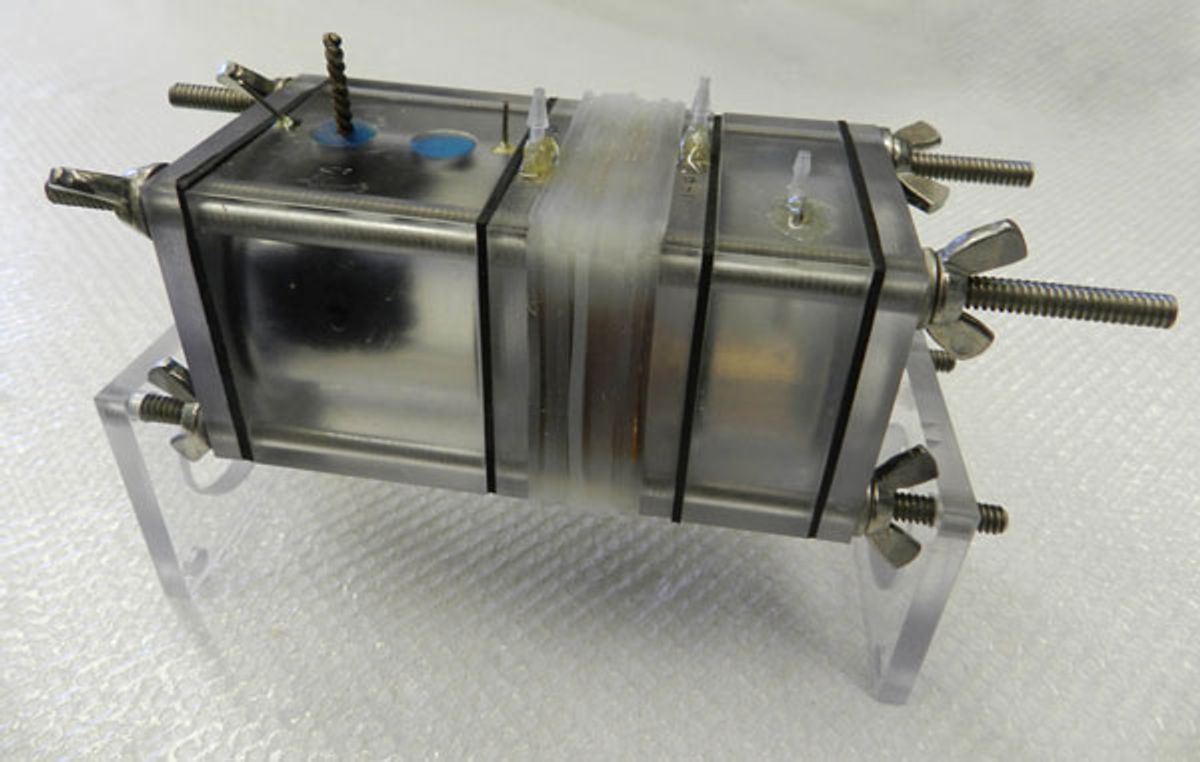

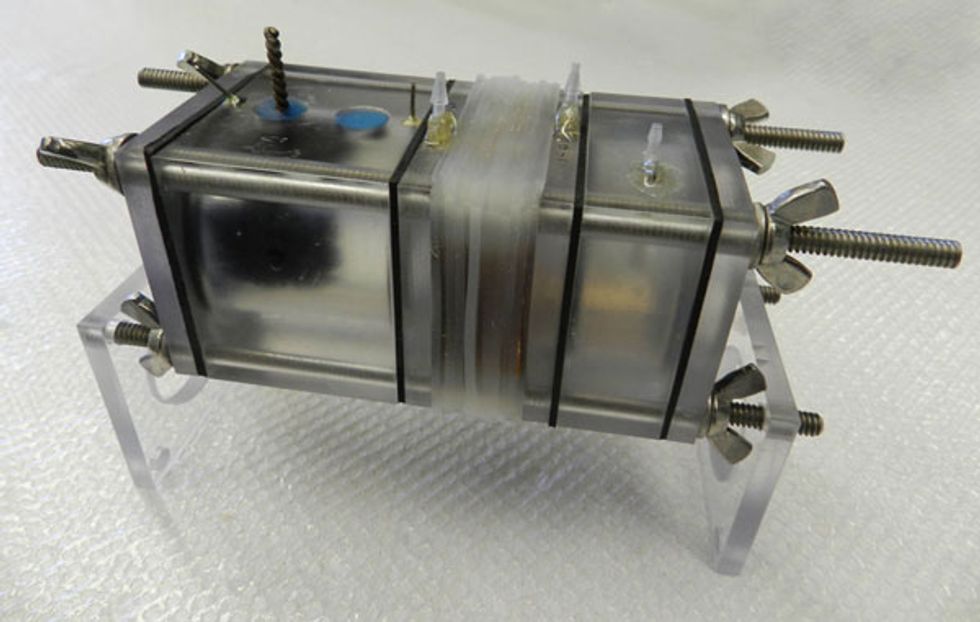

A microbial fuel cell is much like a battery. In many designs, a water-filled chamber is divided in two by a semipermeable membrane that allows protons to flow through in one direction. An electrode in each chamber connects the chambers to whatever is to be powered by the fuel cell, forming a circuit. In one chamber, microbes attached to the electrode munch organic molecules in wastewater. As they do this, they split the molecules, giving off electrons, protons, and simpler molecules such as carbon dioxide. The protons pass straight through the membrane, setting up an electric potential between the two chambers. The electrons flow from the electrode through the circuit to the other chamber, where they combine with the protons and oxygen to make water.

RED also depends on the flow of ions but uses a difference in the concentrations of ions dissolved in water as the driving force. It relies on two types of membranes, one that allows only negative ions to flow through and another that allows only positive ones to pass. Imagine dividing a channel into three parts by separating one side using the negative-ion membrane and the other side with the positive-ion membrane. If you flow saltwater through the center channel and freshwater through the two side channels, osmotic pressure will drive the ions across their respective membranes. One side channel becomes negative and the other positive—essentially creating a battery.

Both schemes have been under intense study, but each has a big drawback. Microbial fuel cells produce little power, and RED cells must be stacked up in a series of at least 20 pairs of membranes, which don’t come cheap.

Combining the two technologies overcame both weaknesses, says Logan: “It’s like a turbocharger.” The combination lowered the number of stacks required for RED to 5 instead of 20 and raised, by more than seven times, the amount of power the fuel cell generated when fed a diet of domestic wastewater.

“It’s taking the best of both worlds,” says Eric Hoek, associate professor of civil and environmental engineering at the University of California, Los Angeles, whose research includes improving membranes for osmotic processes including RED.

Critical to the hybrid’s success was the use of ammonium bicarbonate salt, a “thermolytic chemical,” instead of saltwater. The salt can be separated from the solution by heating it to a little more than 40 °C , allowing it to be recycled using waste heat from industrial processes. The thermolytic trick was pioneered by Yale University environmental engineering professor Menachem Elimelech for use in both a desalination technology called forward osmosis and a power-generation scheme known as pressure-retarded osmosis.

According to Elimelech, scaling up Penn State’s hybrid device will require overcoming technical issues associated with both RED and microbial fuel cells. “Scaling is always an issue,” says Elimelech.

Finding an opportunity to prove the scaled up technology in a real-world installation is a recurring problem in the water industry, as municipalities are famously conservative about trying new technologies that haven’t succeeded elsewhere. Logan believes the hybrid technology’s early adopters would likely be communities in developing countries that lack easy access to reliable electricity. But he’s confident that the developed world will eventually see the attraction, too.

“It’s a way to make a necessary process potentially energy neutral or even energy positive,” says Hoek. Besides, it’s not as though the raw materials were in short supply. “Wastewater is probably the only raw material that increases with population and industrial development,” Hoek points out.