Doxel is a startup that came out of stealth this week with a US $4.5 million funding round. Their business is making construction cheaper, and their secret (as with so many startups now) is combining massive amounts of data with deep-learning techniques.

Using lidar-equipped robots, Doxel scans construction sites every day to monitor how things are progressing, tracking what gets installed and whether it’s the right thing at the right time in the right place. You’d think that construction sites would be doing this by themselves anyway, but it turns out that they really don’t, and in a recent pilot study on a medical office building, Doxel says it managed to increase labor productivity on the project by a staggering 38 percent.

The concept behind Doxel is straightforward enough: Construction projects have plans and budgets and timelines. If you stick to the plan, the budget and timeline (the things you really care about) should be what you expect. But construction projects with plans and budgets and timelines all depend on a big pile of humans doing exactly what they’re supposed to do, and we all know how often that happens. With that in mind, it may or may not surprise you to learn that 98 percent of large construction projects are delivered (on average) 80 percent over budget and 20 months behind schedule. According to people who know more about these sorts of things than I do, productivity in the construction industry hasn’t improved significantly in 80 years.

A big part of the problem is simply keeping track of what gets done. Currently, the industry does this by sending people around with clipboards and tape measures, because throwing more humans at a problem caused by humans is definitely the best idea, right? Doxel’s idea is to get rid of the humans entirely, and instead rely on data. And robots.

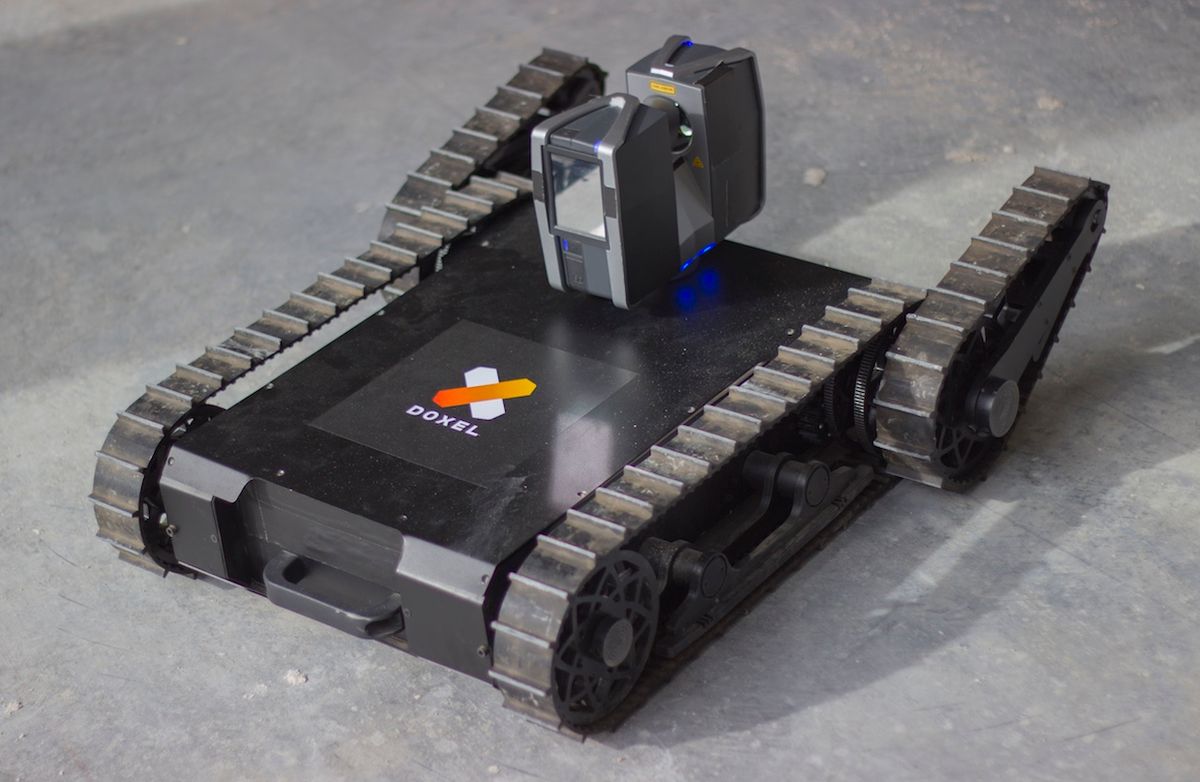

Doxel mostly focuses on what’s going on inside a construction site, since that’s where the majority of the complicated stuff happens. Once the construction site shuts down for the day (usually in the late afternoon), Doxel sends in a cute little autonomous robot with an excellent lidar on it to methodically scan the entire site. The robot has no problem following prescheduled paths that can include stairs, and just one of these little things can scan about 30,000 square meters over the course of a week.

Once the robot is finished, it sends all of that data to the cloud, where it gets chewed on by Doxel’s 3D semantic deep-learning algorithms, which have been trained to recognize all kinds of components (even if only a tiny bit of them is visible) based on shape, location, and size. The accuracy of the lidar map that Doxel creates allows them to verify that the right things have been installed correctly and in exactly the right place. If they have, Doxel can quantify that progress, and if they haven’t, Doxel can send in the killbots. Or, they can just let managers know so that they can take steps to fix things immediately.

This is part of what makes the productivity savings so significant—you don’t have to go back later and fix problems that you only notice weeks later when those problems have caused other problems.

This all sounds like a good idea, but how much of a difference does it actually make? Doxel shared a recent case study with us, where they helped supervise construction on a multifloor medical office building in San Diego, Calif., which the robot could autonomously scan in its entirety in 4.5 hours, which it did every day. Over the course of the project, there was an increase of labor productivity of 38 percent over the original estimate in the project budget, which resulted in the project as a whole coming in 11 percent under budget. Sure, that’s just one example, and not all projects will achieve similar results. But again, in the construction business even more modest results would be hugely significant.

While we may be fixated on the robots, Doxel is mostly about interpreting the data that they collect, and the robots are simply the most efficient and cost effective way to go about it. You could send in some humans with lidar backpacks, but that would be more expensive. The company is also using drones in a limited capacity right now, since they require human supervision, but it’s easy to imagine how much more efficient this process could get as robotic autonomy improves.

[ Doxel ]

Evan Ackerman is a senior editor at IEEE Spectrum. Since 2007, he has written over 6,000 articles on robotics and technology. He has a degree in Martian geology and is excellent at playing bagpipes.